A

DJM3

IOM-17

22 of 27 Mar 99 R3

TEMPERATURE

CONTROL

Modulation of the firing rate is gradually made until the discharge air temperature is within

1.5°F of

the “calculated” set‐point. When the heat load is light and the burner is cycling between low fire and

off there will be small temperature swings.

AIR

BALANCING

Installation and air balancing is often done during warmer weather than that experienced in the cold of

winter. If the air balancer did not allow for the changes that will occur in air volume in cold weather

then the unit will appear to be short of temperature rise. As the fan is a constant volume device and as

it is located before the heat exchanger, air will expand as it is heated. The amount of change will be

about 20% increase in air volume from ‐30°F to +70°F.

PRE

‐

PURGE

PROBLEM

If a Pre‐Purge problem is found, typically the DJM3 is receiving a signal from the tachometer sensor

(Hall Effect sensor) that is not consistent with the combustion blower status. If there is a call for heat

and the combustion blower is not running the DJM3 has likely detected a false or grounded

tachometer signal. Remove all three wires to terminals O, YS, and G. If the combustion blower fails to

start, check the combustion motor and or motor wiring.

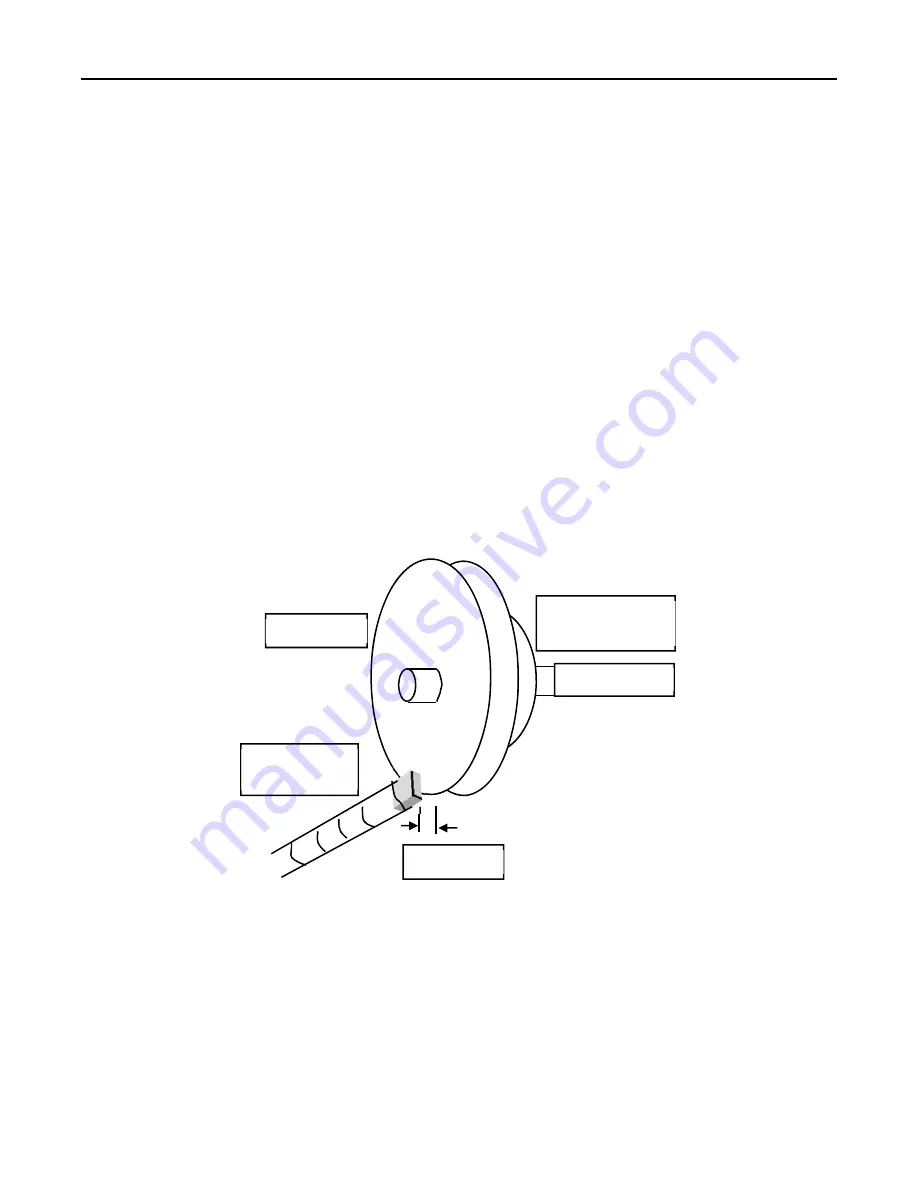

If the combustion blower is running and the tachometer signal is absent, weak, or grounded. With a

digital AC voltmeter, measure the AC volts present on terminals “YS to G”. When the combustion

blower is running there should be 4 to 6 Vac present. If the AC voltage

is not present, check the

tachometer sensor to magnet gap. It should be 1/16 to 1/8 inch. If the gap is satisfactory, attempt to

repair by flipping the magnet over, then flipping the tachometer sensor over, before replacing the

tachometer sensor to correct the problem.

Note: No part of the speed sensor’s sensing element should be located over the end of blower motor

shaft.

Blower Shaft

1/8” Gap

Magnet

Magnet

Retainer Ring

Hall Effect

Sensor