35

IP2085EN - 2014-09-01

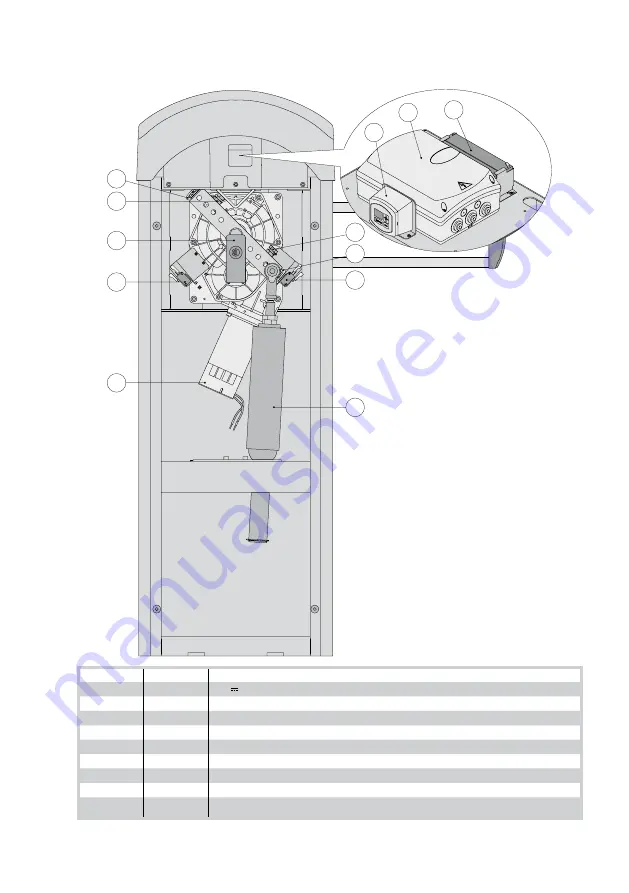

6. Main components

1

5

4

3

2

2

3

4

6

7

8

9

Ref.

Code

Description

1

24 V motor with encoder

2

Opening/closing limit switches

3

Limit switch adjustment

4

Mechanical stop adjustment

5

Key release

6

Blue spring Ø63 mm

7

Control panel

8

BATKH

Continuous mode battery kit

9

MD2

Display module for diagnostics and advanced control