8

C048-784-30 R01, Rev. B (03/2021)

4.2.2

4.2.2 Optional Rear Rack Support Kit

Optional Rear Rack Support Kit

(C750-277-10)

(C750-277-10)

An optional telescoping rear rack support kit is available to help secure

the panel to the rear of the equipment rack and to distribute panel weight

evenly� In addition to the standard lacing bar included with the TPA 250

Series fuse panel, a new lacing bar is included with this kit which can be

repositioned on any of the available lacing bar holes depending on the

depth of the equipment rack� Use a hex key to relocate the new lacing

bar if needed� See Appendix A for mechanical dimensions of rear rack

support kit�

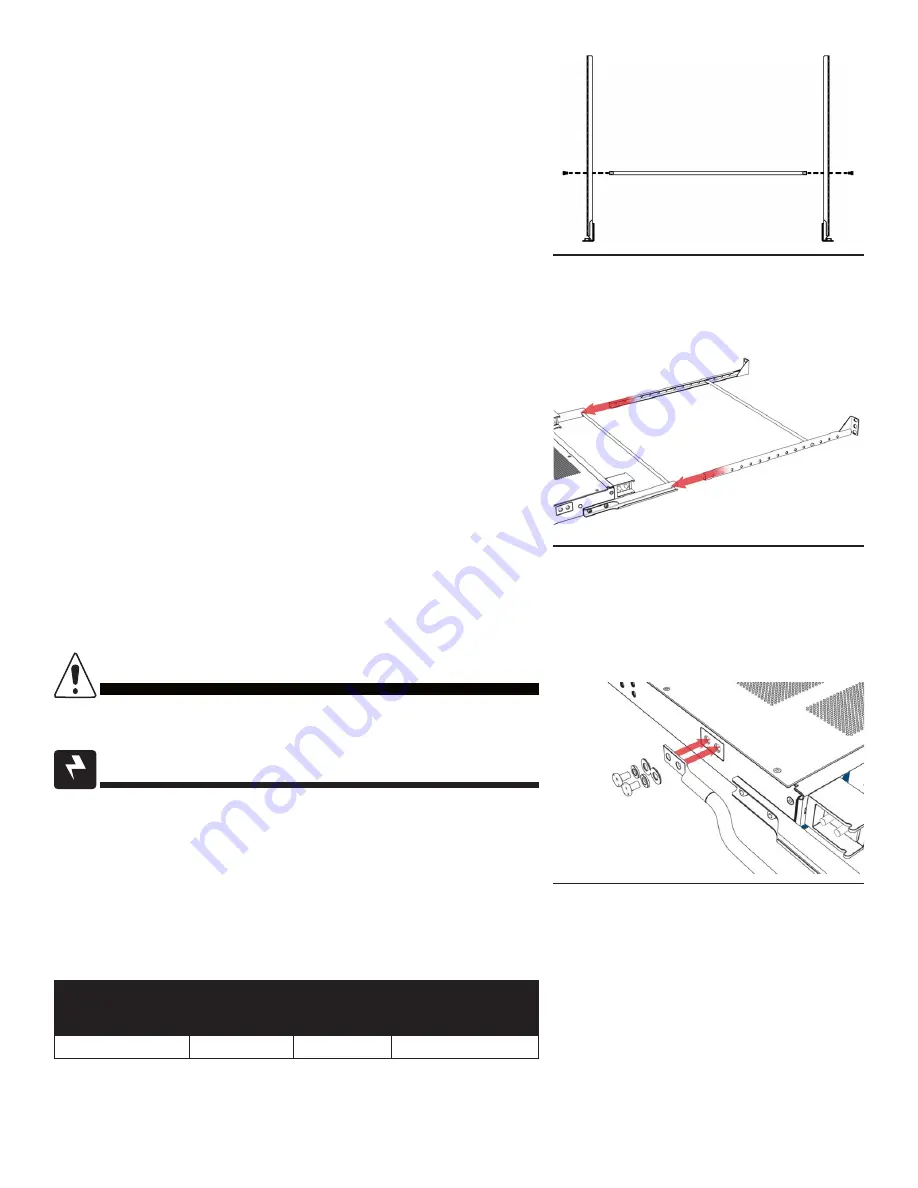

Step 1.

Install the shorter cable lacing rod in between the left and right

lacing bar brackets by tightening a supplied 10-32 socket head

screw into each end of the threaded rod (see Figure 5 on Page 7)�

Step 2.

Attach the cable lacing bar assembly to the fuse panel by

tightening (2) 10-32 socket head screws per side into the

threaded holes located on each side of the fuse panel chassis

towards the rear (see Figure 6 on Page 7)�

Step 3.

Install the longer cable lacing rod in between the left and right

lacing bar rear support rails by tightening a supplied 10-32 socket

head screw into each end of the threaded rod (see Figure 7)�

Multiple mounting holes are provided in the rails for optimal lacing

rod positioning�

Step 4.

Slide the rails of the rear rack support assembly into the lacing

bar assembly (see Figure 8)�

Step 5.

Secure the mounting ears to equipment rack via the slotted holes

or threaded inserts�

4.3

4.3 Chassis Ground

Chassis Ground

DO NOT ENERGIZE THE PANEL BEFORE CHASSIS

GROUND IS CONNECTED�

CAUTION!

WARNING! ELECTRICAL HAZARD

DO NOT USE HARDWARE WITH A LENGTH EXCEEDING

3/4 INCH FOR CHASSIS GROUND CONNECTIONS�

The chassis ground is located on both sides of the panel� Two-hole

lug landing positions are provided� See table below for termination

information� A minimum of #4 AWG chassis ground cable is required�

IMPORTANT: Grounding hardware not included. A properly-sized

grounding conductor must be installed per NEC (250�122)�

Table 2.

Chassis Ground Termination Specifications

TERMINATION

TYPE

HOLE/STUD

SIZE

CENTER

TO CENTER

RECOMMENDED

TORQUE VALUE

Threaded insert

1/4 in�

5/8 in�

6.25 ft∙lbs

Step 1.

Secure the ground cable to the chassis by tightening 1/4 in�

hardware (see Figure 9)�

Figure 7. Cable lacing rod

(for rear rack support kit)

Figure 8. Rear support rails

(for rear rack support kit)

Figure 9. Chassis ground