6 Maintenance

3. See Table 1. and Table 2. before tightening the pins. Measure the pins or check the

delivery note to ascertain fastener thread sizes. Tighten the expander pins alternately to

the recommended torque to achieve even installation.

The sleeve must always protrude to ensure expansion. The washer (or fastener, for

variants without washers) must never come into contact with the end of the shaft body

or attachment lug. Should this occur, go to section 6.3.2.2. Removal and follow the

instructions under step 2. If the washer on either side comes into contact with the

attachment point lug or the end of the shaft body, the sleeve is the wrong size. The

expander pins must then be fitted with oversize sleeves.

4. Grease the joint with 3-5% molybdenum sulfide grease before putting the machine into

operation. Regular greasing extends the service life of the expander pins.

5. Start the base machine and move the joint back and forth. Retighten to the

recommended torque. This process makes sure the sleeves bed in.

6.4. Lubricate every 16 operating hours

engcon recommends greasing at 16 hour intervals. See chapter 6.4.1. Lubrication, stone

and sorting grab.

When working in water, the lubrication interval is reduced to 8 hours.

If your product is equipped with a rotator, there are instructions for the

rotator section in the tiltrotator user manual.

Grease recommendation:

On delivery, we fill your product with our recommended universal mineral oil-based grease

with an EP additive, a lithium soap thickener and a hardness of (NLGI) 2. In severe cold

we recommend hardness (NLGI) 1.

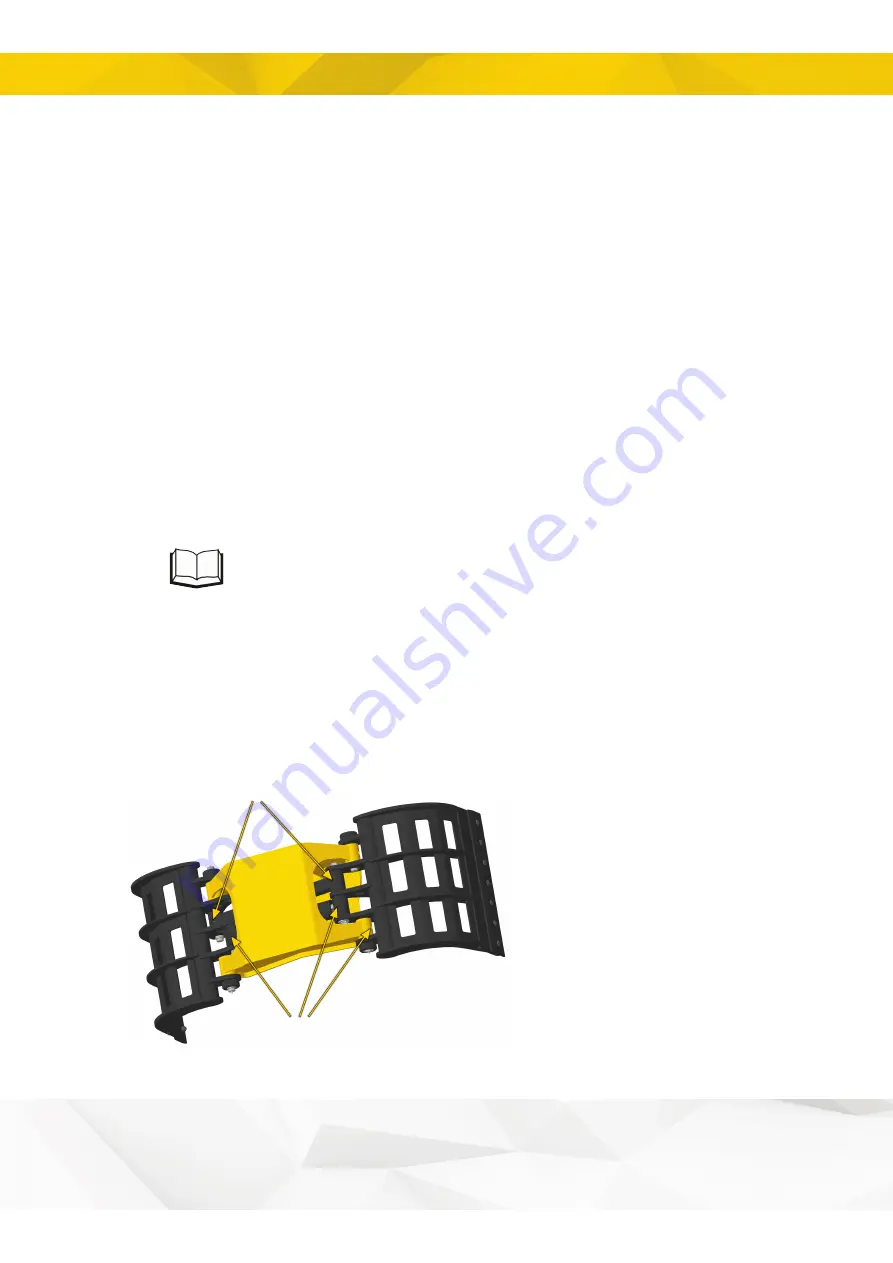

6.4.1. Lubrication, stone and sorting grab

The arrows show the location of the grease nipples.

Grease quantity: 3-4 pump strokes per nipple.

20

Summary of Contents for SK02

Page 27: ...Notes...