6

010.1220.0719 01.21

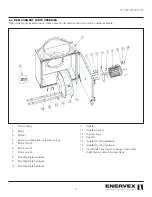

2. SPECIFICATIONS AND DIMENSIONS

2.1 Specifications

Fan Type

Motor

Voltage Configuration

Motor Rating

Max Speed

Max Motor Torque

EDrive Model

EDrive Rating

Supply Voltage

Power

Max Input Current

Max Output Current

Operating Temperature

A - in / mm

B - in / mm

C - in / mm

D - in / mm

E - in / mm

F - in / mm

G - in / mm

H - in / mm

Weight

BEF 315x

1x120 / 3x240 V

2100 RPM

3.0 Nm

321.2208.1200

321.2208.2200

1x120 / 3x240 V

0.75 kW

15.8 / 5.6 A

4.3 / 4.3 A

22.64 / 575

30.79 / 782

12.60 / 320

7.12 / 181

9.80 / 249

24.41 / 620

11.34 / 288

1.97 / 50

84 lbs / 38 kg

BEF 355x

1x120 / 3x240V

1950 RPM

3.0 Nm

321.2208.1200

321.2208.2200

1x120 / 3x240V

0.75 kW

15.8 / 5.6 A

4.3 4.3 A

25.00 / 635

33.35 / 847

13.11 / 333

7.12 / 181

11.77 / 299

24.41 / 620

12.48 / 317

1.97 / 50

99 lbs / 45 kg

BEF 500x

3x240 / 3x480V

1750 RPM

24.0 Nm

321.2214.2200

321.2214.4200

3x240 / 3x480V

5.5 kW

26.4 / 17.2 A

24.0 / 14.0 A

33.54 / 852

42.36 / 1076

16.42 / 417

9.06 / 230

19.65 / 499

31.50 / 800

16.77 / 426

1.97 / 50

208 lbs /95 kg

BEF 800x

3x480V

1750 RPM

137.9 Nm

321.2220.4200

3x480V

22.0 kW

51.9 A

46.0 A

51.26 / 1302

61.69 / 1567

24.09 / 612

20.83 / 529

35.83 / 910

41.77 / 1061

25.63 / 651

1.97 / 50

652 lbs / 296 kg

BEF 710x

3x480V

1750 RPM

70.0 Nm

321.2220.4200

3x480V

15.0 kW

34.2 A

30.0 A

46.10 / 1171

55.98 / 1422

22.36 / 568

14.57 / 370

31.46 / 799

45.71 / 1161

23.03 / 585

1.97 / 50

385 lbs / 175 kg

BEF 630x

3x240 / 3x480V

1750 RPM

50.0 Nm / 44.0 Nm

321.2218.2200

321.2218.4200

3x240 / 3x480V

11.0 / 7.5 kW

33.3 / 21.2

30.0 / 18.0

41.22 / 1047

41.26 / 1048

20.00 / 508

9.69 / 246

27.83 / 707

37.80 / 960

20.63 / 524

1.97 / 50

357 lbs / 153 kg

BEF 560x

3x240 / 3x480V

1850 RPM

50.0 Nm

321.2216.2200

321.2216.4200

3x240 / 3x480V

5.5 kW

26.4 / 17.2 A

24.0 / 14.0 A

37.09 / 942

45.43 / 1154

17.83 / 453

9.69 / 246

23.82 / 605

37.80 / 960

18.54 / 471

1.97 / 50

264 lbs / 120 kg

BEF 450x

3x240 / 3x480V

1500 RPM

6.0 Nm

321.2212.2200

321.2212.4200

3x240 / 3x480V

1.5 kW

12.1 / 7.5 A

10.5 / 5.8 A

30.60 / 777

39.80 / 1011

15.28 / 388

8.35 / 212

15.83 / 402

31.22 / 793

15.32 / 389

1.97 / 50

142 lbs/ 64.5 kg

Centrifugal

EC - motor

NEMA 3R / IP54

NEMA 4X / IP54

14-122°F / -10-50°C

BEF 225x

1x120 / 3x240 V

3100 RPM

3.0 Nm

321.2206.1200

321.2206.2200

1x120 / 3x240 V

0.75 kW

7.8 / 7.8 A

2.3 / 2.3 A

17.33 / 440

17.36 / 441

10.13 / 257

7.12 / 181

7.84 / 199

20.3 / 509

10.36 / 263

2.00 / 51

60 lbs / 27 kg

Summary of Contents for BEF 225x

Page 23: ...23 010 1220 0719 01 21...