A

RUVG

MANUAL

27 of 35

June 14

OPERATIONAL

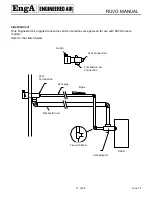

CHECK

FOR

GAS

FIRED

RUVG

UNITS

The

unit

has

been

tested

at

the

factory,

gas

consumption

clocked,

and

all

safety

controls

checked

to

ensure

they

operate.

Field

testing

will

confirm

all

components

are

operating

properly

after

shipping

and

installation.

1.

Read

all

of

this

section

before

proceeding.

It

may

be

necessary

to

refer

to

another

control

manual

to

perform

some

of

the

operation

test

procedure

and

then

return

to

this

document

to

complete

the

safety

checks.

2.

Purge

all

the

air

from

the

gas

lines.

Refer

to

the

Canadian

Natural

Gas

and

Propane

Installation

Code,

C.S.A.

Standard

B149.1

or

the

National

Fuel

Gas

Code

ANSI/Z223.1/NFPA

54

for

proper

method.

Check

all

connections

for

leaks

and

correct.

Ensure

that

the

inlet

pressure

agrees

with

the

approval

label.

3.

Adjust

airflow

through

the

unit

to

obtain

the

rating

plate

specified

airflow.

Operation

with

airflow

less

than

specified

can

damage

the

heat

exchanger.

4.

Do

not

re

‐

start

burner

when

the

heat

exchanger

is:

a.

very

hot

b.

full

of

gas

5.

Do

not

start

burner

unless

the

supply

fan

blower

access

door

is

secured

in

place

and

the

burner

access

cover

is

firmly

attached.

6.

Open

door

and

remove

access

panel

to

the

gas

heater

enclosure.

Note:

The

access

panel

must

be

in

place

except

when

servicing.

7.

Turn

the

gas

on

for

the

unit.

Check

for

leaking

gas

piping

to

the

unit

and

check

the

manifold

piping

up

to

the

safety

shutoff

valves.

8.

Check

the

main

and

safety

shut

off

valves

and

pilot

valve

for

leakage

following

the

valve

manufacture’s

recommendations.

9.

Move

gas

control

knob

to

“Off”

position.

10.

Install

a

tapped

fitting

for

attachment

to

a

manometer,

or

other

gauge

suitable

for

14.0”

w.c.,

in

the

inlet

pressure

tap,

and

for

10.0”

w.c.,

in

the

manifold

pressure

tap.

11.

Wait

5

minutes

for

any

gas

to

clear

out.

If

you

smell

gas,

see

Step

4

above

and

correct

leak.

If

you

don’t

smell

gas

or

have

corrected

any

leaks,

go

to

the

next

step.

12.

Turn

gas

control

knob

to

“On”

position