CD-1300-ST

ENMET

Manual Revision Date – June 15, 2017

P a g e

|

3

Manual Part No. – 80003-134

2.0 Features

2.1 Display and Indicators

The basic

CD-1300-ST Series

has a single green LED on the front panel which illuminates whenever the unit is operating. This

LED is on steadily when the measured concentration is below the high CO

2

limit, and blinks whenever the concentration is above

the limit.

The standard factory high limit is 1000 ppm, but can be easily adjusted in the field. The procedure for adjusting the high CO

2

limit

is described in Section 5.2.

The display option adds a 4-digit liquid crystal display (LCD) to the front panel. The display shows the measured CO

2

concentration in parts per million (ppm). 1000 parts per million equals 0.1%.

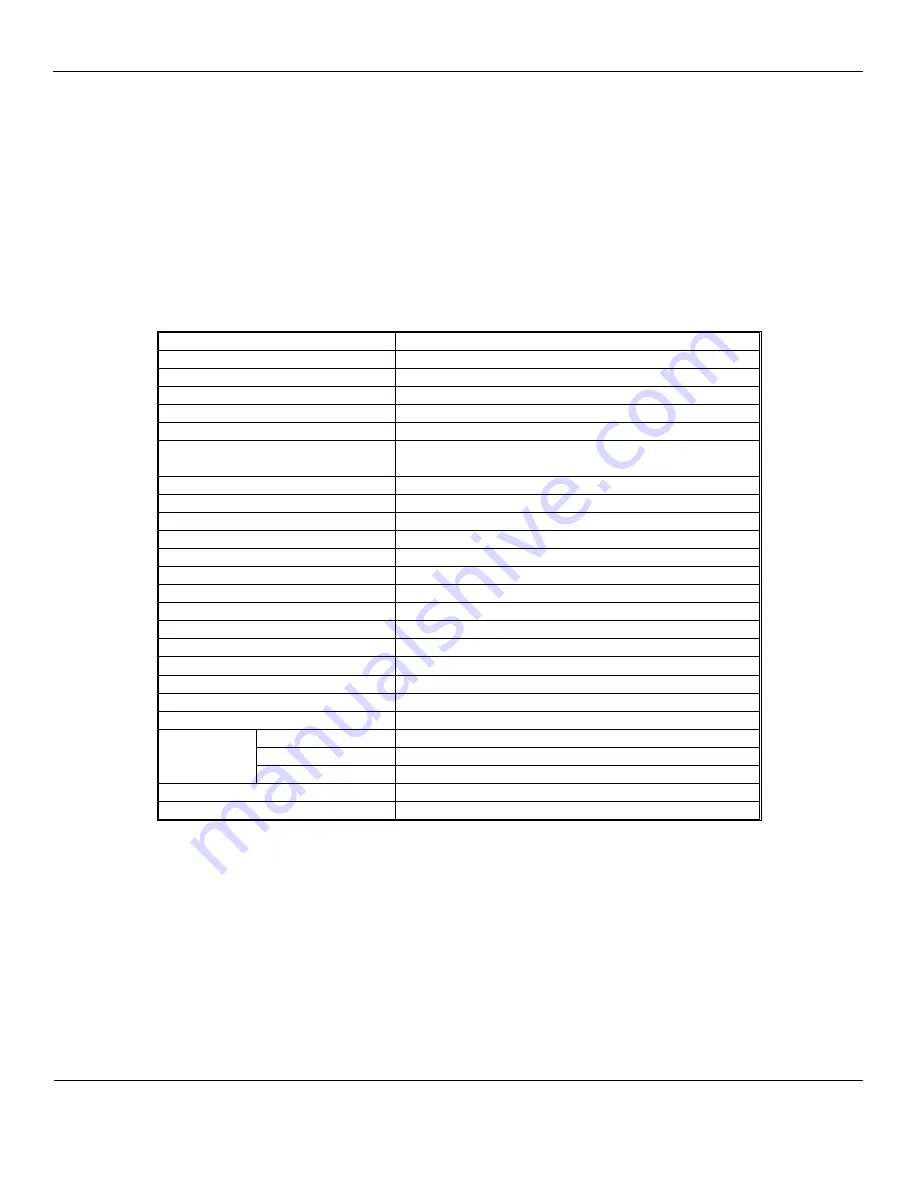

2.2 Specifications

Operating principle

Non-dispersive infrared (NDIR)

Gas sampling method

Diffusion or sample draw

Measurement range

0 – 2000 ppm CO

2

, Optional 0 – 5000 ppm

Typical drift (per year)

±75 ppm (@ 1200ppm)

Accuracy

±5% of reading or ±75 ppm, whichever is greater

Repeatability

±20 ppm

Recommended Calibration

Interval

One Year

Response time

Less than 1 minute

Operating temperature range

0 to 50

C

Operating humidity range

0 - 90% RH (non-condensing)

Storage temperature

-30 to + 60

C

Power requirements

20 – 28 V

RMS

AC, 18 - 30 V

DC

Power consumption

Less than 2W @ 24 V

AC

Calibration adjustments

Span only (offset electronically nulled)

Calibration verification time

10 minutes typical

Dimensions

5.2" x 3.2" x 1.4"

Voltage output (linear)

0 – 10 volts DC standard

Current output (linear)

4 - 20 mA (R

L

50

Ω

)

Warm-up time

3 minutes

Weight

6.5 Oz. (0.35 Kg)

Optional Digital Display

4 digit, .35" LCD

Optional

High Limit

Contact

set point range

0 to full scale

contact polarity

jumper selectable

contact rating

2A @ 24 V

AC

Operating life expectancy

10 years typical

Warranty

12 months, parts and labor through repair or exchange

N

OTE

:

All specifications stated in this manual may change without notice.