CO-Guard

ENMET

Manual Release Date – June 8, 2017

P a g e

| 11

Manual Part No. – 80002-044

5.0 Maintenance

The

CO-G

UARD

maintenance menus that are accessed by pressing the

M

ENU

button and entering a valid access code. The access

code is set at the factory and may be changed by following the access code menu explained in section 5.5.

5.1 Maintenance Menus

C

AUTION

:

Do Not Attempt a Span Procedure Without Calibration Gas Applied to The Sensor

; if this is done, the instrument is

forced into a calibration fault mode.

Pushbutton switches control the

M

ENU

and

S

ELECT

functions. The

M

ENU

and

S

ELECT

button locations are indicated on the

display panel, see

Figure 3.

The

M

ENU

button is used to display the various menu options and make incremental changes to

numbers such as alarm points, calibrations gas, etc. The

S

ELECT

button is used to select that option, set zero or span digit.

To enter the maintenance menu, press and hold the

M

ENU

button for 2 to 4 seconds

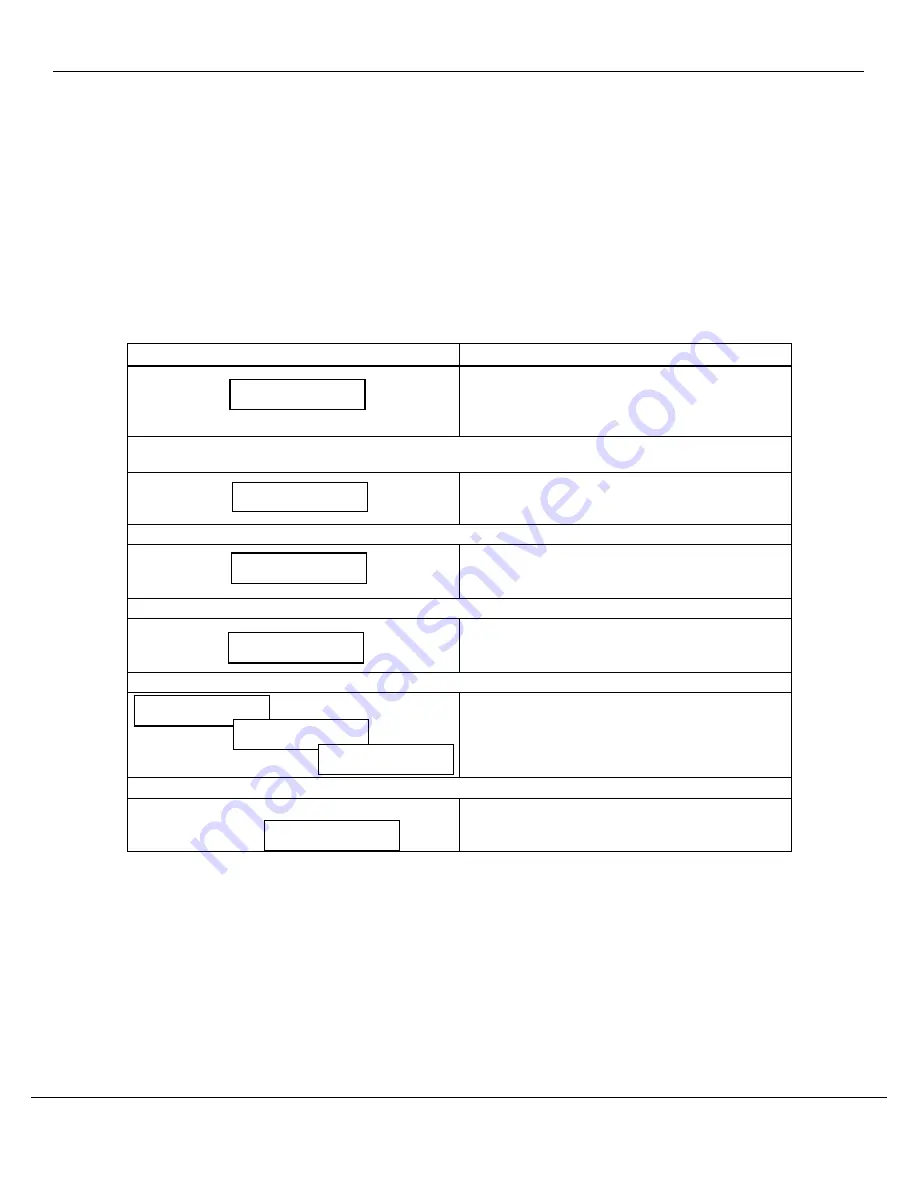

Table 3

indicates the maintenance menu sequence see

Figure 6

for a detailed maintenance menu flow chart.

Table 3: CO-G

UARD

Maintenance Menus Sequence

Example of Display

Function

Normal Display Mode

Measurement of CO

Press and

hold

the

M

ENU

button for 2 – 4 seconds to enter the Maintenance Menu

The Power/Fault LED will flash Green – Red to indicate the

CO-G

UARD

is in Maintenance Mode

To exit the maintenance Menu and return to the

Normal Display Mode:

If intended function Press

S

ELECT

button

Press the

M

ENU

button to advance to the Zero procedure

For adjusting Zero:

If intended function Press

S

ELECT

button

Press the

M

ENU

button to advance to the Span procedure

For adjusting the Span:

If intended function Press

S

ELECT

button

Press the

M

ENU

button to advance to each Alarm set point procedures

For adjusting the Alarm 1, 2 and 3 set points:

If Intended Function Press

S

ELECT

button

Press the

M

ENU

button to advance the mA Span set point procedure

For adjusting the mA Span set point:

If intended function Press

S

ELECT

button

Pressing the

M

ENU

button without pressing the

S

ELECT

button will allow you to cycle through the menu options.

You must Press the

S

ELECT

button to initiate the desired operation.

5ppm

Exit

Zero

Span

mA Span

Alarm1

Alarm2

Alarm3