4

5

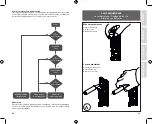

Indicators:

Green Led:

Indicates power on the receiver (alignment mode disabled)

On, at optimal signal (alignment mode enabled)

Yellow Led:

Indicates that the sensors can see each other

(alignment mode disabled).

Indicates sensor alignment signal strength by blinking

(alignment mode enabled).

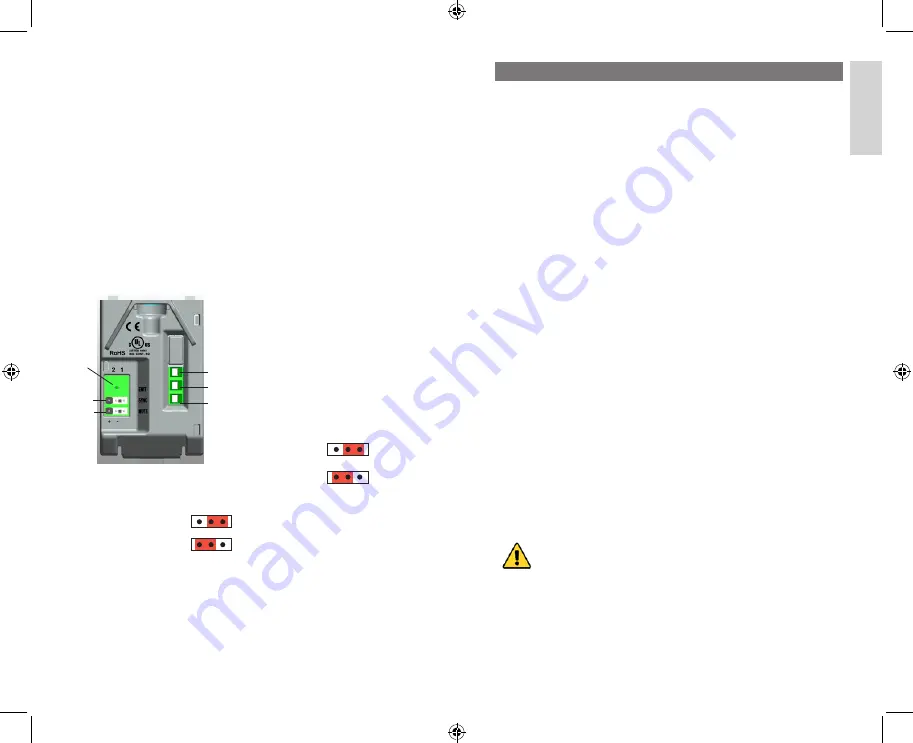

Connection to the receiver (ET-8060RX)

Wire connection: Function:

V+

18-34VAC/DC Supply Class 2

V-

18-34VAC/DC Supply Class 2

NO

NO relay output

C

COM relay output

NC

NC relay output. Safe mode

Green indicator:

This indicator shows that the sensor is

supplied and emitting infrared light.

Sync jumper:

The jumper must be enabled (position

2) when using two sets of sensors and

an AC supply. To prevent crosstalk

between the two sensor sets, the supply

cords must be crossed to synchronize

the emitter and receiver sets.

Position 1: Disable sync function

(default)

Position 2: Enable sync function

Mute jumper:

This jumper changes the function of the test/mute input.

Position 1: Test function active when mute input is connected to V+

(default)

Position 2: Test function active when mute input is connected to V-

Connection to the emitter (ET-8060TX)

Wire connection:

Function:

V+

18-34VAC/DC Supply Class 2

V-

18-34VAC/DC Supply Class 2

MU

Mute/Test input

Emitter (ET-8060TX)

V+

V-

MU

Sync

Mute

Green

LED

Warning

Safety precautions

This manual contains important information regarding safety during instal-

lation, we highly recommend that you read the manual carefully before in-

stalling the sensor. Save the manual for future use.

Installation and use must be carried out with respect to the latest laws,

provisions and rules in order to secure maximum safety.

According to the most recent European legislation, Industrial doors and

gates are listed in the Machinery Directive 98/37/CE and more specifical-

ly the provisions under EN13241-1; EN12453; EN12978 standards. As for

the North American market, the information is listed in the latest UL325

standards.

The information in this manual is to be used by a qualified fitters and is not

meant to be used by the end user of the door or gate.

The ET-8060 sensor must only be used as described in this manual. Im-

proper use may cause damage and personal injury.

• Do not modify or change any components unless it is specified in the

manual. Changes to the sensor can cause malfunctions. Entrya

Technologies disclaims any liability for damages due to modification of

the sensors.

• The sensor must only be used in through-beam installations and not in

a retro-reflective mode using a reflector.

• The sensor must be mounted on a solid vibration-free surface.

• The correct cable and conductor size is specified in the specifications.

• Make sure that the power supply and load currents as well as other

parameters are within the specification of the sensor.

For information concerning CE Declaration of Conformity, we refer to a

separate document.

Product description and applications

The ET-8060 through-beam photoelectric sensors are designed for pres-

ence detection (Type D according to EN12453) and can be used in indus-

trial doors and gates or similar applications that require detection of obsta-

cles interrupting the light beam from the emitter to the receiver.

The lenses can be mechanically adjusted, and they are adjustable ±100°

in the horizontal direction and ±30° in the vertical direction for correct op-

tical alignment between emitter and receiver – even on uneven surfaces.

(See fig. A and B). The sensor is encapsulated in a vandal-proof aluminium

cover.

Installation

The control system must be disconnected from the main pow-

er supply during installation. If backup batteries are present,

these must also be disconnected.

Check the following points before proceeding with the installation.

1. Check that the power supply is in accordance with the sensor specifi-

cation.

2. For distances between 0,6m…6m, 6m…12m or 12m…60m, see the

distance jumper settings in “Jumper settings and connections”.

3. The emitter sends out light in an angle less than ±5° (according to

ENGLISH