XF

Rev: 7, 2008-10-14

Page 15

Fasten the installation template sticker exactly over the centre line and cross

line.

(The propeller may be mounted slightly offset)

The bow thruster may be mounted at any angle, from 0° - 90°. Installation

from 45° to horizontal requires a support for the motor.

WARNING:

The motor has to be properly supported to offload weight and

tension on tunnel / transom

.

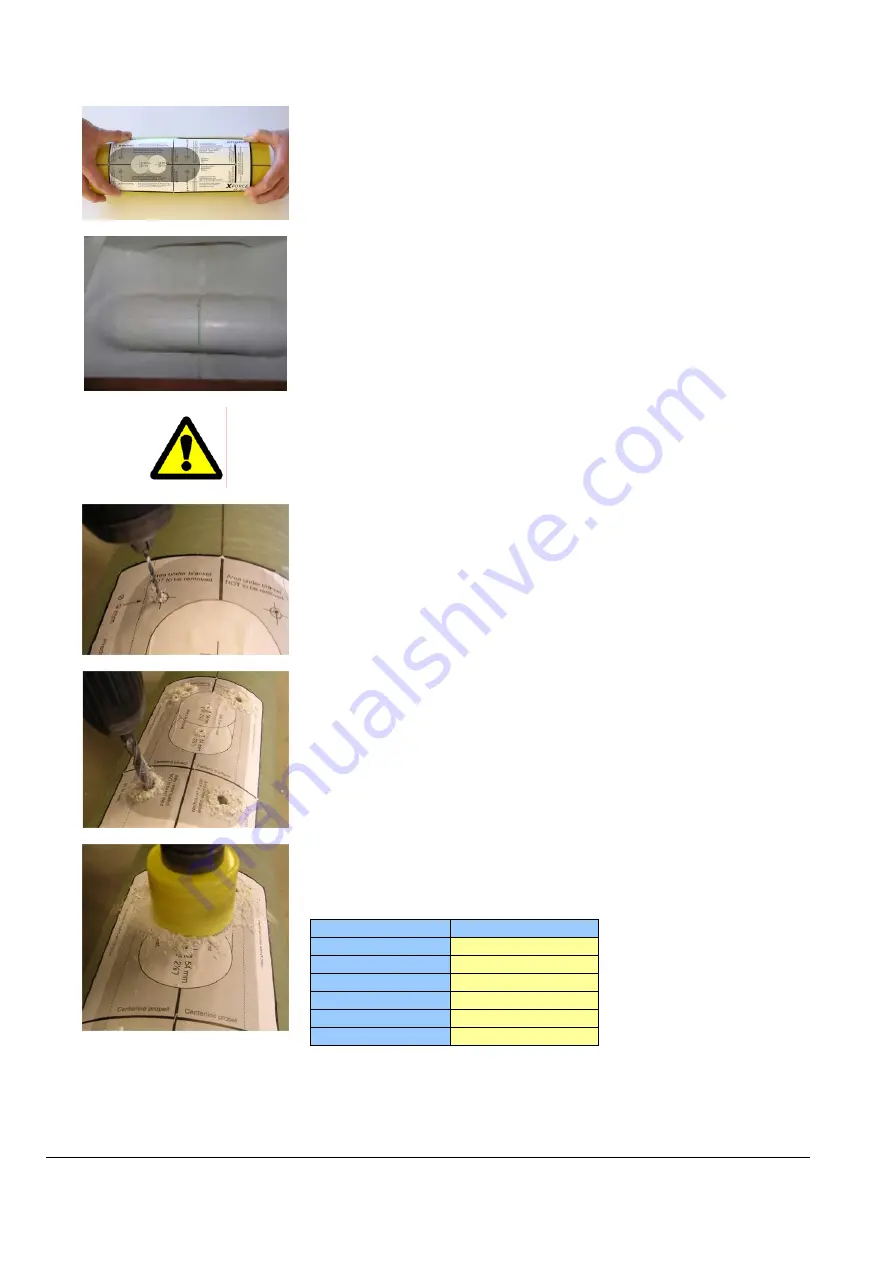

6.1.3 Pre-drill

All marked holes must be pre-drilled Ø 2.0 mm

(1/16”)

Use a centre punch prior to drilling.

6.1.4

Drilling holes for the bracket bolts

The 4 bracket holes must be drilled Ø 9 mm

(11/32”)

6.1.5

Drilling the insertion hole

Use a saw drill designed for glass fibre cutting, with the correct size according

to the thruster model to be fitted. Slow speed is recommended.

Thruster model

Saw drill (Ø)

XForce 20

Ø 35 mm

(1

⅜

”)

XForce 40

Ø 54 mm

(2

⅛

”)

XForce 60

Ø 54 mm

(2

⅛

”)

XForce 75

Ø 67 mm

(2

⅝

”)

XForce 90

Ø 67 mm

(2

⅝

”)

XForce 130

Ø 83 mm

(3 ¼”)

Summary of Contents for XForce Series

Page 24: ...XF Rev 5 2008 10 06 Side 24 6 11 Elektriske kobling skjemaer 6 11 1 XForce 20 ...

Page 25: ...XF Rev 5 2008 10 06 Side 25 6 11 2 XForce 40 60 75 90 130 ...

Page 32: ......

Page 56: ...XF Rev 7 2008 10 14 Page 24 7 10 Wiring diagrams 7 10 1 XForce 20 ...

Page 57: ...XF Rev 7 2008 10 14 Page 25 7 10 2 XForce 40 60 75 90 130 ...

Page 64: ......