A

RUVG

MANUAL

20 of 35

June 14

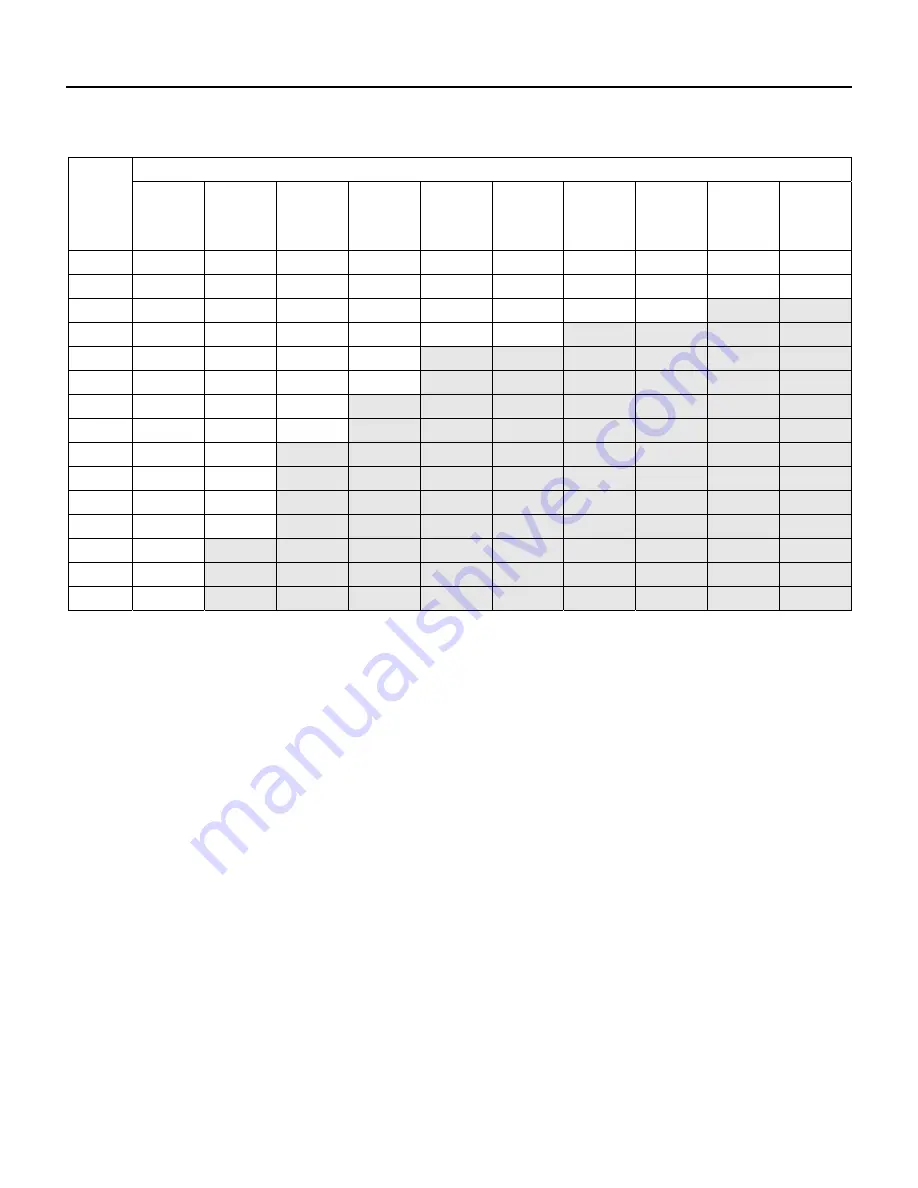

Recommended

24V

Field

Wiring

Size:

Copper

conductors

only

Circuit

Load

(Amps

)

(1)

Maximum

Total

Length

of

Run

<

50

Ft

<

100

Ft

<

150

Ft

<

200

Ft <

250

Ft <

300

Ft <

350

Ft <

400

Ft

<

450

Ft <

500

Ft

(~

15

m)

(~

30

m)

(~

45

m)

(~

60

m) (~

75

m) (~

90

m)

(~

105

m)

(~

120

m)

(~

135

m)

(~

150

m)

1

16

AWG

16

AWG

16

AWG

16

AWG 16

AWG 16

AWG 14

AWG 14

AWG

14

AWG 12

AWG

2

16

AWG

16

AWG

16

AWG

14

AWG 12

AWG 12

AWG 12

AWG 10

AWG

10

AWG 10

AWG

3

16

AWG

16

AWG

14

AWG

12

AWG 12

AWG 10

AWG 10

AWG 10

AWG

4

16

AWG

14

AWG

12

AWG

10

AWG 10

AWG 10

AWG

5

16

AWG

12

AWG

12

AWG

10

AWG

6

16

AWG

12

AWG

10

AWG

10

AWG

7

14

AWG

12

AWG

10

AWG

8

14

AWG

10

AWG

10

AWG

9

14

AWG

10

AWG

10

12

AWG

10

AWG

11

12

AWG

10

AWG

12

12

AWG

10

AWG

13

12

AWG

14

12

AWG

15

12

AWG

Notes:

1)

The

field

wiring

load

depends

on

the

actual

load

on

a

particular

control

circuit

the

field

wiring

is

connected

to.

Refer

to

the

internal

wiring

diagram

of

the

unit.

2)

The

table

above

is

based

on

a

maximum

10%

voltage

drop

on

a

24V

control

circuit.

Wire

size

was

calculated

using

the

following

formula:

CM

=

(25

x

I

x

L

)

/

V

Where

CM

is

circular

mils

of

conductor

for

a

constant

load

of

I

amps,

wire

length

L

in

feet

from

the

unit

to

the

field

device

and

back,

and

voltage

drop

V

.

When

connecting

to

a

three

phase

power

supply,

check

for

the

correct

rotation

of

all

motors

and

fans.

If

the

rotation

is

incorrect,

reverse

the

rotation

at

the

incoming

power

only.

All

electrical

conduit

outlets

in

the

control

panel

must

be

sealed

to

prevent

moist

building

air

from

migrating

to

the

control

panel.

All

penetrations

through

the

unit

walls

must

be

caulked

and

sealed

to

prevent

air

and/or

water

from

entering

the

unit.