A

RUVG

MANUAL

11 of 35

June 14

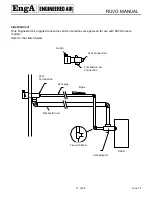

MOUNTING

Units

must

be

mounted

level.

Failure

to

do

so

can

cause

water

to

be

trapped

in

drain

pans

or

operational

problems

that

can

void

warranty.

Failure

to

do

so

can

result

in

injury

or

death,

damage

the

equipment

and/or

building

and

can

be

a

cause

of

poor

indoor

air

quality.

Equipment

must

be

installed

so

that

sufficient

working

clearance

and

component

access

is

provided.

Some

units

are

designed

for

cantilevered

installation.

Consult

the

Submittal

Record

for

specific

unit

mounting.

SHIPPING

MATERIALS

Remove

shipping

materials.

Shipping

materials

may

include,

but

are

not

limited

to:

•

Protective

covers

over

openings,

inlets,

condenser

coils

etc.

•

Protective

covers

over

split

sections

if

provided.

•

Tie

‐

down

bolts,

straps

and

blocks

on

fan

and

compressor

vibration

isolators.

•

Tie

‐

down

bolts,

straps

and

blocks

on

tilt

equipped

heat

pipes

and

enthalpy/desiccant

wheels

if

supplied.

•

Indirect

fired

heat

exchangers

may

be

supported

with

wood

for

shipping.

Remove.

PIPING,

ELECTRICAL

OR

CONTROL

SERVICE

CONNECTIONS

DO

NOT

install

anything

that

will

interfere

with

equipment

access

or

the

rating

plate.

Engineered

Air

equipment

is

constructed

with

cabinet

and

floors

designed

to

prevent

water

from

entering

the

building

through

the

installed

unit.

When

ordered,

factory

installed

pipe

chases

and/or

electrical

chases

are

built

into

the

unit

floor.

Factory

chases

are

provided

with

covers

that

need

to

be

replaced

and

sealed

after

piping

and

electrical

connections

are

made.

THE

FLOOR

OF

THE

UNIT

HAS

BEEN

MADE

WATER

‐

RESISTANT.

DO

NOT

CUT

OR

DRILL

HOLES

IN

THE

FLOOR

OR

USE

PENETRATING

FASTENERS.

All

penetrations

through

the

unit

walls

must

be

caulked

and

sealed

to

prevent

air

and/or

water

from

entering

the

unit.