EX-5100 C

OMBUSTIBLE

ENMET

11

5.2.1 Zero Adjust

A ZERO function should be performed only when the

EX-5100

sensor/transmitter is exposed to fresh air. If the air at the

sensor is in question, use a cylinder of 20.9% oxygen to provide a clean air reference. Attach the gas cylinder to the regulator

and regulator to the calibration cover, allow gas to flow over the sensor for 3-5 minutes.

Enter the maintenance menu by placing the magnet over the

M

ENU

switch for 2 to 4 seconds. See Figure 5,

EX-5100

Maintenance Menu flow chart.

The first menu available is the Zero.

Tap the

S

ELECT

switch to perform a Zero.

If the Zero is successful: Cal OK appears and in 1 – 2 seconds display will change to Span.

If you wish to Span the sensor, Tap the

S

ELECT

switch. You are now ready to apply gas. Proceed to gas span step 2.

If you wish to Exit the maintenance menu, Tap the

M

ENU

switch until Exit is displayed, then Tap the

S

ELECT

switch to return

to the instrument to Normal Gas Display.

If the Zero is Not successful: the sensor is outside of safe parameters to be zeroed, the display will read Bad Zero.

Repeat section 5.2.1 Zero Adjust making sure to use a cylinder of 20.9% Oxygen.

5.2.2 Gas Span

It is recommended that the Zero Function be performed first.

Enter the maintenance menu. See Figure 5,

EX-5100

Maintenance Menu flow chart.

1.

Tap the

M

ENU

switch once to display Span on the screen.

2.

Tap the

S

ELECT

switch to perform a Span procedure. The display will alternate between the calibration gas concentration

and a signal level.

3.

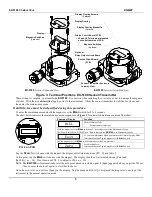

Attach the associated calibration gas cylinder to the regulator and calibration cover. See to Figure 3.

4.

Open the valve to apply the calibration gas to the sensor.

5.

Watch for the signal level to stabilize. Refer to Table 4 for typical response times.

6.

Once the signal level has stabilized, the

EX-5100

will automatically lock in the calibration data and:

If the Span is successful, Cal OK appears on the display momentarily, then advances to Alarm 1. Remove calibration gas.

To exit maintenance menu tap the

M

ENU

switch until Exit appears, then tap the

S

ELECT

switch.

If the sensor is outside of acceptable parameters, Bad Span is displayed momentarily, then returns to Span.

Remove calibration gas. Tap the

M

ENU

switch until Exit appears, then tap the

S

ELECT

switch. Check span gas and

repeat calibration in 30 – 60 minutes.

If the sensor did not respond to gas, Same mV is displayed momentarily, then returns to Span.

Remove calibration gas, tap the

M

ENU

switch until Exit appears, then tap the

S

ELECT

switch and try calibration

again in 30-60 minutes.

If the sensor will not calibrate See Section 5.4.

N

OTE

:

Some software revisions require the

S

ELECT

switch be tapped to accept the signal.

7.

Calibration is complete.

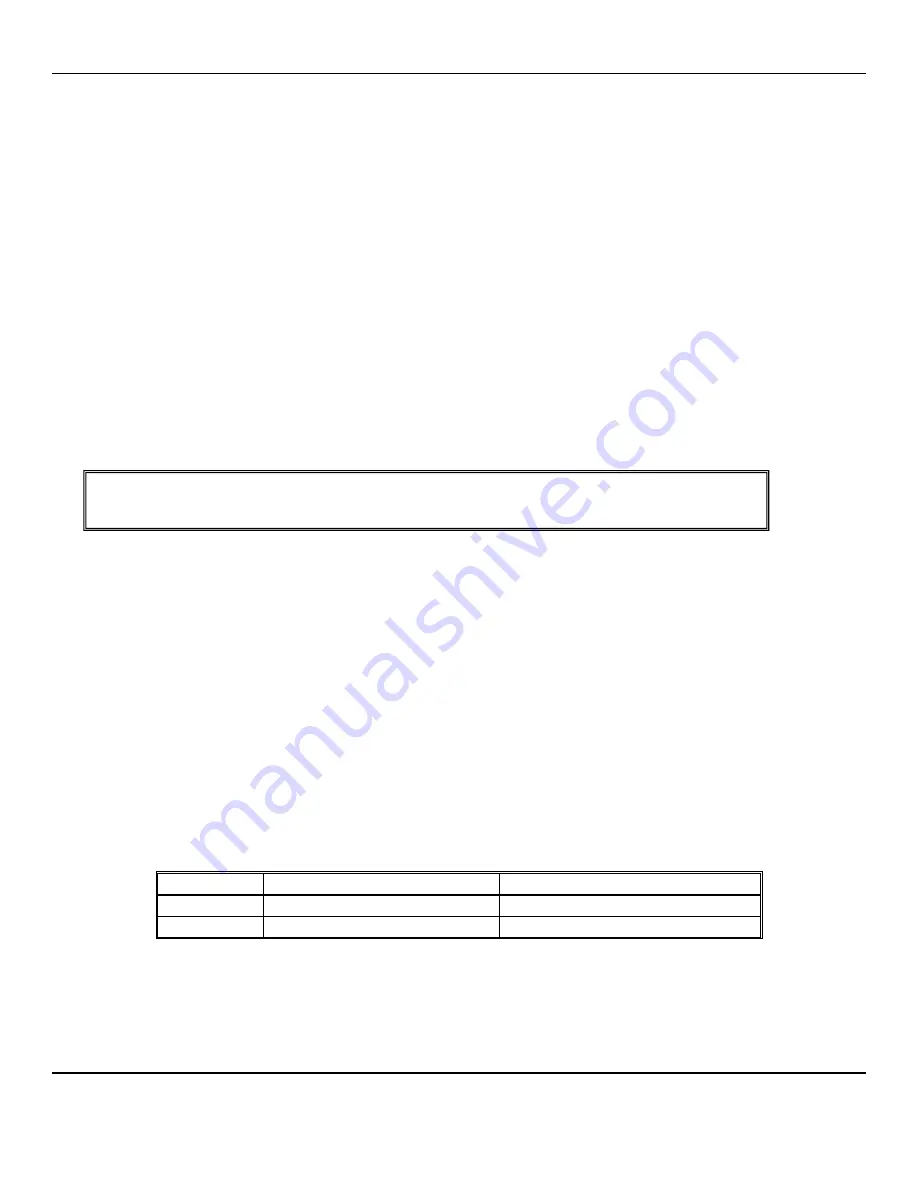

Table 4: Calibration Time

Sensor Type Calibration Gas Concentration

Calibration Gas Application Time

Catalytic

% LEL

1 – 2

minutes

5.2.3 Exit Maintenance Menu

Exit maintenance, by tapping on the

M

ENU

switch until Exit appears on the display. Then Tap the

S

ELECT

switch to return to

the instrument Normal Gas Display.

N

OTE

:

You can change the Calibration Gas Level. H

OLD

the magnet over the S

ELECT

switch for 2 – 4 seconds

The M

ENU

switch changes digit indicated by underscore cursor

The S

ELECT

switch locks underscored digit and moves to next digit