2

Warning! Risk of electric shock.

To maintain the warranty,

do not modify the cover.

Wire the Grid Connections

A ) Use conductors sized per local code requirements taking into con-

sideration the voltage drop/rise and upstream breaker or fuse. The

terminals accept wire range 1/0 to 250kcmil. Wires must be Class B

or Class C only, and conductors with finer strands are not approved.

Note that the rated maximum breaker size is 250 A.

B ) The terminal lugs on the left with four terminals are for the grid

connection. Install L1 into the left-most terminal, L2 into the second

from the left, L3 into the third from left and neutral at the remaining

terminal. These connections require a 7/16 Allen wrench.

C ) Connect the ground to a ground lug. Ground connections requite

a 5/16 Allen wrench.

D ) Torque all connections as indicated by the

Wiring Table

.

4

Wire Inputs from the Array (AC Branch Circuits)

A ) Use copper conductors sized to meet local code requirements and

voltage drop/rise considerations. The terminals accept wire range 1/0

to 250kcmil. Wires must be Class B or Class C only, and conductors

with finer strands are not approved.

B ) Connect the ground (green or green/yellow) to a ground lug. Ground

connections require a 5/16 Allen wrench, and accept a wire range of 4

to 2/0 AWG.

C ) The terminal lugs on the contactor (on the right side of the box)

with three terminals are for the array connection. Install L1 into the

left-most terminal, L2 into the center, and L3 into the right. These

connections require a 7/16 Allen wrench.

D ) Connect the Array neutral, if required, to the terminal block shared with

the Grid connections.

E ) Torque connections as indicated by the

Wiring Table

.

NOTE

:

Enphase IQ Series Microinverters use a two-wire system and

do not use a Neutral. However, the IQ Envoy in the NPR still requires a

Neutral from the load center.

Warning! Risk of equipment damage.

Observe bend radius

requirements when routing wires.

WIRING TABLE

Grid/Array Connection

Torque

250kcmil - 3/0

275 lbs•in.

2/0 - #6

120 lbs•in.

Copper conductors only, rated minimum 90°C. Follow

NFPA 70 (NEC) or CSA C22.1 part 1 and all local

codes.

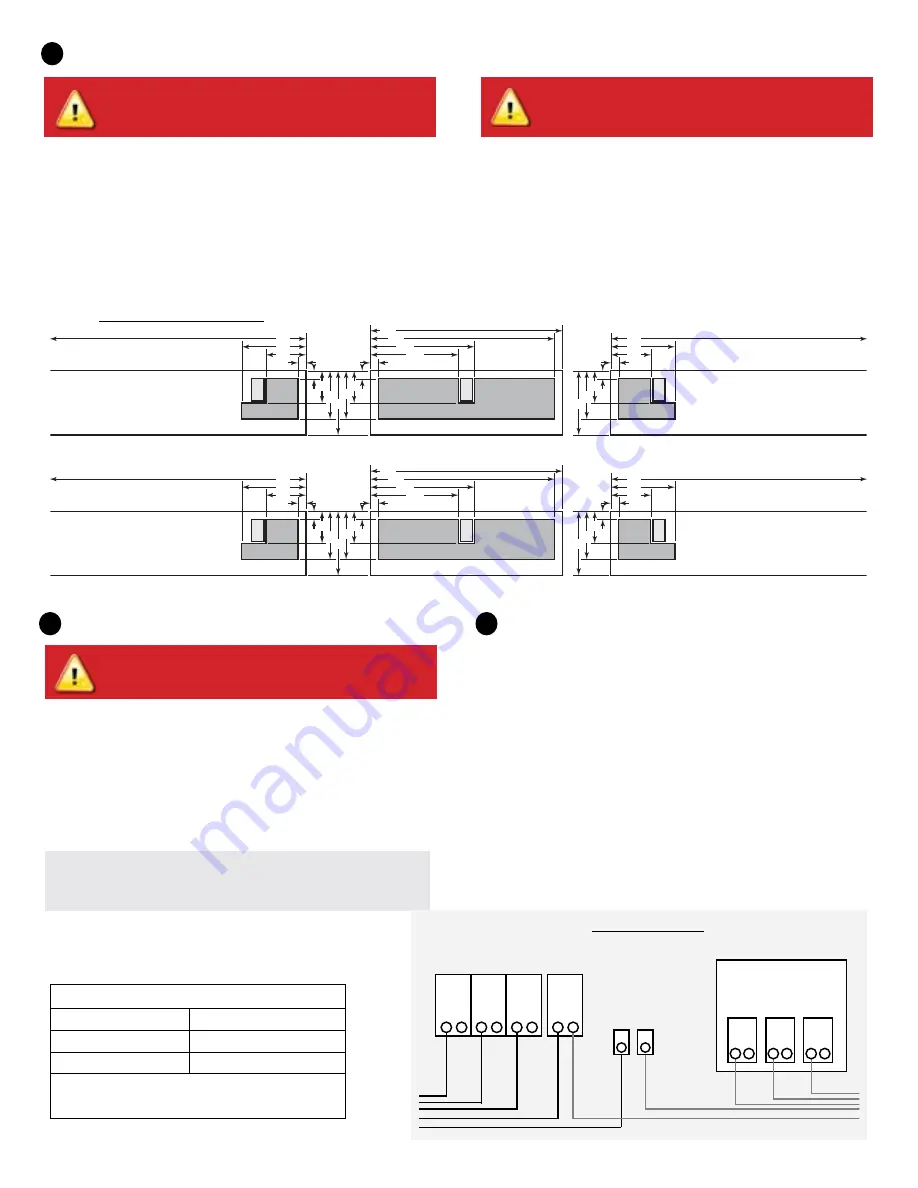

Drill Holes to Accept Conduit

A ) Unlock and open the Three-Phase NPR cover.

B ) See the Conduit Entry diagram for the best locations to drill holes for conduit fittings.

NOTE: When drilling, consider the internal parts of the NPR. Make sure that the holes do not interfere with the internal workings, mechanics, or the cover

legs in the corners of the NPR.

Best Practice:

Use a stepped drill bit to make the conduit holes. Using a hole saw may crack the plastic housing. As an alternative, use a sharp chassis

punch with caution.

C ) Use a snap punch or other type of center punch to prevent the drill from wandering. Drill a pilot hole with a smaller drill before using a step drill bit.

D ) Use only UL-listed rain-tight hubs for wire entry into the enclosure.

3

Warning! Risk of equipment damage.

Do not drill conduit

holes on the top of the box or at any location that allows

moisture ingress.

1”

1”

23”

13”

11”

6”

4”

4”

8”

8”

24”

Conduit Entry

Location Bottom

Side

Conduit

Entry

Right

Side

1”

4.5”

8”

6”

30”

1”

4.5”

8”

30”

Conduit

Entry

Left

Side

Top

Back

1”

4”

6” 1”

25.4

25.4

584

330

279

152

102

102

203

203

610

Conduit Entry

Location Bottom

Side

Conduit

Entry

Right

Side

25.4

114

203

152

762

25.4

114

203

762

Conduit

Entry

Left

Side

Top

Back

25.4

102

152 25.4

Inches

mm

GRID

Contactor

L1

L2

L3

N

L1

L2

L3

GRID/

ARRAY

ARRAY

GND

Black

Red

Blue

W

hit

e

W

hit

e

Black

Red

Blue

Gr

n/Y

ello

w

Gr

n/Y

ello

w

Conduit entry diagram

Wiring diagram