eno

one 2/r - user manual

REV.05

14

250 mm 9.85 inch

100 mm

3.94 inch

352 mm

13.86 inch

A

B

AIR OUTLET

COOLING

AIR INLET

COOLING

14. CONNECTING THE GAS

The operations described below must be carried out by personnel

authorised by the manufacturer or who have been adequately trained.

The use of gloves during the operations to connect the gas and to

replace the cylinder is recommended.

The Dispenser must be connected to a source of food-use inert gas, see table

below.

GAS PERMITTED

Argon (E938)

Nitrogen (E941)

The gas is not supplied together with the Dispenser and can be purchased directly

from the Enomatic retailer or from an authorised retailer of food-use gas in the con-

tainers described below:

•

Disposable cylinder

•

Refillable cylinder

In the event of high use of the Dispenser, it is advisable to use a

Nitrogen Generator

that is exclusively available from the retailer Enomatic.

Ask the retailer for information on the best choice to suit

your needs.

THE FOLLOWING EXAMPLE ILLUSTRATES THE STEPS TO CONNECT A DIS-

POSABLE CYLINDER WITH ITS PRESSURE REGULATOR TO THE DISPENSER

The gas connection pipe, supplied with the Dispenser (para. 6), is delivered to you

in a length of 0.70 m / 27.56 in, to place the cylinder in the relevant rear space ac-

companied by the strap (

E

). To position the cylinder away from the Dispenser and

to accommodate it, for example, inside the door of any cabinet on which you will be

positioning the Enomatic device, contact the Retailer with regard to the gas con-

nection pipe of the desired length.

INSTALLATION

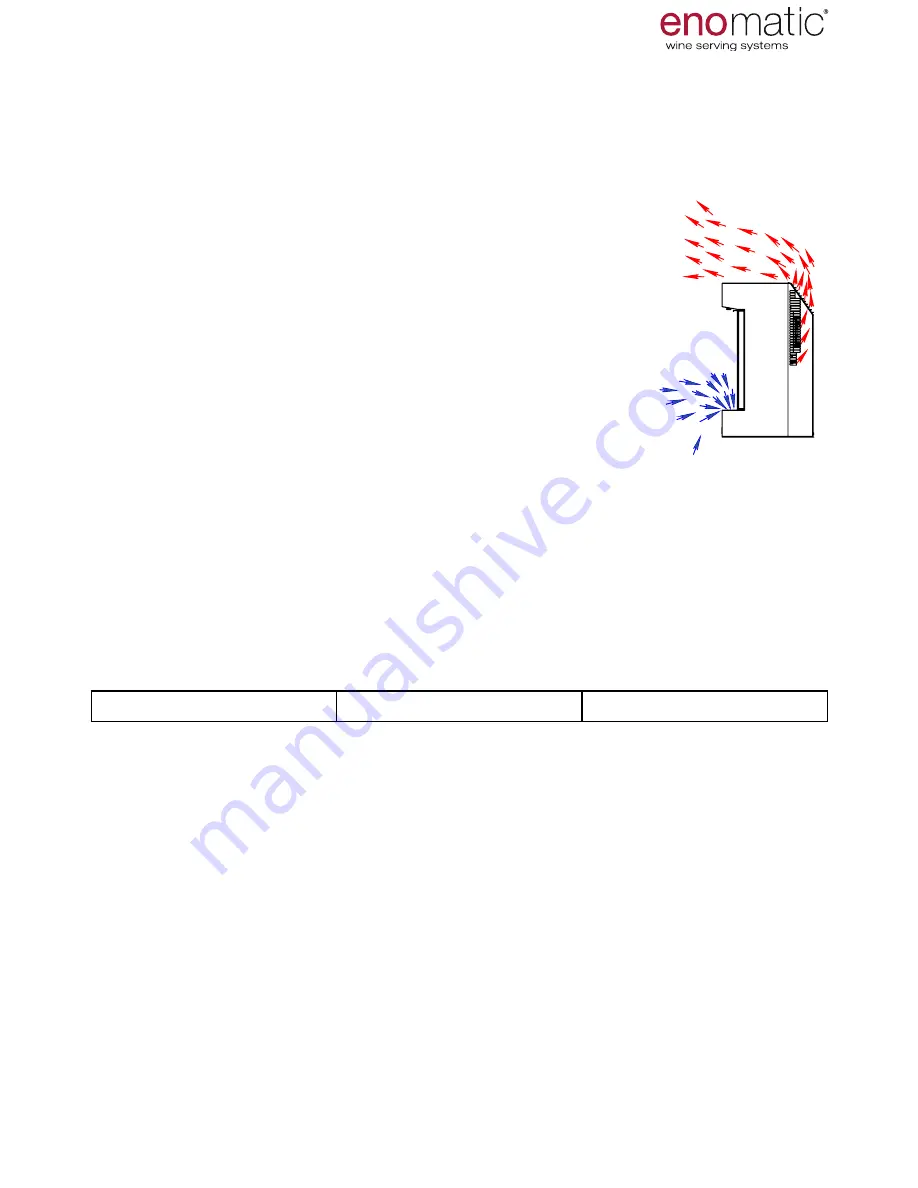

13. THERMOELECTRIC REFRIGERATION SYSTEM

The dispenser has a thermoelectric refrigeration system (

O

) controlled by an elec-

tronic board which regulates the temperature of the bottle compartment via a de-

tection probe

(

Q

).

The system draws in the air from the drip grill

(

C

)

and expels it

through the rear aeration grills

(

D

).

Do not place any object on or within the com-

ponents (C) and (D), check constantly that they are not blocked.

Clean the grills constantly referring to

the

scheduled maintenance table (para. 41)

and perform the recommended daily and

annual cleaning (para. 48.

Do not leave the cooling system acti-

vated with the door open. During oper-

ations on Dispenser that involve

continuous or protracted openings of

the

door, such as emptying of the ducts or

replacement of the bottle, it is recom-

mended to switch off the refrigeration

setting the temperature to "OFF" = off

(para. 23).

IMPORTANT

For correct operation and duration over time, carefully follow the information

indicated above.