regulating piston forward until it

seals in port "P". This cuts off the oil

low to the nozzle and ensures that

the nozzle line is effectively shut off.

If the pump is overloaded, i.e. more oil

is demanded than the gearwheel is

able to pump under the given condi-

tions, the oil pressure falls below the

set value because the piston of the

regulating valve moves towards its

closed position and partially or wholly

cuts off the return oil via port "O".

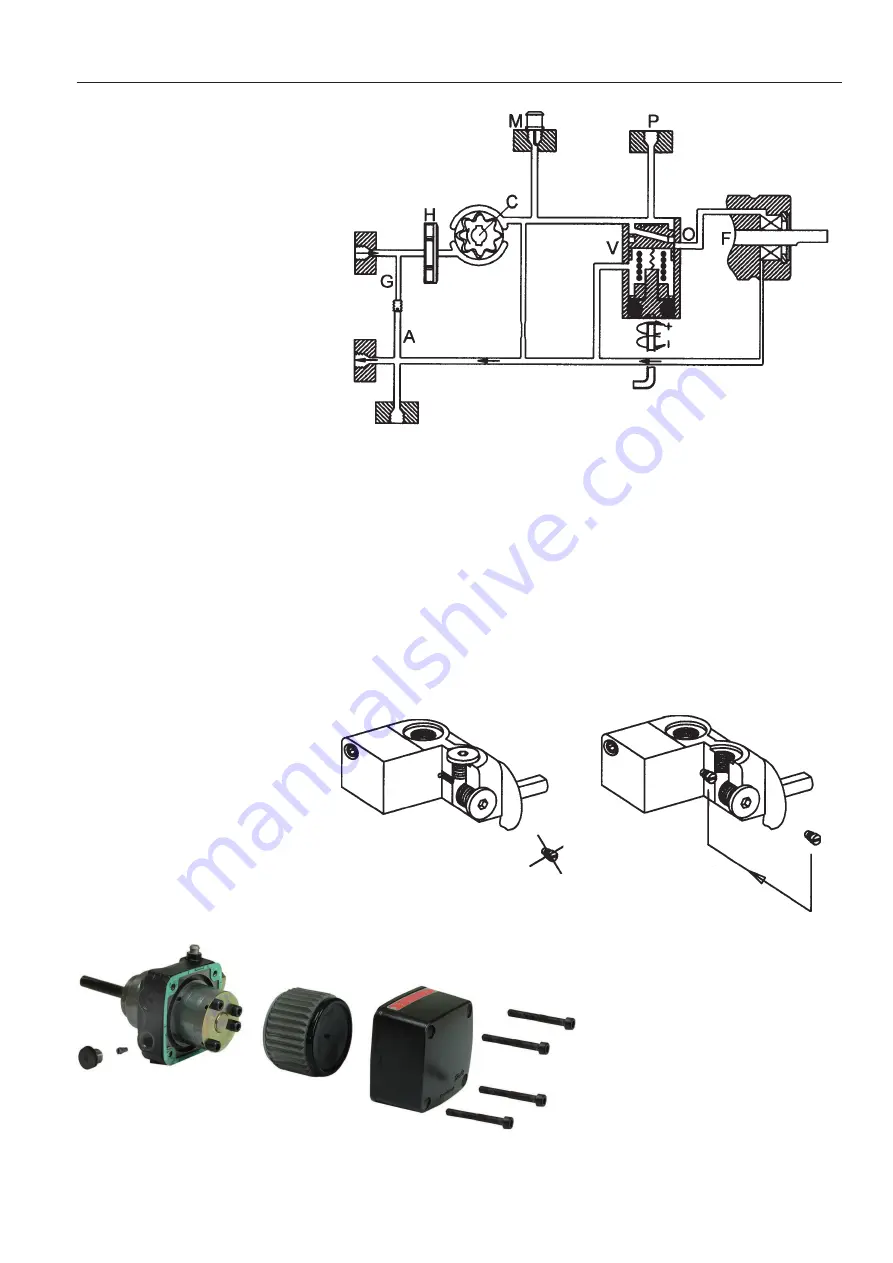

Two pipe system

Mounting/dismounting by-pass plug

In a 2-pipe-system excess oil is

led back direct to the oil tank. In a

1-pipe-system the by-pass plug

must be removed so that there is

a free passage back to the suction

side through the return line with the

return port closed.

Exchange of ilter

One pipe system

Function DANFOSS RSA 95 - 125

When the pump is started oil is

drawn through the suction port "S"

via ilter "H" to the suction side of the

gearwheel set "C". From here the

gearwheel set pumps the oil to the

pressure side and at the same time

the oil becomes pressurized. The oil

is led to cut-off and regulating valve

"V" which opens when the set pressure

is reached.

The pressure is controlled and kept

constant by regulating valve "V". At

the same time the gearwheel set

"C" distributes the oil through nozzle

port "P" and pump return side "R"

via the shaft seal "F".

The quantity of oil supplied to nozzle

port "P" is determined by the pressure

set on regulating valve "V" and the

nozzle/resistance in the nozzle line.

In 2-pipe-systems excess oil is led

back to the oil tank. In 1-pipe-systems

the by-pass plug "A" must be removed

to give free low back to the suction

side via return line "G" with return port

"R" closed.

When the pump is stopped, the

pump output drops and produces a

drop in the oil pressure. The spring

in the regulating valve presses the

171 505 39 10-01

This can be remedied by

-

reducing the pump pressure

-

reducing the capacity, i.e. smaller

nozzle or greater resistance

-

changing to a pump with higher

capacity

INSTRUCTIONS PUMP TYPE DANFOSS RSA 95-125

R

S

Summary of Contents for Bentone B70-2.3H

Page 2: ......

Page 5: ...14 205 5 310 324 380 TECHNICAL DATA 171 225 77 10 01 Dimensions of lange...

Page 19: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...