A

XES SC MANUAL

IOM-58

28 of 30

June 14 R5

OUTDOOR AIR INTAKES, MIXING SECTIONS AND DAMPERS

Outdoor air intakes, screens, and adjacent areas shall be checked semi-annually for cleanliness, integrity

and proper operation. Adjust dampers where required.

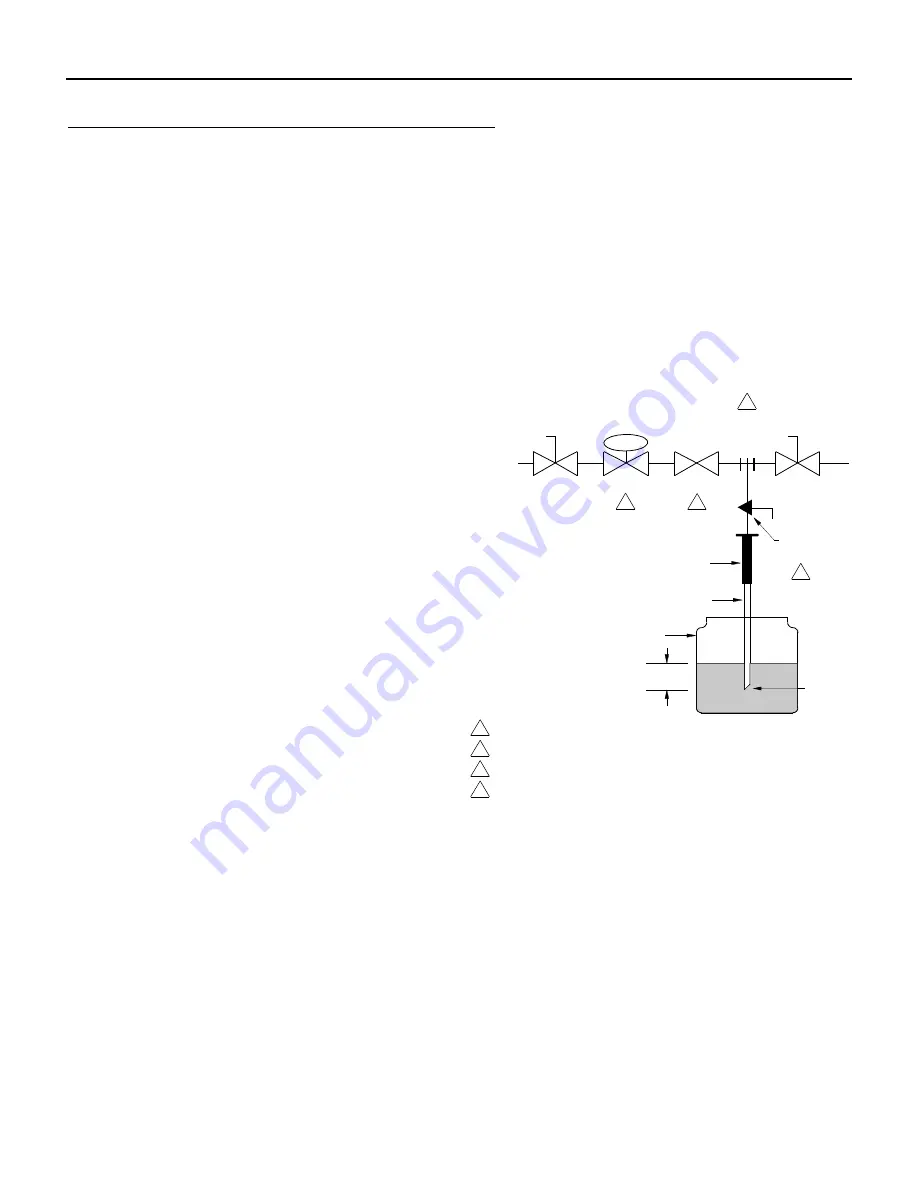

SAFETY SHUTOFF VALVE LEAK TEST:

Safety shutoff valves require a qualified technician to perform a leak (bubble) test to determine tightness

of closure on a least an annual basis. A very small amount of leakage is normal. Valve leakage rates

exceeding those noted in the table below require repair or valve replacement. For more detailed valve

leak test instructions, refer to the valve manufacturer’s instructions.

1.

De-energize the control system.

2.

Close the upstream manual gas valve.

3.

Connect a ¼” (6mm) tube to the outlet

pressure tap on the safety shutoff valve.

4.

Immerse the opposite end of the ¼” (6mm)

tube (cut to a 45° angle) vertically ½”

(13mm) into a clear container of water.

5.

Count the number of bubbles appearing

during a 10 second period.

6.

If the bubble rate is greater than that noted

in the table repair or replace the valve.

7.

If bubble rate is less than noted in the table,

remove the ¼” (6mm) tube, reconnect the

outlet pressure tap plug.

8.

Energize the control system and open

upstream manual gas valve.

9.

After testing check all piping connections

and plugs for external leakage.

The maximum leakage rate (bubbles/10sec.) is 6.

1/2 (13mm)

CUT AT

45 DEGREE

ANGLE

JAR OR GLASS WITH WATER

1/4 IN (6MM) ALUMINUM OR

COPPER PILOT TUBING

1/4 (6MM) FLEXIBLE TUBING

GAS SUPPLY

UPSTREAM

MANUAL

GAS COCK

PVR

SSOV

MANUAL

GAS COCK

DOWNSTREAM

TEST

TAP

LEAK

A

B

C

E

D

1

CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

2

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SSOV.

SSOV = SAFETY SHUTOFF VALVE.

4

3

Fig. 5 Valve Leak Test.

2

3

4

DOWNSTREAM

GAS COCK

MANUAL

1

F