Enersol Pool Panel Installation Guide

7 |

P a g e

ASSEMBLY INSTRUCTIONS

(CONTINUED)

2 - Roll out panels on roof, rack or

ground:

a)

Carry the boxes to the installation area.

b)

If installing on a roof

– snap a chalk line as a

guide to where the top of the panels will be

aligned. It is important to place the panels on

a slight angle on the roof. This helps purge

the air from the system when filling, and

provides drainage when draining for the

winter. Angle the panel headers

4” for every

40 feet with the slope down toward the end

that has the feed line

Remove from box carefully and unroll

panels. If panels become tangled, lay

flat and untwist strips from one end to

the other

c)

Carefully take the sections out of the box

(give each roll a twist to tighten and pick up

from the bottom to prevent tangling), set

down, evenly arrange, and allow each

section to unroll.

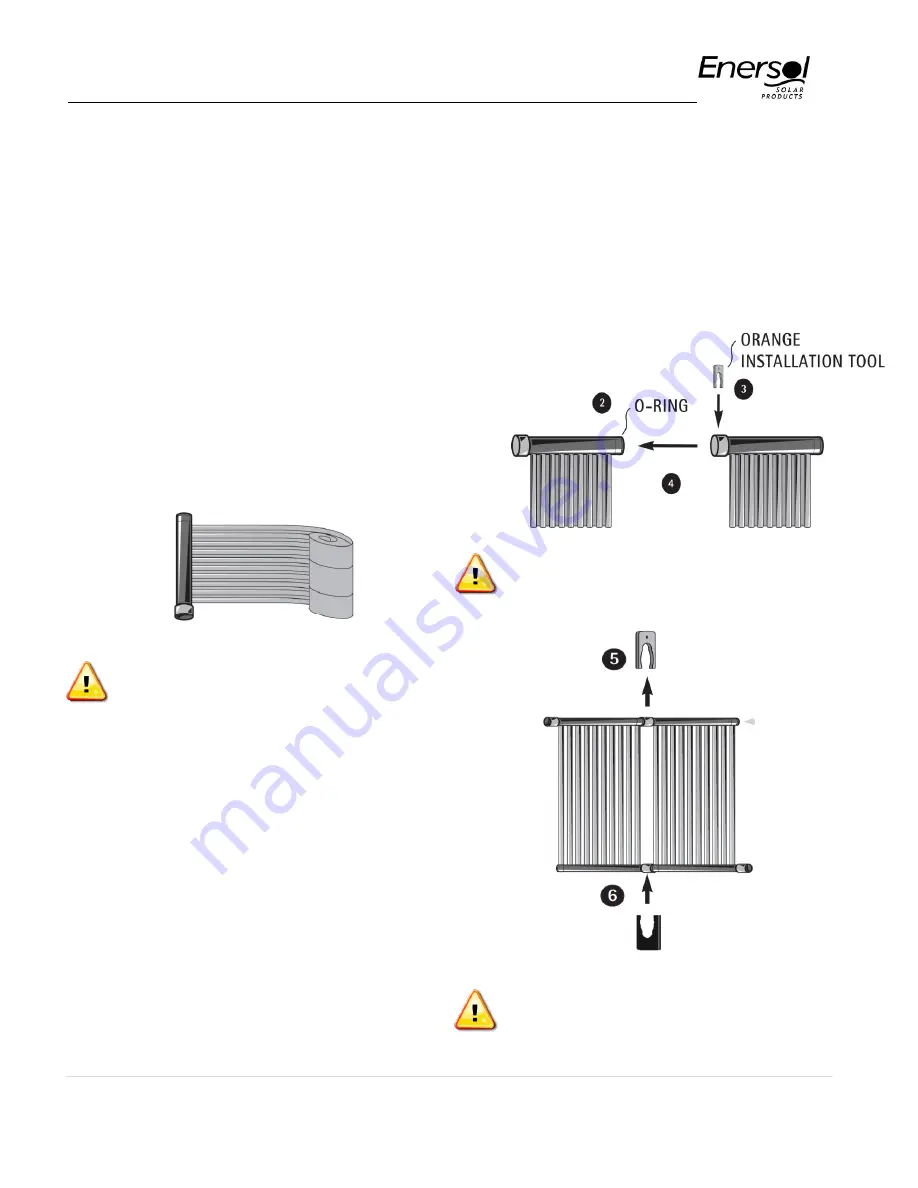

3 - Clip together using the installation

tool included with the required

System Kit.

a)

Keep the top header close to the reference

chalk line as you begin the assembly.

1

put an O-ring on the first header

2

lubricate the O-ring, with supplied lubricant

(lithium based)

3

clip the orange installation tool into the slot

on the next header

4

push the two sections together

5

remove the installation tool

6

insert black clip to complete the connection

b)

Continue this procedure for the top headers

until all the panels are connected.

The orange installation tool must be

used to prevent damage to the O-rings

When connecting different versions of

headers, always cut off locator tab

before connecting.