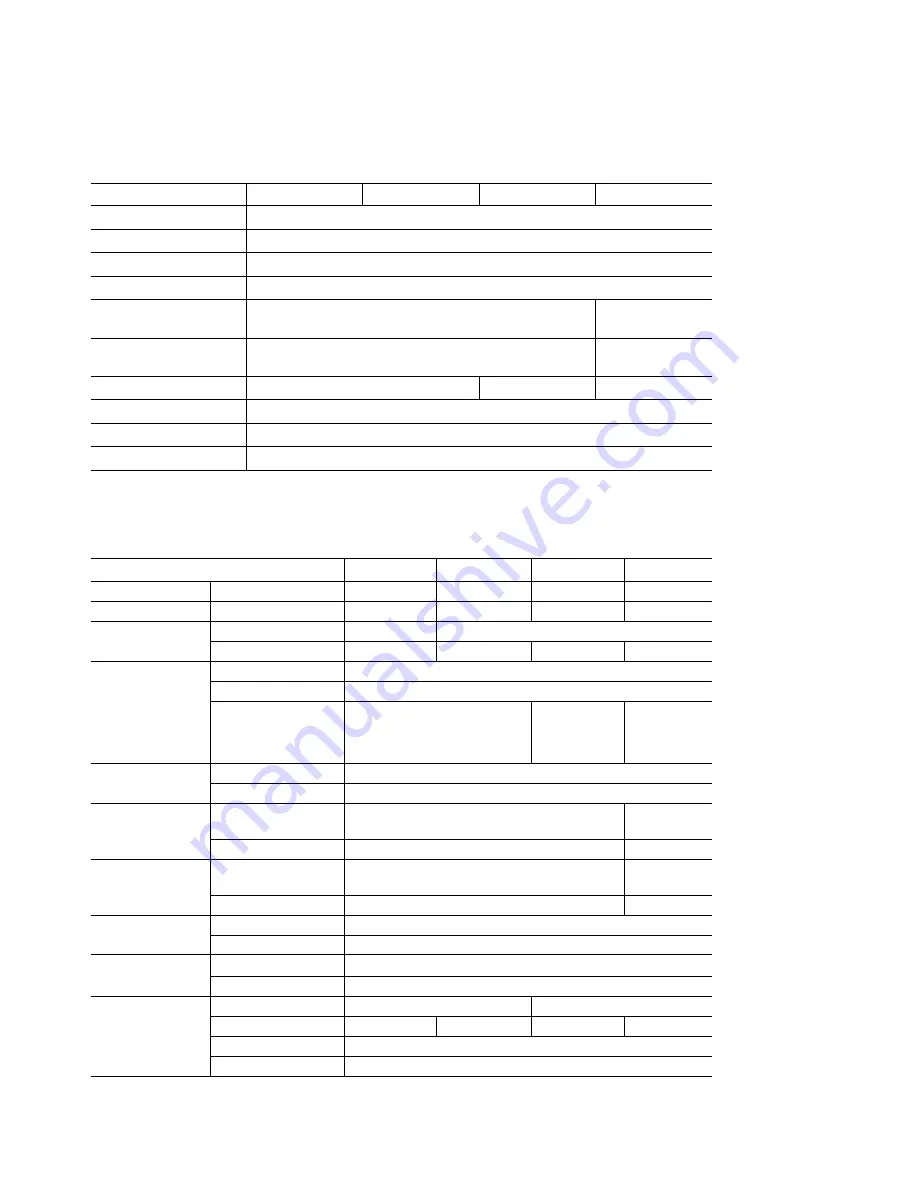

Model

PGPS4

EGPS4

EGPS8

EGPS12

Gases purified

H

2

Media type

Inorganic

Contaminants removed

H

2

O, CO, CO

2

, O

2

and nonmethane hydrocarbons

Outlet purity

<1 part-per-billion (ppb)*

Operating pressure range

515–1825 kPa (60–250 PSIG)

1136 kPa

(60–150 PSIG)

Pressure drop

<15 PSI @ 120 PSIG inlet and max rated flow

<17 PSI @ 90 PSIG

and max rated flow

Maximum flow rate

120 SLM

300 SLM

1000 SLM

Gas operating temperature

-40°C to +60°C (-40°F to +150°F)

Outlet filtration

0.003 micron @ 99.9999999% efficiency

Leak rating

1

×

10

–9

atm cc/sec.

Product Specifications

*Outlet purity is significantly lower for some contaminants. Test data available upon request.

Facility Specifications

It is the customer’s responsibility to ensure that the equipment is installed according to local building code requirements.

Specifications

PGPS4

EGPS4

EGPS8

EGPS12

Process gas input

Mechanical connection

1

⁄

4

″

face seal

1

⁄

4

″

tube stub

1

⁄

2

″

tube stub

3

⁄

4

″

tube stub

Process gas output

Mechanical connection

1

⁄

4

″

face seal

1

⁄

4

″

tube stub

1

⁄

2

″

tube stub

3

⁄

4

″

tube stub

Ventilation

Mechanical connection

N/A

4

″

duct

Exhaust flow

N/A

50 CFM

100 CFM

65 CFM

Power requirements

Mechanical connection

Standard terminal

Power requirements

200–240 VAC

Power consumption

50W at idle and process mode;

300W during regen

50W at idle and

process mode;

800W during

regen

50W at idle and

process mode;

1000W during

regen

Regeneration

Max regen frequency

3 days (May be configured per customer inlet gas purity)

Regen duration

48 hours

Regen gas input 1

Gas

N/A

N

2

515–929 kPa

(60–120 PSIG)

Mechanical connection

N/A

1

⁄

4

″

tube stub

Regen gas input 2

Gas

N/A

H

2

515–929 kPa

(60–120 PSIG)

Mechanical connection

N/A

1

⁄

4

″

tube stub

Regen gas output

Pressure

Atmospheric

Mechanical connection

1

⁄

4

″

tube stub

Instrument air

Gas and pressure

CDA or N

2

@ 653 –791 kPa (80 –100 PSIG)

Mechanical connection

1

⁄

4

″

compression fitting

Physical requirements

Mounting

Wall

Floor

Shipping weight

32 kg (70 lbs)

39 kg (85 lbs)

113 kg (250 lbs)

205 kg (450 lbs)

Operating conditions

15°–40°C indoor (60°–104°F indoor)

Humidity

10–90% RH noncondensing