EX-5100 C

OMBUSTIBLE

ENMET

14

6.0 Replacement Part Numbers

ENMET

replacement part numbers:

Description

Part Number

Sensor, Catalytic * (Optional)

03070-001

Sensor, Catalytic * (Standard)

03070-003

Overlay

06000-058

Magnet

50030-001

Calibration Cover

03620-015

Regulator

02506-004

Calibration Gas, Consult

ENMET

Distributor or

ENMET

.

N

OTE

:

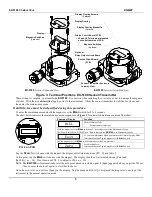

The proper calibration cover must be used for the sensor in use, as indicated above. See also Figure 4.

* See Section 3.2 Wiring

EX-5100

to a Control Unit on page 4 for identification of sensors.

7.0 WARRANTY

ENMET

warrants new instruments to be free from defects in workmanship and material under normal use for a period of one

year from date of shipment from

ENMET

. The warranty covers both parts and labor excluding instrument calibration and

expendable parts such as calibration gas, filters, batteries, etc... Equipment believed to be defective should be returned to

ENMET

within the warranty period (transportation prepaid) for inspection. If the evaluation by

ENMET

confirms that the

product is defective, it will be repaired or replaced at no charge, within the stated limitations, and returned prepaid to any

location in the United States by the most economical means, e.g. Surface UPS/FedEx Ground. If an expedient means of

transportation is requested during the warranty period, the customer is responsible for the difference between the most

economical means and the expedient mode.

ENMET

shall not be liable for any loss or damage caused by the improper use of

the product. The purchaser indemnifies and saves harmless the company with respect to any loss or damages that may arise

through the use by the purchaser or others of this equipment.

This warranty is expressly given in lieu of all other warranties, either expressed or implied, including that of merchantability,

and all other obligations or liabilities of

ENMET

which may arise in connection with this equipment.

ENMET

neither assumes

nor authorizes any representative or other person to assume for it any obligation or liability other than that which is set forth

herein.

NOTE:

When returning an instrument to the factory for service:

Be sure to include paperwork.

A purchase order, return address and telephone number will assist in the expedient repair and return of your unit.

Include any specific instructions.

For warranty service, include date of purchase

If you require an estimate, please contact

ENMET

.

There are Return for Repair Instructions and Form on the last pages of this manual. This Form can be copied or used as needed.

Manual part number

80003-096

December 2003

MCN-313a, 01/27/04

MCN-323, 10/19/04

MCN-361, 11/30/06

MCN-386, 10/10/07

MCN-416, 04/03/09

Calibration Cover

03620-015