PROGRAMMING WELD PROGRAMS

Weld Program Types

98 |

P a g e

Copyright © 2021 BF ENTRON and/or its affiliates. All rights reserved

Product Model:

iPAK2v2

Firmware Version:

V2.10

May 22 | Doc No 700253-2

1)

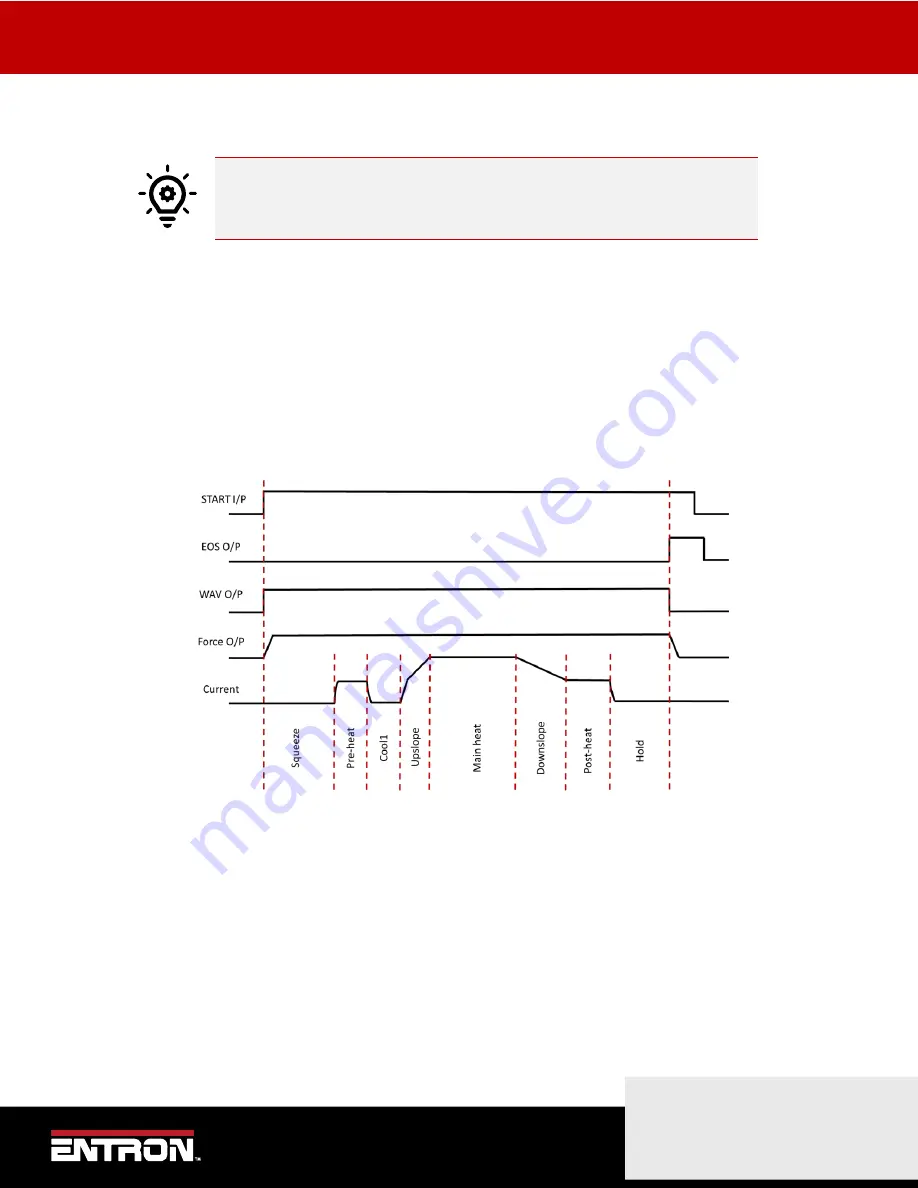

Pre-squeeze and squeeze time for the actuator to reach the desired weld force.

2)

A pre-heat weld pulse followed by a cool pulse is applied to heat the workpiece.

Galvanized Steel

A pre-heat pulse is typically used when welding galvanized steel to burn the zinc

coating off the base material.

3)

An upslope pulse is used to ramp the weld current to the main current in a controlled manner

4)

The main current is applied

5)

A downslope current is used to ramp the weld current to the post heat current in a controlled manner

6)

The post-heat is weld current is applied. Typically used to control the solidification of the weld nugget

and minimize cracking.

7)

A hold is used to allow the weld nugget to cool while still under force

8)

The End of Sequence (EOS) Output is generated when the sequence is complete.

Figure 28: Spot Weld Timing Diagram

5.4.1.2

Spot Pulsation

A spot weld with pulsation is a single point weld where the main heat weld current is repeated multiple times. A

pulsation spot weld is typically used to control the growth of the weld nugget without overheating the workpieces which

can result in expulsion.

A weld sequence timing diagram showing pulsation spot weld with the air valve actuated by the iPAK2v2 weld controller

and the main heat is pulsed three times to create the weld nugget is shown in

The weld program options are set as follows: