8

TBE-250 Instruction Manual

Feb 2012

S2 SAFETY PRECAUTIONS

Protect yourself and others by observing all safety

information, warnings and cautions. Failure to comply with

instructions could result in personal injury and/or damage to

the product or property.

Read this documentation carefully before operating the

equipment. Please retain these instructions for future

reference.

Before using the TIG Brush, make sure the work environment

is well ventilated and away from any combustible

substances. Ensure that all required equipment is available.

Do not use the TIG Brush for any purpose other than that

described in this manual. Failure to observe this warning

may result in permanent damage to the TIG Brush, cause

damage to the workpiece, cause injury to the operator and

void the warranty.

The TIG Brush is one of the safest appliance in its class.

However some precautions must be taken with the use of

the TIG Brush, as with any electro-cleaner.

•

The TIG Brush uses mild acids; gloves should be used to

avoid prolonged contact with any of the fl uids.

•

Goggles should be worn to prevent fl uid being splashed

in the eyes.

SAFETY PRECAUTIONS

SAFETY INFORMATION

WARNING

13

Ensitech Pty Ltd

www.ensitech.com.au

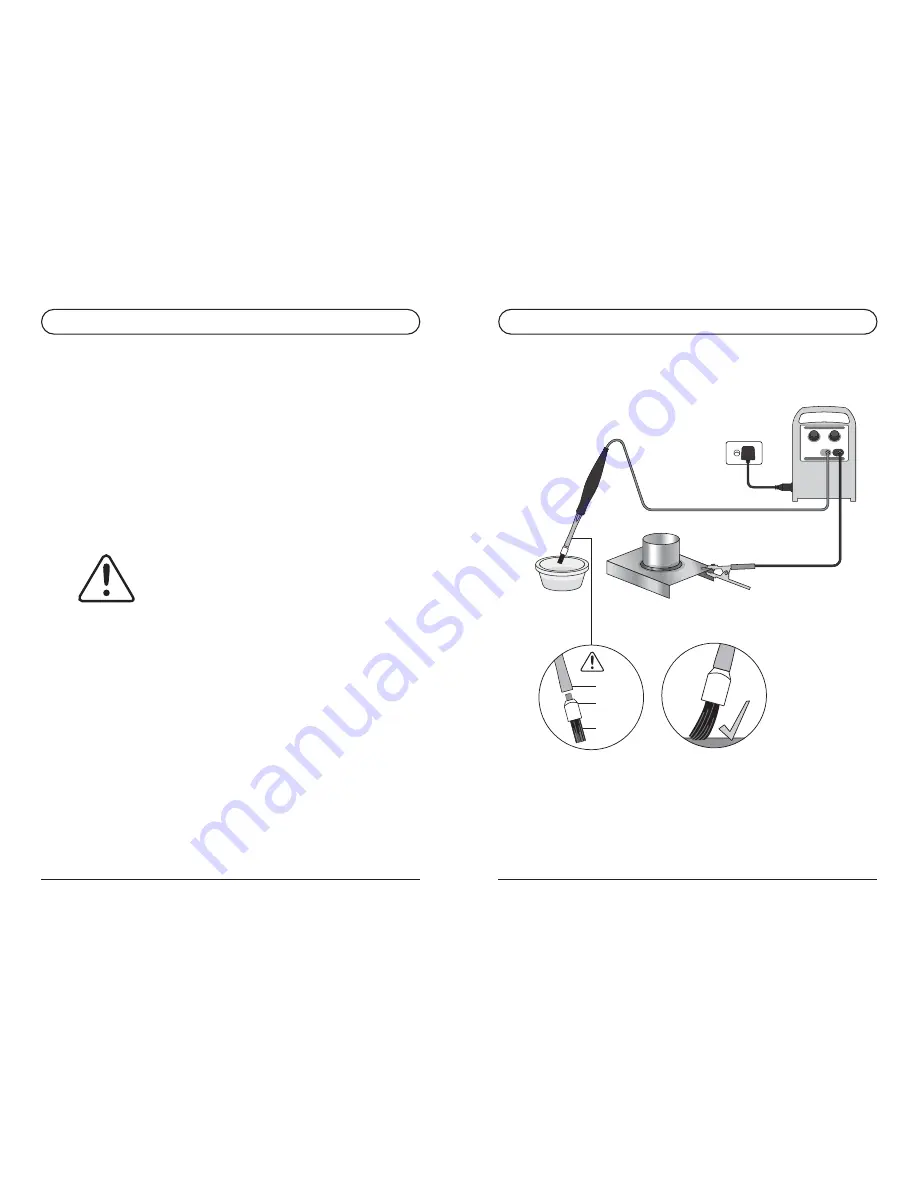

S4 OPERATION

Workpiece

For best performance

use tip of brush only

Wand

Brush

Shroud

Insulating shroud

must be used