INTRODUCTION

Installation

52 |

P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model:

iPAK2v2

Firmware Version:

V2.10

May 22 | Doc No 700253-2

2.9.3.5

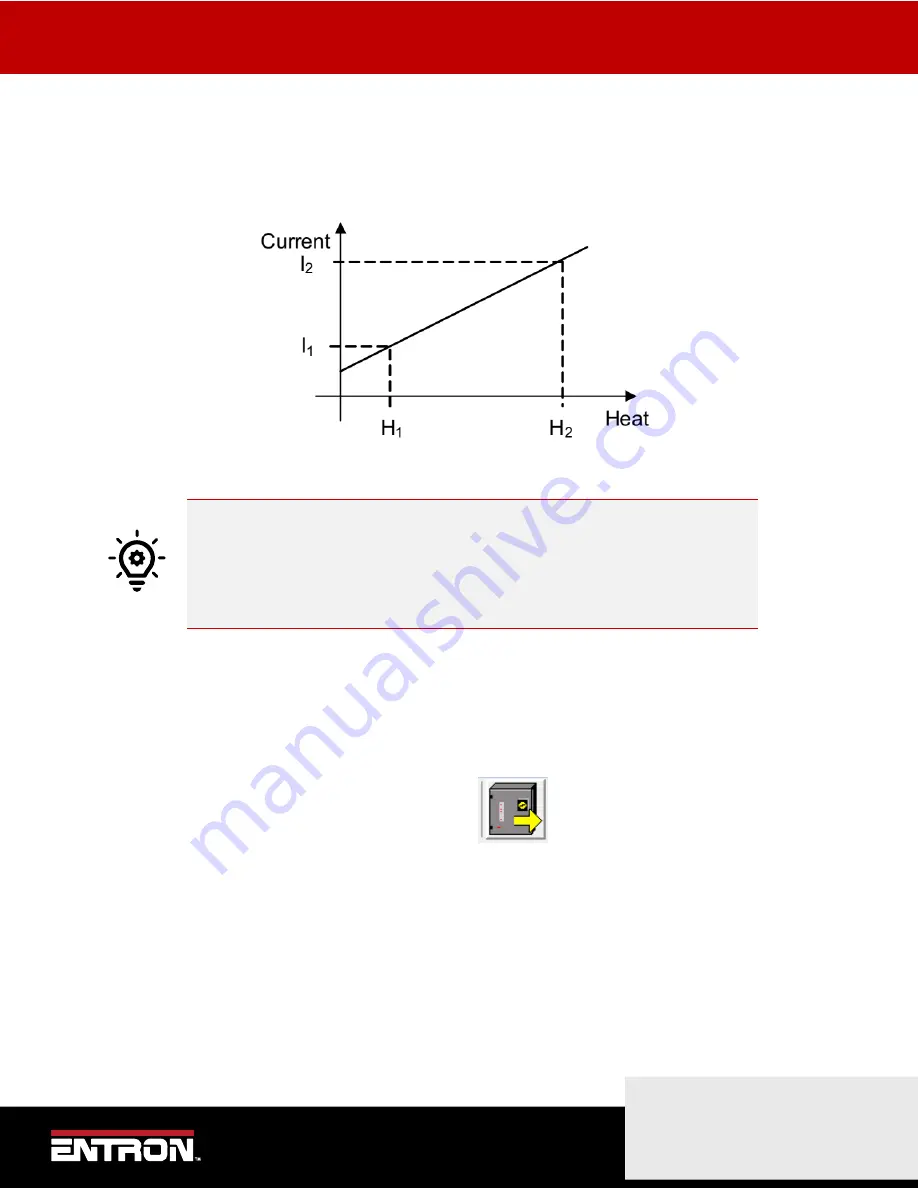

Calibration Procedure for Constant Current Calibrated Mode (“CCC”)

To use the iPAK2v2 in

CCC

mode where the weld current parameter is defined in terms of kiloampere (kA), the

relationship between Heat and Current must be established for the machine or system. The relationship is defined by a

two-point lookup table.

Figure 15: Constant Current Calibrate ("CCC") Diagram

Projection Welding Performance

CCC Calibration should be done for Projection Welding applications. CCC Calibration

increases the rise-time to the target current without causing any significant

transient conditions. Rapid-rise time of the weld current minimizes excessive

heating of the weld. Excessive heating can reduce weld strength.

The steps for calibrating CCC -constant current calibrated mode are as follows:

1)

Connect the computer to the control via an Ethernet cable

2)

Turn ON the iPAK2v2 weld control

3)

Open NetFlash™ software application on computer and connect to the target control

4)

Load the parameters from the connected control by clicking

the Load From Control

Icon

5)

Navigate to the

Program

tab in NetFlash™