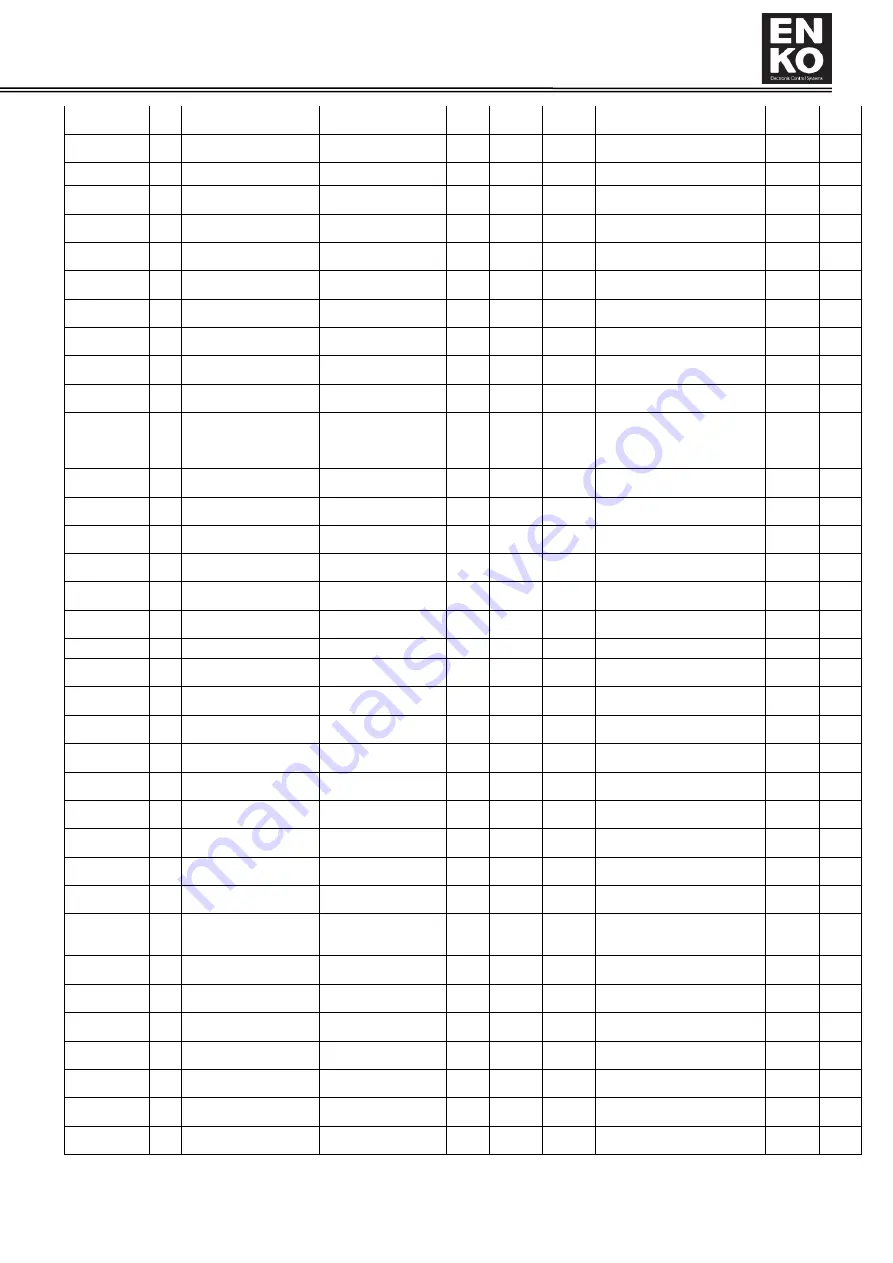

CCS3100

22

User Manual R0.2

Output

87

Delay

Output-4 Function

Delay Time

0

30

0

sec

2

Output

88

Contactor

Output-4 Contact

Polarity

0

1

0

0: NO 1: NC

2

Output

90

Function

Output-5 Function

0

28

1

1: Main Contactor

2

Output

91

Delay

Output-5 Function

Delay Time

0

30

0

sec

2

Output

92

Contactor

Output-5 Contact

Polarity

0

1

0

0: NO 1: NC

2

Maintenance

98

General Maint.

