16

TBE-250 Instruction Manual

Feb 2012

S6 MAINTENANCE

MAINTENANCE

•

When not in use, ensure the On/Off switch is OFF. The

green power light on the front panel and the On/Off

switch should not be illuminated.

•

Rinse brush with water to remove excess cleaning fl uid.

•

At completion of a work shift, unscrew brush from

wand. Remove the brush from the insulating shroud

and rinse brush, shroud and end of wand with water to

remove cleaning solution. Allow to dry before

re-assembling.

•

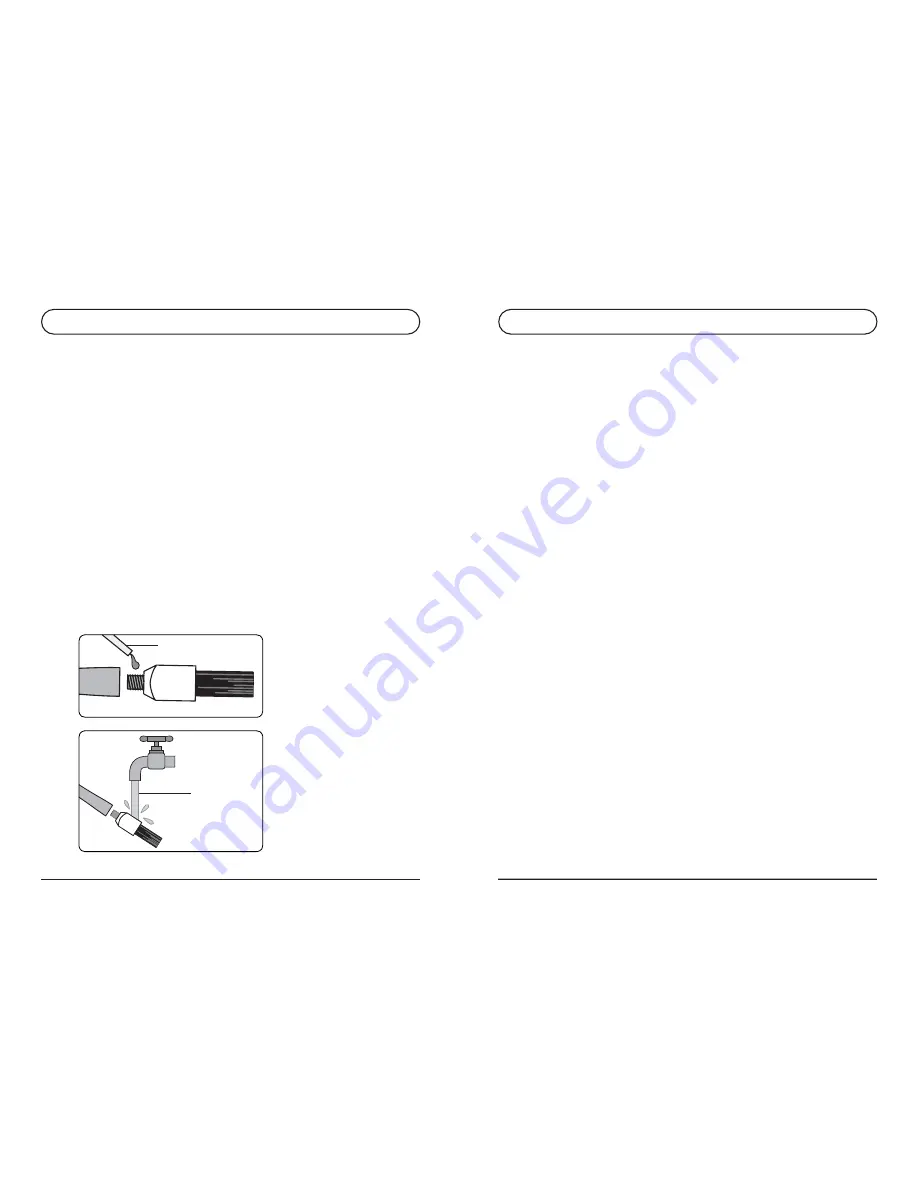

Before assembling the brush to the wand, coat threads

with copper fi lled anti-seize compound. This will exclude

the acidic solution from the joints and prevent corrosion.

•

Rinse clamp with water to remove solution and

prevent corrosion.

•

Use a wet cloth to wipe fl uid splashes off the TIG Brush

control unit. After some time splashes and marks may

accumulate and become diffi cult to remove.

Rinse brush

components

after use

Wand

Brush

Anti-seize compound

6.1

5

Ensitech Pty Ltd

www.ensitech.com.au

REVISIONS LOG

REVISIONS LOG

Original Issue of Manual: May 2010

Revision: February 2012