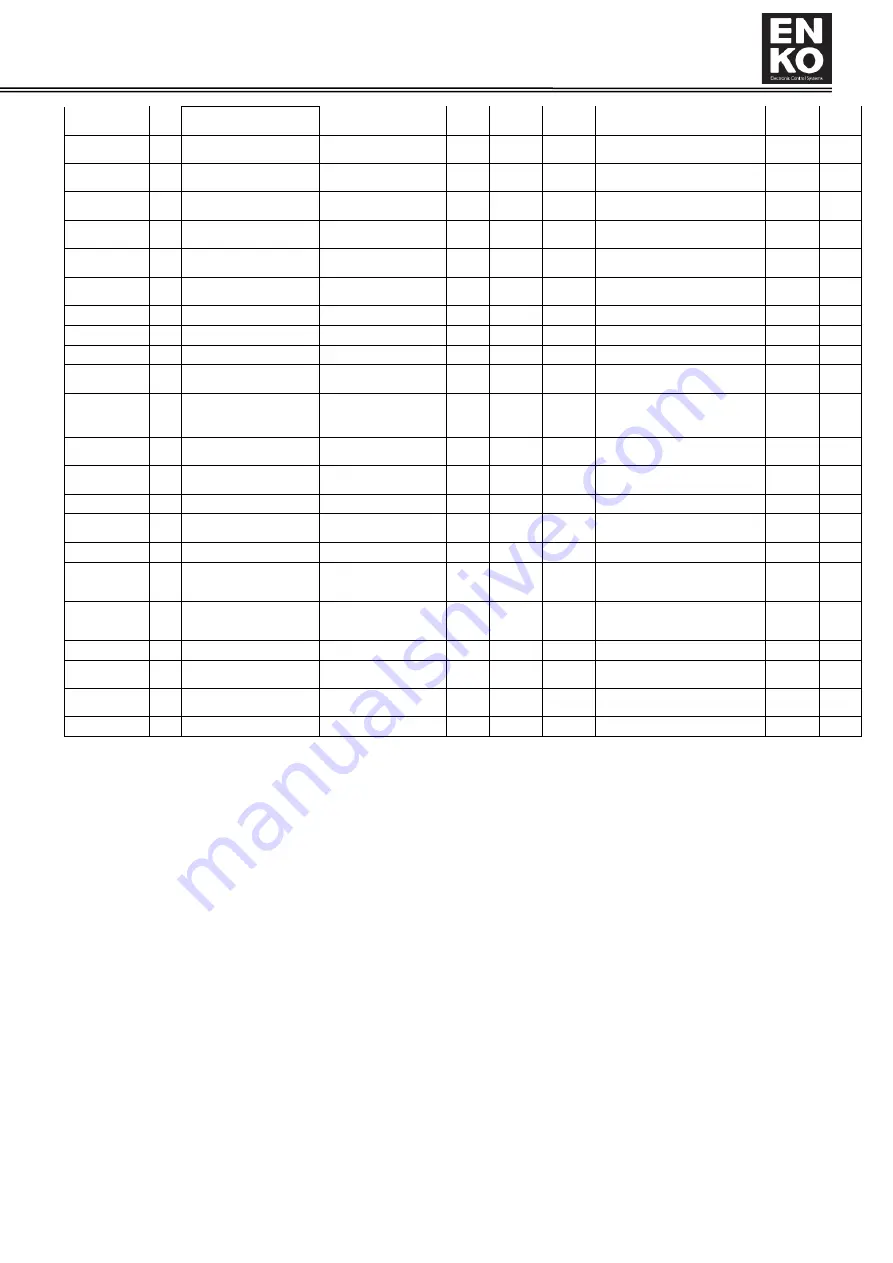

CCS3100

23

User Manual R0.2

Mains

147 Freq Low Alarm

Mains Feed Low-

Frequency Fail

0,0

80,0

45,0

Hz

2

Mains

148 Freq Low Warn

Mains Feed Low-

Frequency Warning

0,0

80,0

47,0

Hz

1

Mains

149 Freq High Alarm

Mains Feed High-

Frequency Fail

0,0

80,0

55,0

Hz

2

Mains

150 Freq High Warn

Mains Feed High-

Frequency Warning

0,0

80,0

53,0

Hz

1

Mains

151

Connection Type

Mains Input Wiring

Type

0

2

2

0:(1Phase) 1:(

Notr) 2:(3Phase)

3

Mains

152

PhaseSeq Protect

Mains Feed Phase

Sequence Protection

0

1

1

0: Passive 1: Active

2

Mains

153

Mains Faults

Mains Feed Failure

Control

0

1

0

0: Passive 1: Active

2

General Set.

154 Factory Password

3

General Set.

155 Service Password

2

General Set.

156 User Password

1

General Set.

158 Maximum Startup

Maximum Start

Actions Per Hour

2

9999

10

1

General Set.

159

Start Source

Compressor Start

Signal Input Type

0

4

0

0: Panel-DI-Modbus 1: Panel

2: Digital Input 3: ModbusRTU

4: Digital Input-ModbusRTU

1

General Set.

160

Working Mode

Compressor

Operation Mode

0

1

1

0: Manual 1: Automatic

1

General Set.

161

Idle Time S/D

Idle Time Operation

S/D

0

1

0

0: Passive 1: Active

1

General Set.

162 Horn Mode

Horn Operation Mode

0

1

0

0: Continuous 1: Pulse

1

General Set.

163

PressLose Preve.

Pressure-Loss

Prevention

0

2

0

0: Passive 1: Step 2: Slope

2

General Set.

164 Parameter Save

Parameter Saving

0

2

0

0: No 1: Save 2: Use

1

General Set.

166

Language

Language Selection

0

2

0

0: Turkish 1: English

2: User Defined

1

General Set.

167

Return Factory

Factory Settings

0

2

0

0: No 1: Factory Value

2: User Defined

3

General Set.

168 ClearFaultRecord

Alarm History Reset

0

1

0

0: No 1: Yes

3

General Set.

169

Motor Time Clear

Motor Operation Time

Reset

0

1

0

0: No 1: Yes

3

General Set.

170 Menu Logout Time

Menu Timeout

Duration

1

30

3

min

1

General Set.

171 Menu Logout

Menu Log Out

0

1

0

0: No 1: Yes

2

2.2. Parameter descriptions

2.2.1 Pressure Parameters

All parameters related to pressure are under this heading.

P002: Idle Pressure (Idle Pressure):

When the line pressure reaches/exceeds the value specified with this parameter while the device is running at load,

the device switches to idle operation.

P003: Load Pressure (Onload Pressure):

In automatic operation mode, if the line pressure reaches or drops below the value specified with this parameter

while the compressor is in stop or idle mode, the device will start to run and switch to load.

P004: Discharge Pressure Alarm Level (Line Alarm Value):

When the supply pressure reaches the value specified here, the device switches to fault mode at the end of the time

entered to the "P033 Line Pressure Alarm Delay" parameter. The protection function can be cancelled by setting the

related parameter to "0".