6

TBE-250 Instruction Manual

Feb 2012

INTRODUCTION

SAFETY PRECAUTIONS

DESCRIPTION OF APPARATUS

OPERATION

4.1

Preparation

4.2

Assembly

4.3

Cleaning Fluid

4.4

Operation

POWER AND GRADE SETTING

5.1

Power Settings

5.2

Mode Settings

MAINTENANCE

CONSUMABLES

7.1

Brushes

7.2

Insulating Shroud

7.3

Cleaning Fluid

7.4

Neutralising Fluid

7.5

Marking Fluid

7.6

Other Fluids

TROUBLESHOOTING

8.1

On/Off Switch Not Illuminated

8.2

On/Off Switch Illuminated & Front Panel

Power Light Not Illuminated

8.3

On/Off Switch & Front Panel Power Light

Illuminated & Unit Not Operating

7

8

10

12

12

12

12

14

15

15

15

16

17

17

17

17

17

17

17

18

18

18

19

CONTENTS

S1

S2

S3

S4

S5

S6

S7

S8

15

Ensitech Pty Ltd

www.ensitech.com.au

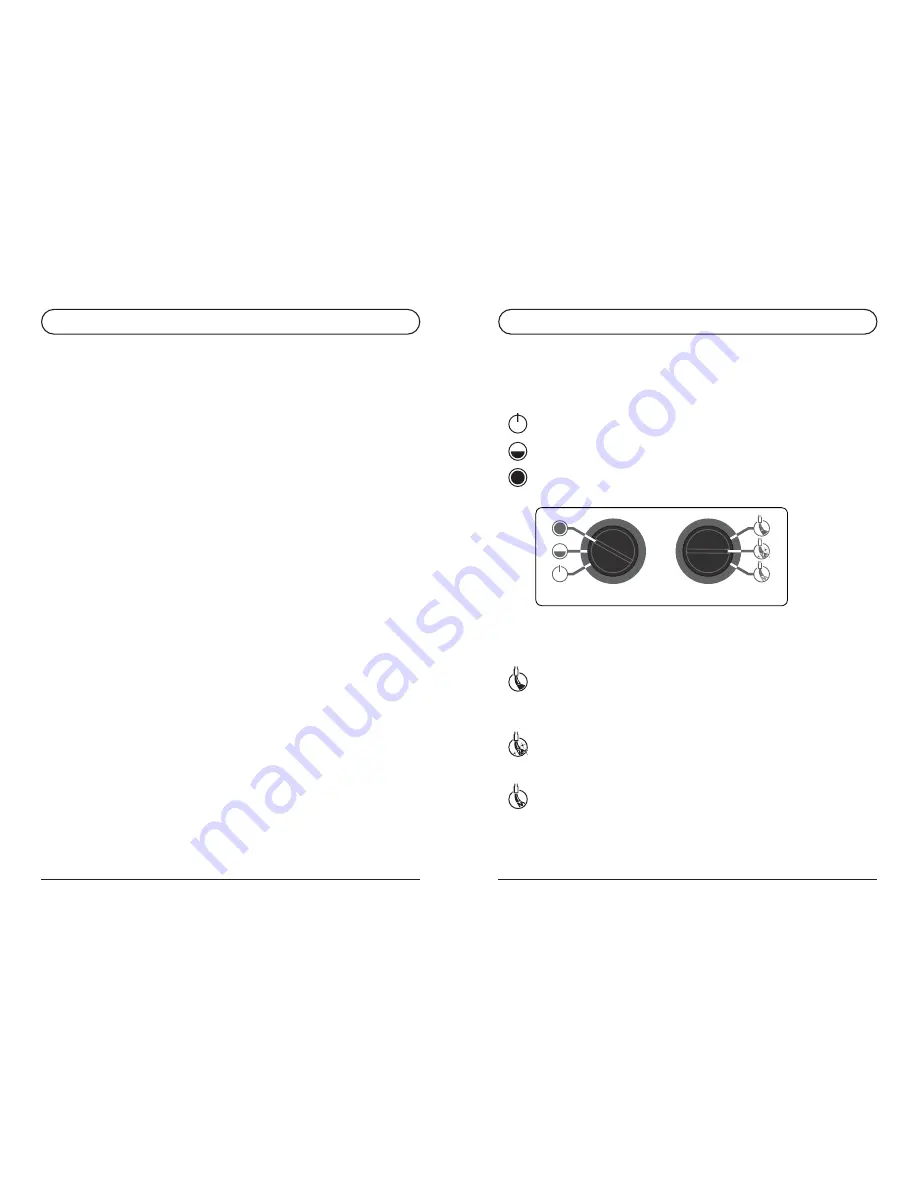

S5 POWER AND GRADE SETTINGS

MODE SETTINGS

POWER CONTROL

MODE CONTROL

5.2

POWER SETTINGS

5.1

Choose the cleaning intensity required by selecting the

appropriate setting using the Power Control.

STANDBY

- Power is not transmitted to the brush.

LOW

- Use for light work and thin metals.

HIGH

- Use for most cleaning operations. Provides fastest

cleaning speed.

Choose the type of cleaning required by selecting the

appropriate setting using the mode control.

CLEAN

- This mode provides the fastest cleaning at each

power setting. However, prolonged use may cause a milky

appearance on the surface of the metal. If this happens, use

RESTORE to rectify.

RESTORE

- This mode provides metal polishing. Use this

grade to repair a dull white surface, including one caused by

over-use of CLEAN.

MARKING

- This mode provides surface marking, when used

with the appropriate chemical.