IQ 7 / IQ 7+ / IQ 7X / IQ 7A Micro Installation and Operation

© 2020 Enphase Energy Inc. All rights reserved.

141-00043-03

15

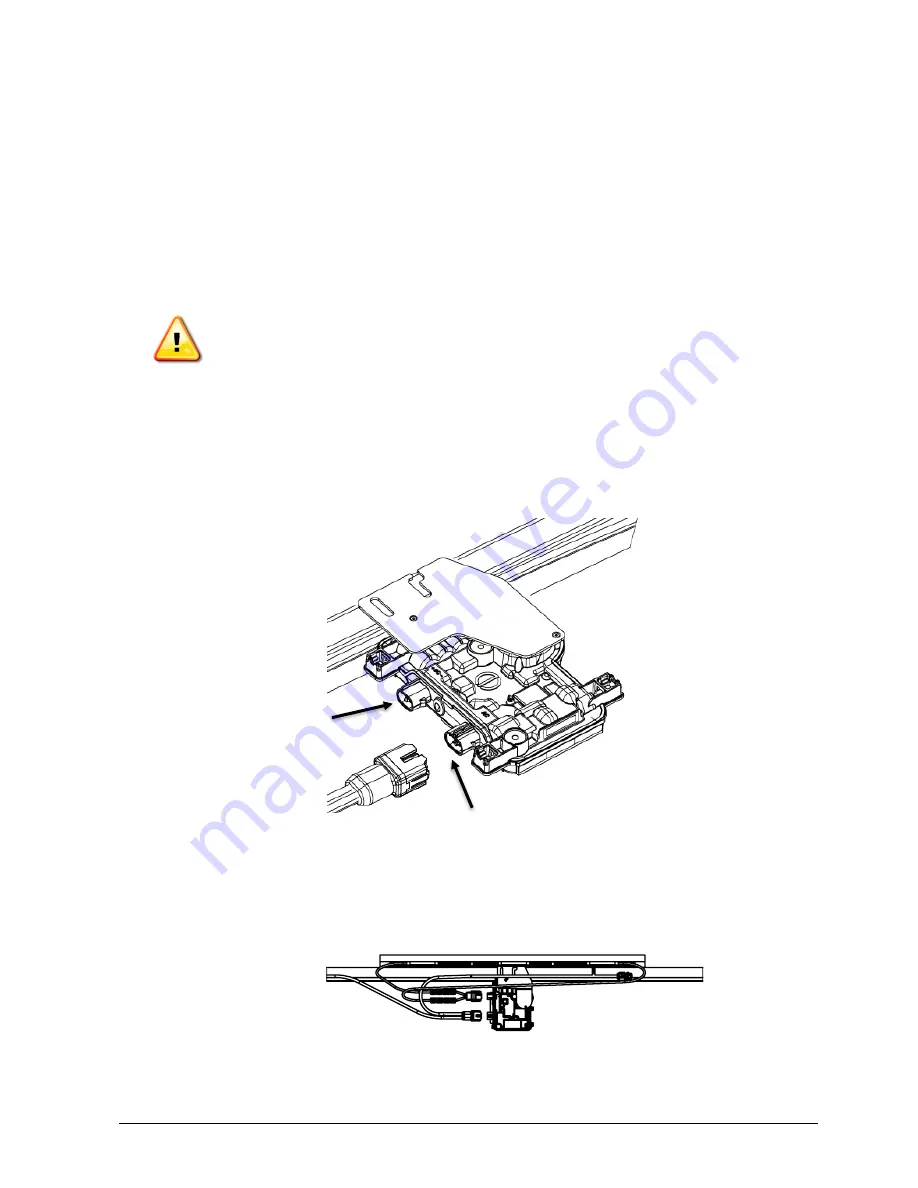

Step 3: Mount the Microinverters

A.

Mount the microinverter horizontally bracket side up or vertically.

•

Always place the microinverter under the PV module, protected from direct

exposure to rain, sun, and other harmful weather events. Allow a minimum of 1.9

cm (3/4

”) between the roof and the microinverter. Also allow 1.3 cm (1/2”)

between the back of the PV module and the top of the microinverter.

•

For vertical mount, also maintain > 30 cm (12”) clearance from the edges of the

PV module to protect the microinverter from direct exposure to rain, UV, and

other harmful weather events.

WARNING

: Install the microinverter under the PV module to avoid direct exposure to

rain, UV and other harmful weather events. Do not mount the microinverter upside down.

B. Torque the microinverter fasteners as follows.

Do not over torque

.

•

6 mm (¼

”) mounting hardware: 5 N m (45 to 50 in-lbs.)

•

8 mm (5/16

”) mounting hardware: 9 N m (80 to 85 in-lbs.)

•

When using UL 2703 mounting hardware, use the manufacturer’s recommended

torque value

AC Connector

DC Connector

Horizontal mount

Vertical mount