Enersol Pool Panel Installation Guide

8 |

P a g e

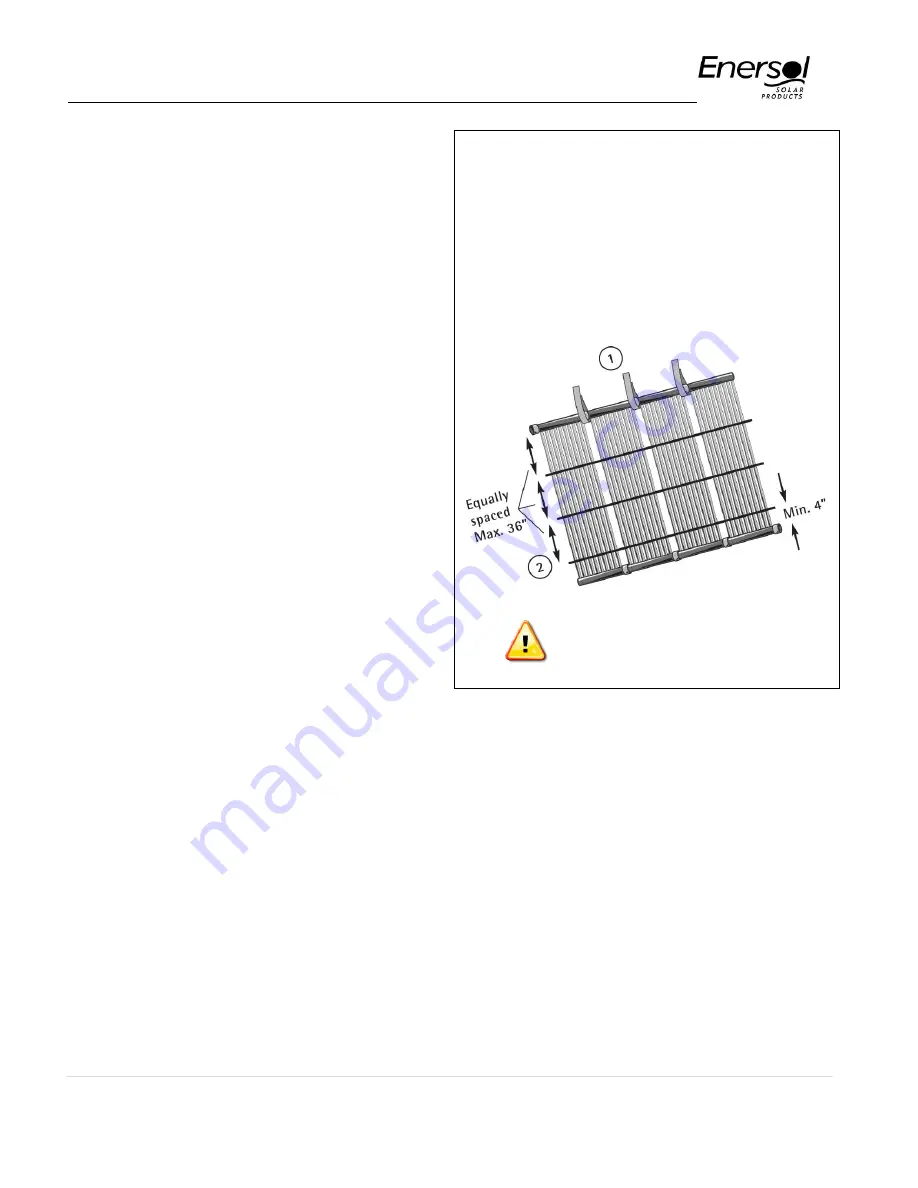

4 - Strap down headers and panels

a)

Starting at the top end, secure the headers

to the

roof by placing header straps (12”

long) on every clip connection.

b)

Loop the strap around the top header, bring

the two grommets together and push the

threaded lag bolt through the grommets.

Check for proper tension, apply a generous

dab of roof sealant on the chalk line and

secure the lag bolt to the roof. Repeat this

for every header until complete the top row

strap installation.

c)

On steeper roofs, you may want to strap the

headers one at the time while you are

making the connections to prevent the entire

assembly from slipping down.

d)

Always straighten the bottom headers by

pulling gently and join together as the top

headers (see step 3), Bottom headers are

not strapped down.

e)

To complete the securing process, cross

strapping (48” long) is used. The straps are

attached grommet to grommet across the

entire width of panels. Starting from the top,

the cross straps should be equally spaced at

no more than 36 inches apart. Fasten using

the proper lag bolts and roof sealant

provided. The last row, nearest to the bottom

should be no more than four inches from the

bottom header. Bottom headers are not

strapped down to allow for expansion and

contraction of the panels. When installing

longer custom sizes panel they may require

additional horizontal strapping.

f)

If your roof has a membrane, or cannot be

punctured, it is possible to attach a lumber

frame to the roof with liquid nails adhesive

and attach the lag bolts into the lumber.

(Contact your roof manufacturer for advice).

Attach to Roof

1 Top strap:

Install a strap every section across top

only.

2 Cross Strap:

Install Cross strapping equally

spaced along the length of the collector, making

sure to leave at least 4 inches from bottom. Do not

over tighten cross strapping, to allow for expansion.

Apply a generous amount of roofing cement. Screw

lag bolts through roofing cement into roof. Use roof

sealant liberally with all lag bolts into roof.

Never use top straps on bottom

headers

PLUMBING

5 - Connect Plumbing

Join Plumbing to Headers

a)

The Header End connector (HEC) included

in your system kit creates a male and a

female adapter.

Clip the header end connectors (HECs) to

the headers, diagonally opposite of one

another, at the input and output of the array

so that the plumbing can be glued to the

HEC instead of the header.