Overall Maintenance

Time Set

200

30000

2500

h

3

Maintenance

99

Roller Maint.

Bearing Maintenance

Time Set

200

30000

20000

h

3

Maintenance 100 OilChange Maint.

Oil Change Service

Time Set

200

30000

5000

h

3

Maintenance 101 AirFilter Maint.

Air Filter Service

Time Set

200

30000

5000

h

3

Maintenance 102 OilFilter Maint.

Oil Filter Service

Time Set

200

30000

2500

h

3

Maintenance 103 SepFilter Maint.

Seperator Filter

Service Time Set

200

30000

5000

h

3

Maintenance 107

Maintaince Reset

Maintenance Time

Reset

0

6

0

0: None 1: General 2: Roller

3: OilChange

4: Air Filter. 5: Oil Filter 6:

Seperator Filter

2

Temperature 122 Temp1 High Alarm

Temperature-1 High-

Fail Alarm

-

200,0

200,0

100,0

C

1

Temperature 123 Temp1 High Warn

Temperature-1 High-

Warning Alarm

-

200,0

200,0

90,0

C

1

Temperature 124 Temp1 Low Alarm

Temperature-1 Low-

Fail Alarm

-

200,0

200,0

-20,0

C

1

Temperature 125 Temp1 Low Warn

Temperature-1 Low-

Warning Alarm

-

200,0

200,0

-10,0

C

1

Temperature 126 Preheat Limit

Preheat Temperature

Limit

-

200,0

200,0

10,0

C

1

Temperature

127

Temp1 SensorType

Temperature-1

Sensor Type Select

0

4

0

0: NTC 1: KTY81

2

Temperature 128 Temperature Unit

Temperature Unit

0

1

0

0: Degree 1:Fahrenayt

1

Temperature 129 Fan Start

Fan Start

Temperature Level

-

200,0

200,0

80,0

C

1

Temperature 130 Fan Stop

Fan Stop

Temperature Level

-

200,0

200,0

60,0

C

1

Temperature 131 Dryer Start

Dryer Start

Temperature Level

-

200,0

200,0

15,0

C

1

Temperature 132 Dryer Stop

Dryer Stop

Temperature Level

-

200,0

200,0

5,0

C

1

Temperature 134 Temp2 High Alarm

Temperature-2 High-

Fail Alarm

-

200,0

200,0

100,0

C

1

Temperature 135 Temp2 High Warn

Temperature-2 High-

Warning Alarm

-

200,0

200,0

90,0

C

1

Temperature 136 Temp2 Low Alarm

Temperature-2 Low-

Fail Alarm

-

200,0

200,0

-20,0

C

1

Temperature 137 Temp2 Low Warn

Temperature-2 Low-

Warning Alarm

-

200,0

200,0

-10,0

C

1

Temperature

138

Temp2 SensorType

Temperature-2

Sensor Type Select

0

4

0

0: NTC 1: KTY81

2

Temperature

139

Temp2 SensorMode

Temperature-2

Sensor Operation

Mode

0

2

0

0: Off 1: Normal 2: Difference

2

Temperature 140 Press Comp.Temp.

-

200,0

200,0

0,0

C

2

Temperature 141 Oil Freeze Prvnt

Oil Freeze Prevention

Temperature

-

200,0

10,0

-99,9

C

2

Mains

142 Unbalance

Mains Feed

Unbalance Value

0

100

20

2

Mains

143 Volt Low Alarm

Mains Feed Low-

Voltage Fail

0

600

310

V

2

Mains

144 Volt Low Warn

Mains Feed Low-

Voltage Warning

0

600

330

V

1

Mains

145 Volt High Alarm

Mains Feed High-

Voltage Fail

0

600

466

V

2

Mains

146 Volt High Warn

Mains Feed High-

Voltage Warning

0

600

450

V

1