eno

one 2/r - user manual

REV.05

47

51. TROUBLESHOOTING

Any repair work on the mechanical parts and on the electrical system must be per-

formed with electrical voltage removed (with the power cable of the Dispenser dis-

connected from the mains socket) and only by authorised technicians.

Inattention and/or incorrect performance of the actions indicated in this manual

may cause malfunctions that can be solved by the actual user.

The following information is intended to help identify and correct faults and mal-

functions that may occur during use. If the problem persists or is not solved, please

contact the Authorised Service Centre or Retailer.

The list of retailers is available at

www.enomatic.com

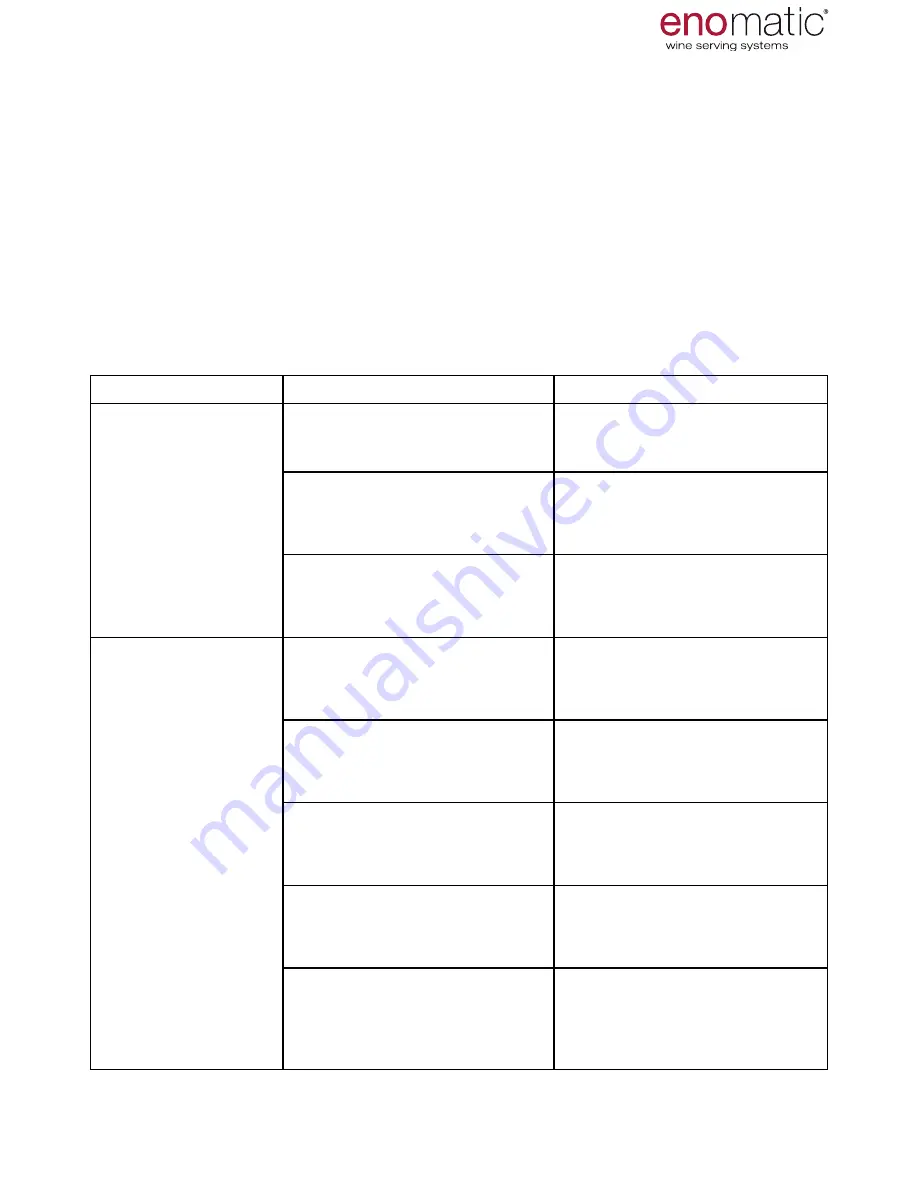

PROBLEM

POSSIBLE CAUSE

SOLUTION

The dispenser

does not

come on

No voltage on the power

supply network

Restore the power supply

(para.15)

Electrical power not activat-

ed

Plug in the power cord and

turn the main switch to the

position "I" = ON (para.16)

Power cable

visibly damaged

Request a new power cable

from the Retailer

The Dispenser

does not suffi

-

ciently cool

the compartment

Unsuitable ambient condition Position the Dispenser in an

appropriate ambient (para.12)

The installation spaces are

not respected

Restore the correct installa-

tion spaces (para.12)

Drip grill and aeration grills

are obstructed by objects or

dirt

Remove any objects or clean

the air grills (para.41)

The door is not properly

closed or is opened

Dry off any condensation on

the bottle compartment and

close the door (para.42)

A high temperature value has

been set or the refrigeration

system has been disabled

(OF)

Change the setting of tem-

perature, according to re-

quirements (para.23)

TROUBLESHOOTING