Page | 45

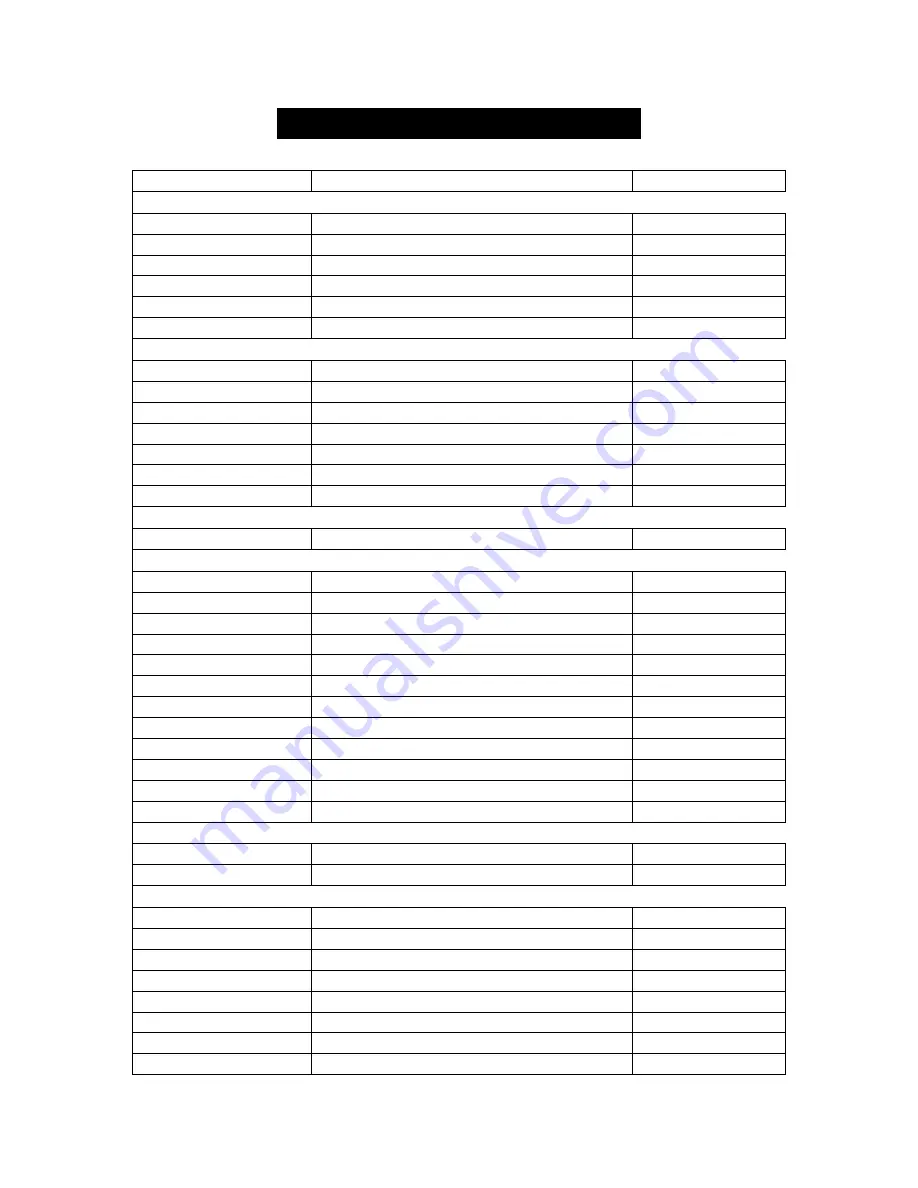

REPLACEMENT PARTS LIST

Part

Number

Part

Description

Diagram

#

Gaskets

AC

‐

HLG

Hopper

Lid

Gasket

1

AC

‐

DGKEP

Door

Gasket

2

AC

‐

GGK

Three

Piece

Window

Gasket

Kit

3

PU

‐

CBG

Exhaust

Blower

Gasket

4

AC

‐

GGK

Ash

Pan

Gasket

5

PU

‐

CGEP

Cradle

Mating

Gasket

6

Electrical

Components

PU

‐

CHA

Igniter

Cartridge

Heater

7

PU

‐

076002B

Exhaust

Blower

8

PU

‐

4C442

Room

Air

Blower

9

AC

‐

HLS

Hopper

Lid

Switch

10

CU

‐

VS

.05"

of

WC

Vacuum

Switch

11

CU

‐

047042

2

RPM

Auger

Motor

12

PU

‐

CBEP

Control

Board

13

Cast

Iron

CA

‐

AMPP

Cast

Iron

Auger

Motor

Collar

14

Steel

CA

‐

AC

Steel

Auger

Coupler

15

IP

‐

25EP

Firebox

Baffle

16

PU

‐

ECCEP

Exhaust

Cleanout

Covers

17

PU

‐

BPCEP

Cradle

18

PU

‐

BPEP

Burnpot

19

CA

‐

40

Steel

Door

20

PU

‐

AFEP

Steel

Auger

21

AC

‐

GSEP

Glass

Support

Brackets

22

PU

‐

SKEP

Insert

Surround

Kit

23

PU

‐

SPSEP

Insert

Side

Panel

Set

24

PU

‐

ITEP

Insert

Top

and

Rear

Cover

Plate

25

PU

‐

APEP

Ash

Pan

26

Glass

AC

‐

G40

Three

Piece

Glass

‐

Center

27

AC

‐

G41

Three

Piece

Glass

‐

Side

28

Misc

CU

‐

RG

Rubber

Auger

Motor

Bushing

29

AC

‐

CFBEP

Fiberboard

30

AC

‐

LSEP

Log

Set

Not

Shown

PU

‐

VH

High

Temp.

Vacuum

Hose

Not

Shown

PU

‐

62

‐

40

‐

151

‐

3

Hopper

Lid

Latch

31

AC

‐

SHN

Nickel

Spring

Handle

Not

Shown

AC

‐

SH

Brass

Spring

Handle

Not

Shown

PU

‐

EDIC

Exhaust

Tube

Insulation

Wrap

Not

Shown