CenCon

56

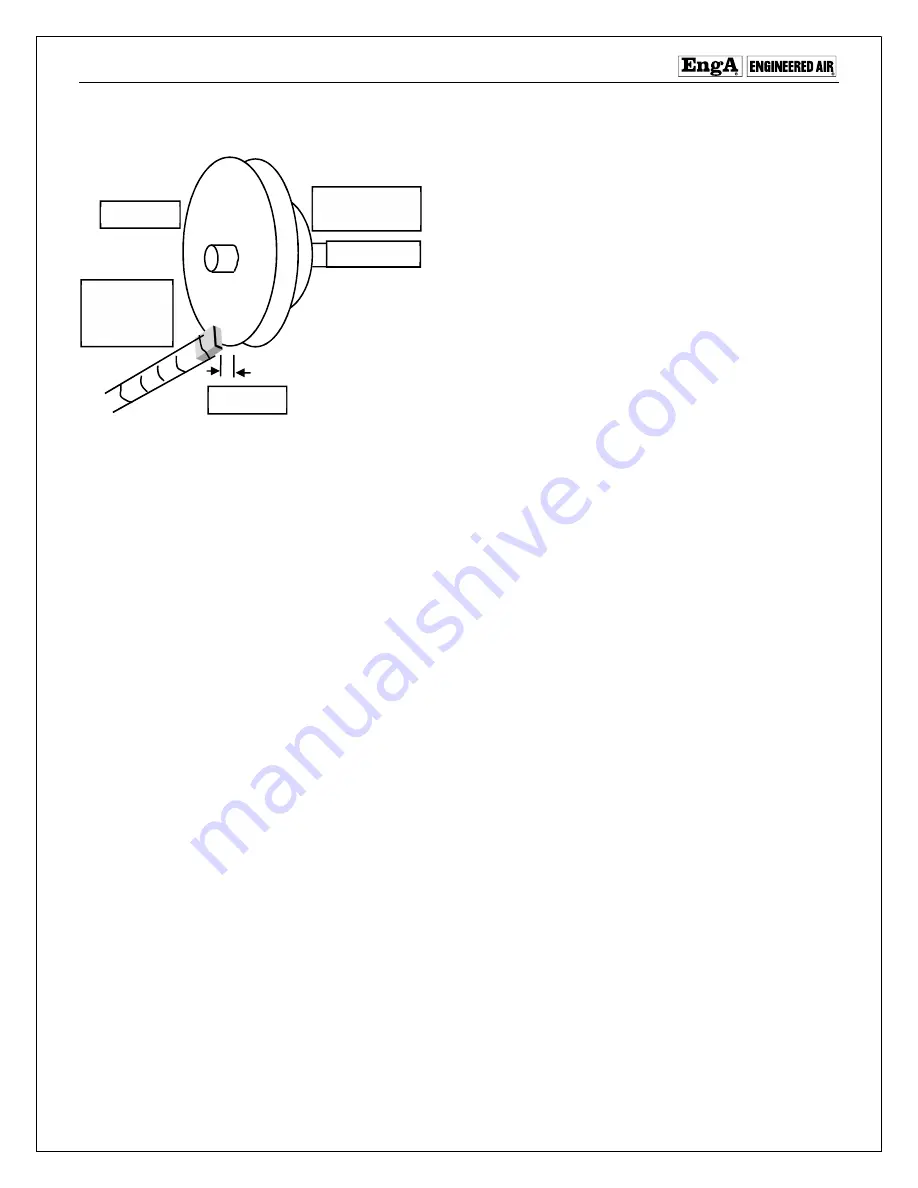

SPEED SENSOR – DJ

With a digital AC voltmeter, measure the AC volts present on terminals “YS to GS”. When the combustion

blower is running there should be 4 to 6 Vac present. If the AC voltage

is not present, check the tachometer

sensor to magnet gap. It should be 1/16 to 1/8 inch. If the gap is satisfactory, attempt to repair by flipping the

magnet over, then flipping the tachometer sensor over, before replacing the tachometer sensor to correct the

problem. Note: No part of the speed sensor’s sensing element should be located over the end of blower motor

shaft.

TOP LOADING

Ensure the top loading tube from the modulating valve is located is not pointed directly UP. Ideally it enters

from the bottom and is located at either side of the burner box and bent to a 90° angle pointed towards the

heat exchanger. This location was chosen to obtain reasonably constant pressure readings not affected by air

velocity.

AIR BALANCING

Installation and air balancing is often done during warmer weather than that experienced in the cold of winter.

If the air balance did not account for ambient temperature, the appliance could be having lower than expected

temperature rise in cold weather conditions. As the fan is a constant volume device and as it is located before

the heat exchanger, air will expand as it is heated. The amount of change could be up to a 20% increase in air

volume from -30°F to +70°F.

Blower

1/8”

Magnet

Magnet

Retainer

Hall

Effect

Sensor