10

TBE-250 Instruction Manual

Feb 2012

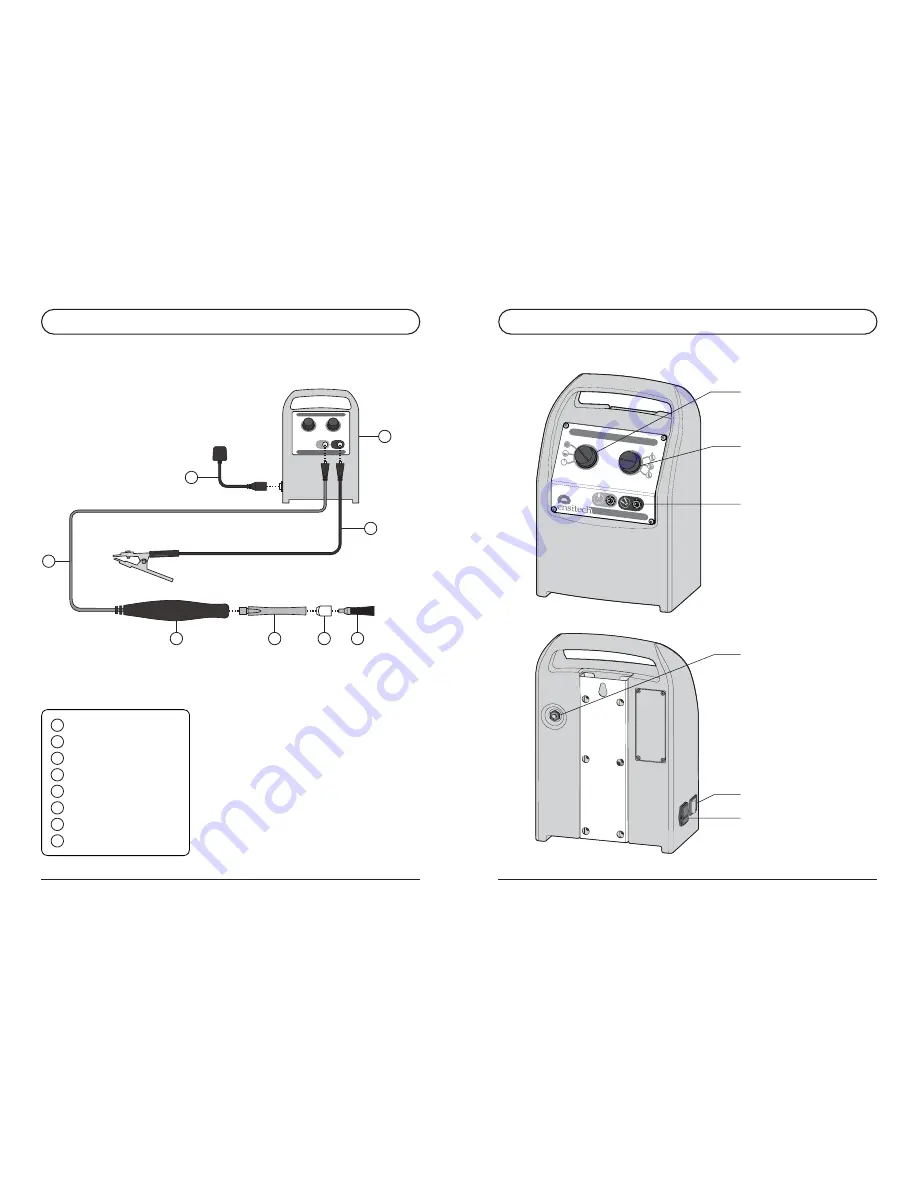

S3 DESCRIPTION OF APPARATUS

1

2

4

5

6

7

8

3

1

2

3

4

5

6

7

8

TIG Brush Control Unit

Clamp Cable

Handle Cable

Handle

Wand

Shroud

Brush

Power Cord

11

Ensitech Pty Ltd

www.ensitech.com.au

TBE-250

TIG

Brush

®

S3 DESCRIPTION OF APPARATUS

Power Control

Mode Control

Cable Sockets

Reset Button

On/Off Switch

Mains Socket