CCS3100

13

User Manual R0.2

Fault Definition:

Indicates that the value read by the screw pressure sensor is above the value entered to the "P008

Screw Pressure Alarm" parameter. It is a malfunction that stops the compressor rapidly.

Possible Causes and required actions:

Make sure that the relevant parameter is suitable for your application.

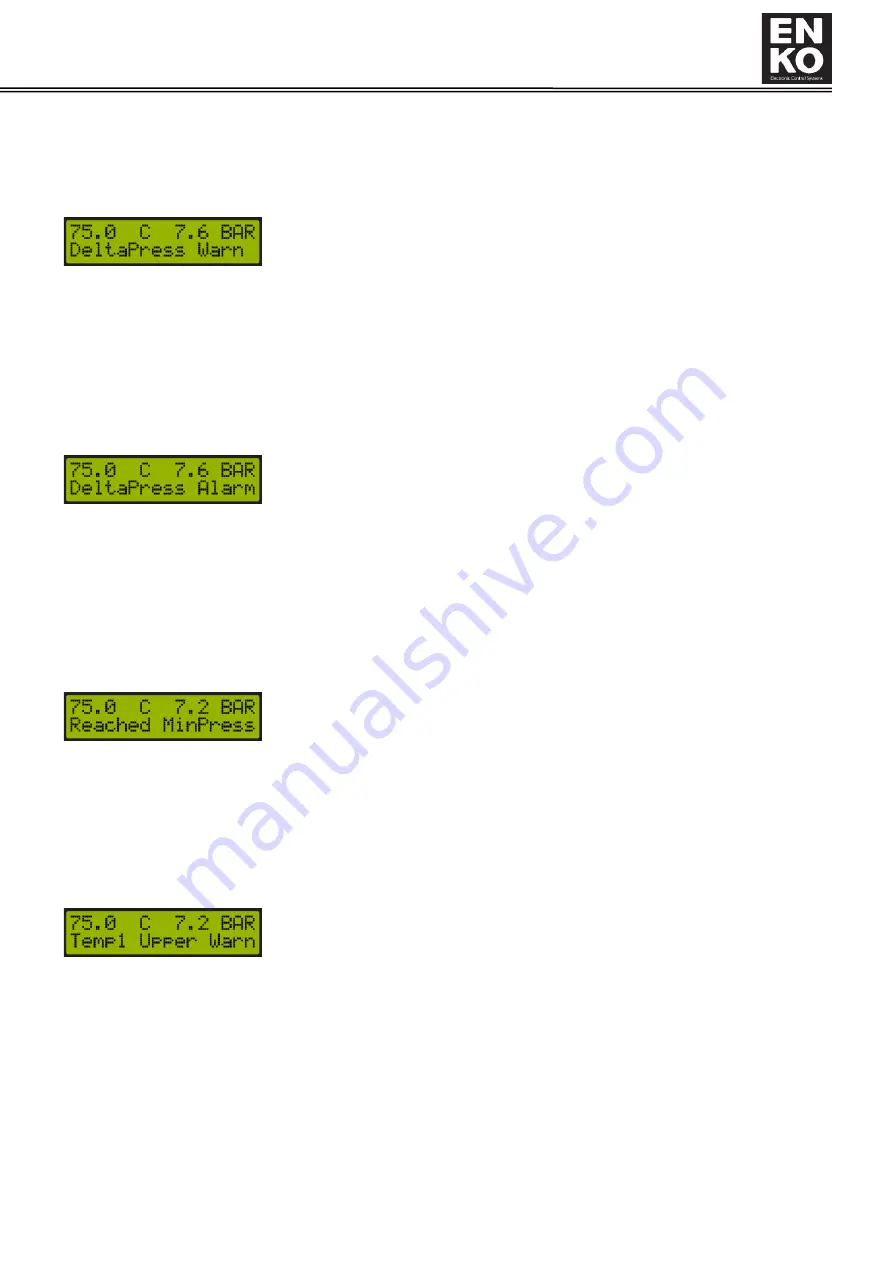

Pressure Difference Warning (Delta Press Warn)

Warning Definition:

After the value read by the screw pressure sensor exceeds the value entered to the "P013

Sufficiency Pressure" parameter, it indicates that the value difference between the line pressure and the screw

pressure exceeded the value entered to the "P012 Delta Pressure Warning" parameter. It is just a warning message.

Does not stop the motor.

Possible Causes and required actions:

Make sure that the relevant parameter is suitable for your application. There

may be an air leakage in the system.

Pressure Difference Fault (DeltaPress Alarm)

Fault Definition:

After the value read by the screw pressure sensor exceeds the value entered to the "P013

Qualification Pressure" parameter, it indicates that the value difference between the line pressure and the screw

pressure exceeded the value entered to the "P011 Pressure Difference Error" parameter. It is a malfunction that

stops the compressor rapidly.

Possible Causes and required actions:

Make sure that the relevant parameter is suitable for your application. There

may be an air leakage in the system.

Minimum Pressure Reached (Reached MinPress)

Fault Definition:

It is a fault that occurs when the screw pressure measured while the compressor is running does

not reach the value entered to the "P013 Sufficiency Pressure" parameter during the time entered to the "P038

Sufficiency Delay" parameter and stops the compressor rapidly.

Possible Causes and required actions:

Make sure that the relevant parameter is suitable for your application. There

may be an air leakage in the system.

Screw Temperature High Warning (Temp1 Upper Warn)

Warning Definition:

Indicates that the value read by the Screw temperature sensor connected to terminals 7-8,

which are defined as AN2, is higher than the value entered to the "P123 Temperature 1 High Warning" parameter. It

is just a warning message. Does not stop the motor.

Possible Causes and required actions:

There may be a problem that causes the temperature to increase. Incorrect

sensor may have been selected. Incorrect sensor type may have been selected. The value that is entered to the

parameter may have been wrong for the application.