EX-5130-IS

ENMET Corporation

4

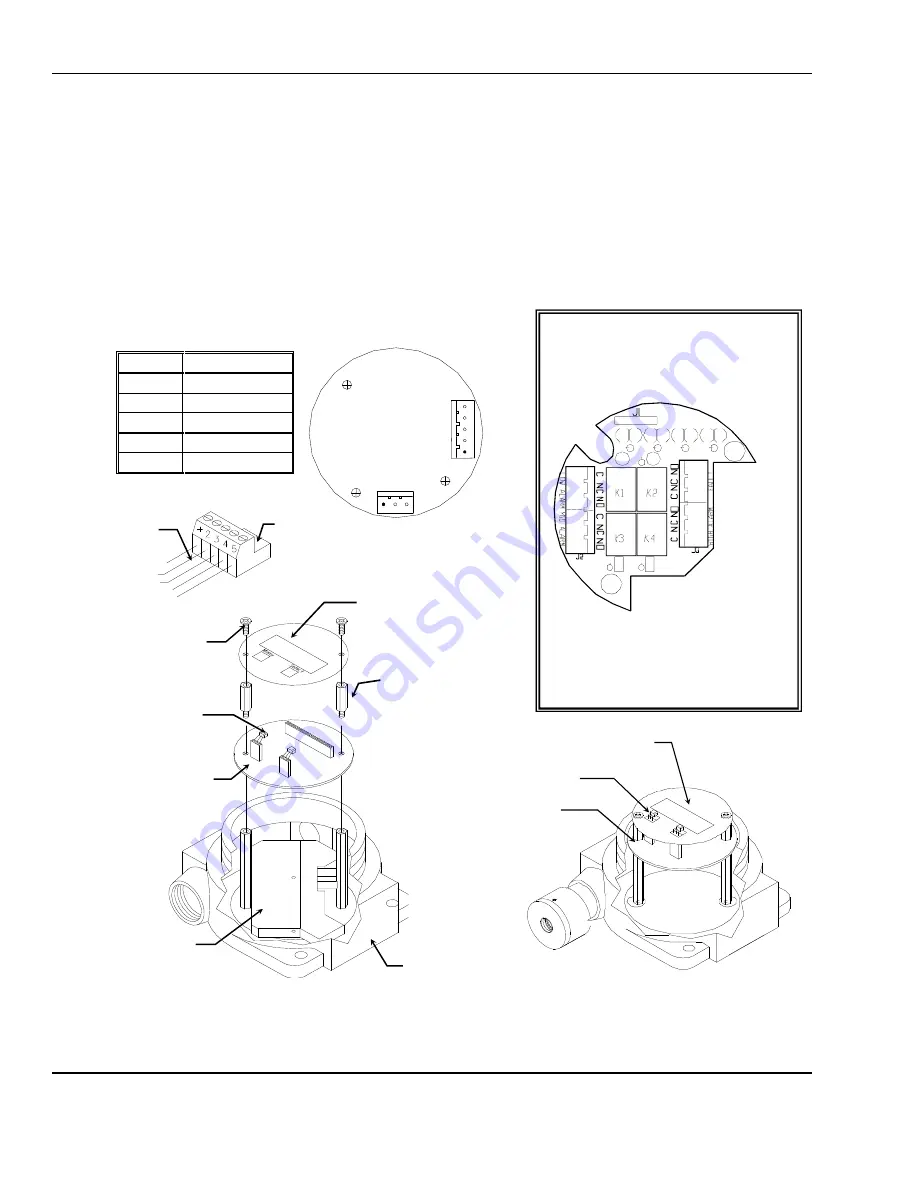

3.2 Wiring the EX-5130-IS to a Control Unit

C

AUTION

:

Area must be declassified during installation.

Run conduit and 16

AWG

(1.5

MM

2

)

wires to the enclosure from the power supply and controller. If the

EX-5130-IS

is

installed in a hazardous location as defined by the National Electrical Code, then ALL wiring must be in accordance

with the National code and any local governing codes.

Open the enclosure, and remove the 2 screws that retain the display overlay to the circuit board.

Use caution when removing the over lay. Do not damage the magnetic switches.

Remove the two overlay standoffs and remove the circuit board, exposing the terminal strips on the bottom of the

circuit board. Do not disconnect the circuit board wiring.

Connect the wires from the controller (power supply) to the supplied J4 plug then attach to J4 terminal.

Connect the wires from the sensor to the supplied J8 plug then attach to the J8 terminal.

See Figure 3 for locations

J4

P

LUG

–

T

ERMINAL TO

C

ONTROLLER

W

IRING

Position

Function

1 +

24

V

DC

power

2

GND

3

4 - 20 mA out

4*

RS-485 D+

5*

RS-485 D–

*Contact

ENMET

for Modbus

Address information

Figure 3: Terminal Positions EX-5130-IS Sensor/Transmitter

When wiring is complete, reassemble the

EX-5130-IS

. Use caution when installing the overlay so as not to damage

the magnetic switches. Put the cover back on the S/T Do Not apply power to the S/T without the cover in place.

Sensor/Transmitter Enclosure

Cutaway View

Display Overlay Screws

(2 places)

Display Overlay

Standoffs (2 places)

Magnetic Switches

(2 places)

Printed Circuit Board (PCB)

J4 and J8 Terminals are

located on the bottom

side of PCB

Display Overlay

Intrinsic Safety

Barrier

Printed Circuit

Board (PCB)

Display Overlay

Magnetic Switches

(2 places)

Optional Relay Output Board

It is recommended that the auxiliary

alarm be powered separately.

Use 14 – 20

AWG

(2.5

–

0.5

MM

2

) wire.

When on power the relays are energized.

Relays are rated at 0.5 Amp continuous.

Relay Output Board

Bottom View

N

OTE

: Auxiliary alarms should be powered from an

independent power source separate form the

instrument power to avoid alarm failure due to

controller malfunction.

All wiring must be in accordance with the

National Code and any local governing codes.

5

4

3

2

1

J 4

J 8

1 2 3

Circuit Board

Bottom View

P l u g J 4

To J4

Wires to

Controller