44

IP2159EN - 2017-06-12

20. Parallel automations (DAB905SYN)

20.1 Settings

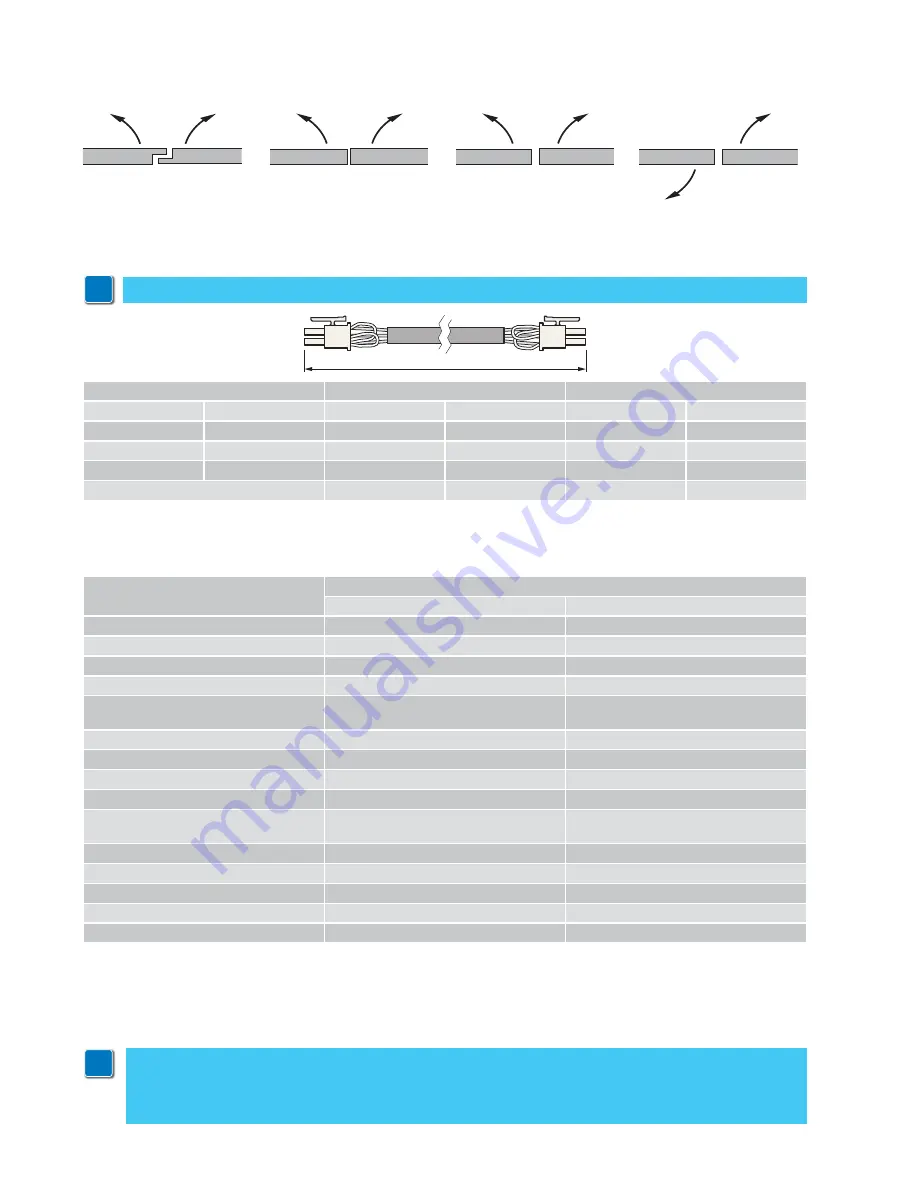

Connect the two automations to the plug on the control panel, using the synchronisation cable (DAB905SYN).

Depending on the type of installation, cut the jumpers on the MASTER or SLAVE cable, as shown in the table:

MASTER

SLAVE

black

2000 mm

yellow

blue

red

Operating mode

Type of application

Jumper to be cut

Opening

Closure

Overlap

Skim

MASTER

SLAVE

Synchronous

Synchronous

NO

NO

/

/

Synchronous Asynchronous

YES

NO

BLACK

/

Asynchronous

Asynchronous

YES

YES

/

RED

Double exit

/

/

BLACK

RED

Operating mode

Settings

MASTER

SLAVE

Program selection

X

Opening time

X

Closure time

X

Closure time adjustment

X

Closure / Opening attempt when the door is

obstructed

X

Enable / Disable PAG

X

Level of servo-assistance

X

X (*)

Closure force

X

X (*)

Pulse of motion sensor or mat

X

Selection of operating mode during battery

functioning

X

Lock/release signal tension

X

X

Block powered / Unpowered

X

X

Enable / Disable block release

X

X

Open door delay

X

X

Enable / Disable snap block

X

X

•

The electric locks / electric strikes must be connected to the MASTER and SLAVE control panels.

•

The opening devices must be connected to either the MASTER or SLAVE control panel, or to both.

•

The OPD motion sensor must be connected to the MASTER control panel except for double exit doors where each

OPD motion sensor must be connected to the corresponding control panel

•

The sensors fitted on the wing must always be connected to the corresponding control panel.

SORMONTO

SFIORAMENTO

SENZA SFIORAMENTO

DOPPIA USCITA

The MASTER automation is the one that opens first.

i

i

(*) In double exit doors, these functions have to be set separately on the MASTER and SLAVE doors because the arm

system and air pressure may differ.

OVERLAP

SKIM

WITHOUT SKIM

DOUBLE EXIT