5 Operation

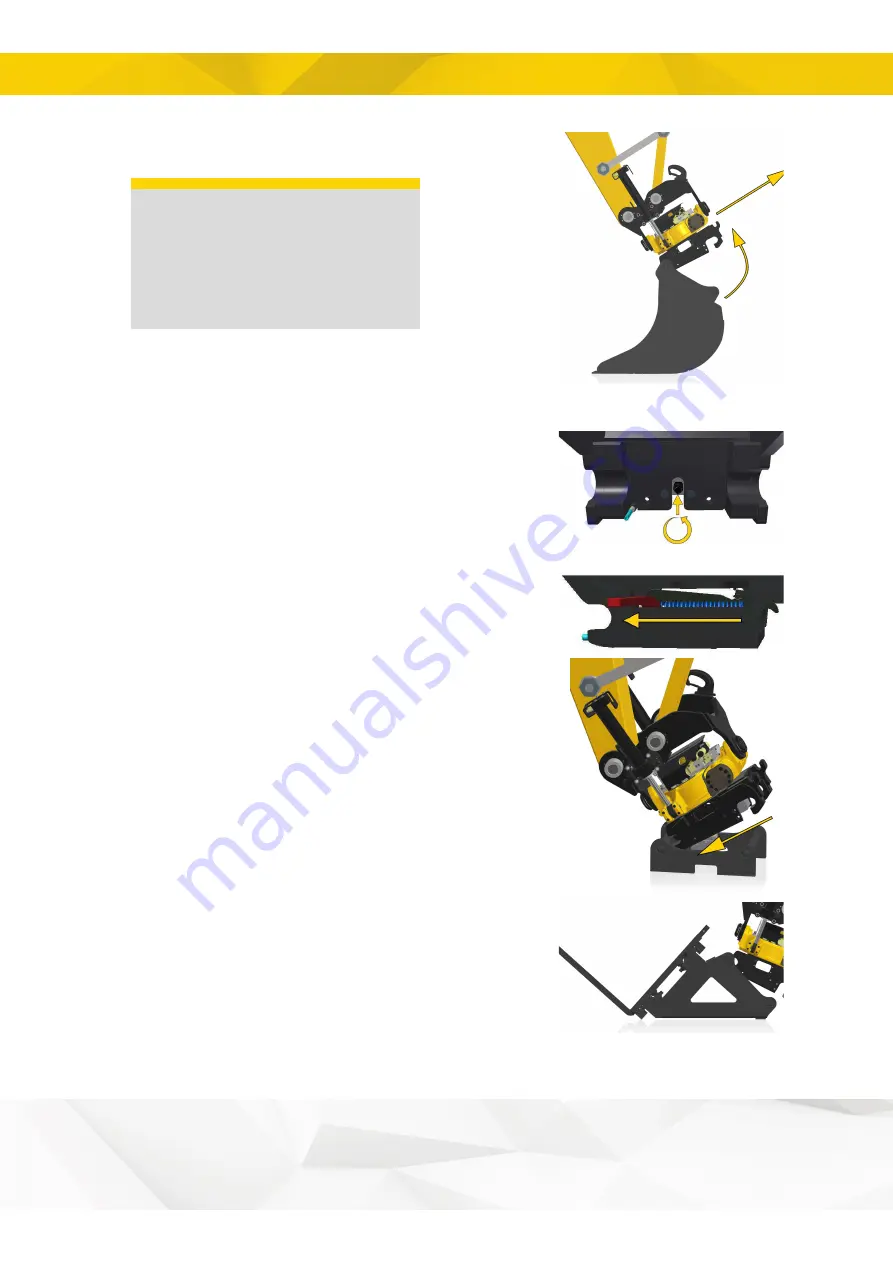

5. The locking bolts are now in the open position and the

tool is free. Carefully raise the tiltrotator from the tool.

IMPORTANT

The machine may only be

operated with the quick hitch

lock switch in the activated

position when connecting and

disconnecting tools.

5.9.3. Connecting the tool, mechanical

lock

1. Open the quick hitch lock with a suitable tool

On models with a screw, turn it anti-clockwise until

the locking bolts engage and the indicator rod is in its

outermost position.

On models with a lever, use an extension pipe and move

the lever to its end position. The Indicator rod will then be

in its outermost position and the lock clamp will keep the

locking bolts open.

2. Move the quick hitch towards the tool.

To avoid overloading when connecting the pallet forks,

the quick hitch locking pins must be turned away from the

forklift tines.

30