EX-5100 C

OMBUSTIBLE

ENMET

7

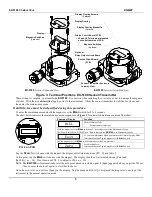

4.2 Normal Display Mode

When the

EX

-

5100

is installed as described in section 3, and in clean air, the

POWER

green LED is on, the display is lit and

the information on the display is measurement of the target gas detected by the

EX

-

5100.

The red alarm and fault LEDs are

not lit.

To advance through displays of operational information tap the magnet over the

M

ENU

button.

N

OTE

:

Software revision may cause variations of display output.

See sequence of operational information below:

Display Measurement of the target gas

Tap the magnet over the

M

ENU

button

Display indicates Alarm 1 Set point

Tap the magnet over the

M

ENU

button

Display indicates Alarm 2 Set point

Tap the magnet over the

M

ENU

button

No Function for the

S

ELECT

button

in this mode

Display indicates Alarm 3 Set point

Tap the magnet over the

M

ENU

button

Display indicates mA Span range

(Full Scale)

Tap the magnet over the

M

ENU

button

Display returns to gas measurement

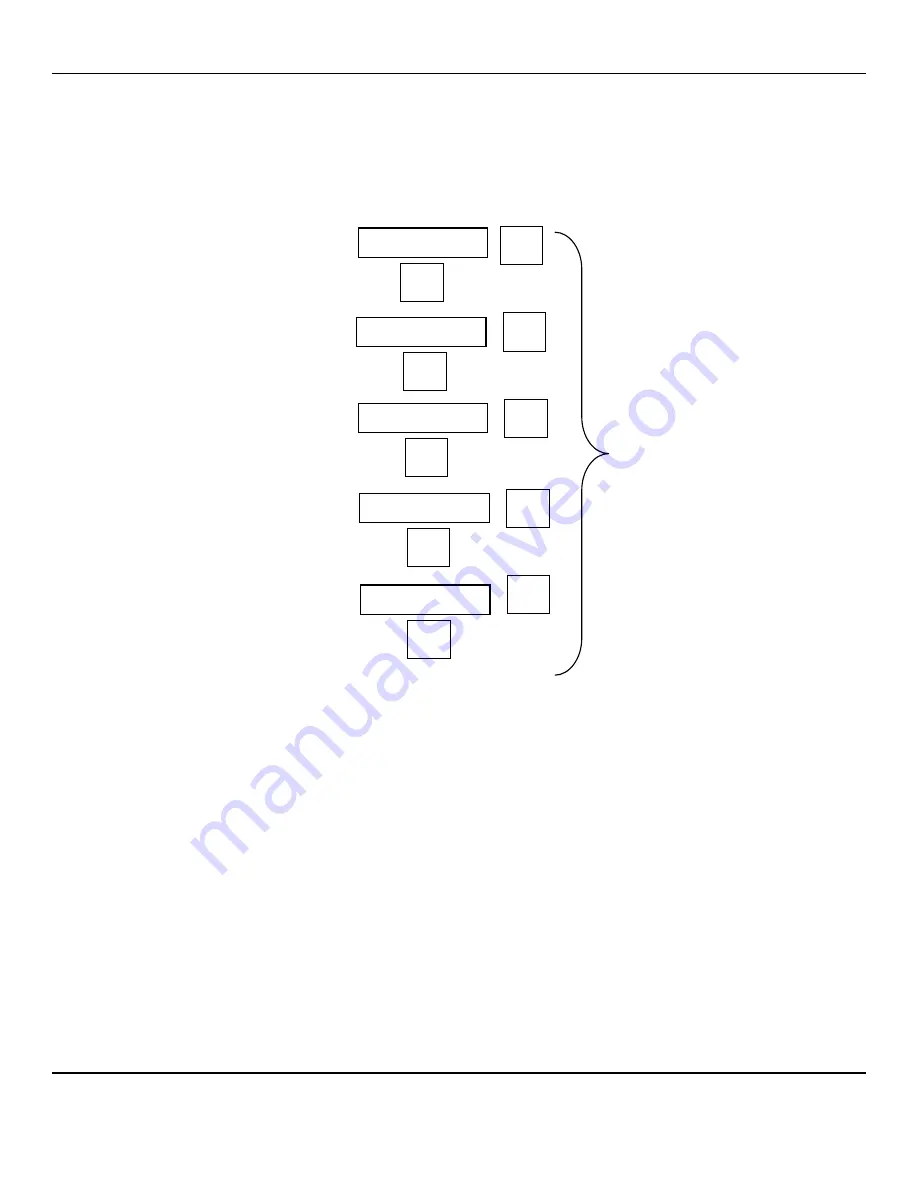

Operational Display Flow Chart

4.2.1 Alarm Conditions

EX

-

5100

There are three alarm set points available. These alarm set points can be changed within limits; see the maintenance section of

this manual for the procedure.

If the gas concentration increases above that of the alarm set point, the associated red LED is lit.

0LEL

A1:

10

S

ELECT

S

ELECT

M

ENU

M

ENU

A2:

20

S

ELECT

M

ENU

A3:

50

S

ELECT

M

ENU

mA:

100

S

ELECT

M

ENU