22

IPI SPECIFIC INSTRUCTIONS

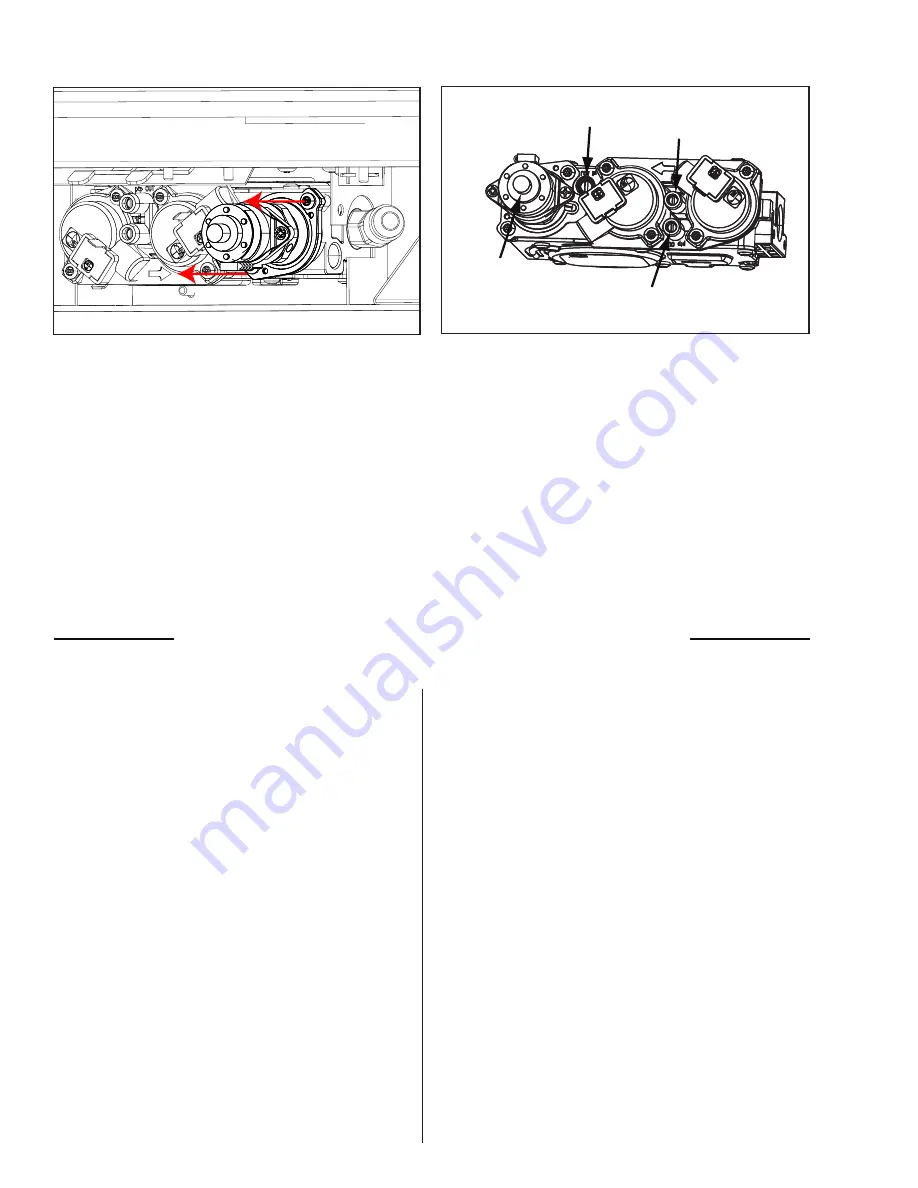

Pilot Adjustment

Screw

Manifold

Pressure Tap

Inlet

Pressure Tap

Stepper

Regulator

11.

7. Convert the SIT gas valve:

12.

Disconnect the wire harness from the IFC.

13.

Use a T-20 driver to remove the two screws that hold the servo regulator to the gas

valve. Remove the rubber regulator diaphragm that is situated between the servo regulator

and the valve body. The New servo regulator already has this diaphragm installed.

14.

Install the LP or NG servo regulator, with the new longer T-20 screws included in the kit.

15.

Re-connect the harness to the IFC.

16.

Reinstall the Burner, burner media and glass door.

1.

TESTING FOR LEAKS.

2.

Reconnect the electrical power to the unit.

3.

12. Relight the pilot and confirm the flame

properly covers both the thermocouple and

thermopile. Should the pilot require adjustment,

turn the adjustment screw clockwise to decrease

or counterclockwise to increase until the

4.

Relight the main burner in both the “HI” and

“LO” positions to verify proper burner ignition,

operation and proper flame appearance.

5.

Confirm the inlet and manifold pressures are

within the acceptable ranges as directed in section

Intial Intallation - Gas Line Connection and

Testing. If the E25 has been installed at

an altitude higher than 2000ft (610m) it is

required to de-rate the unit accordingly:

6.

In the USA: The appliance may be installed

at higher altitudes. Please refer to your American

Gas Association guidelines which state: the sea

level rated input of Gas Designed Appliances

installed at elevations above 2000 (610 m)

feet is to be reduced 4% for each 1000 feet

(305 m) above sea level. Refer also to local

authorities or codes which have jurisdiction in

your area regarding the de-rate guidelines.

7.

In Canada: When the appliance is installed at

elevations above 4500 feet (1372 m), the certified

high altitude rating shall be reduced at the rate

of 4% for each additional 1000 feet (305 m).

8.

14. MAKE SURE that the conversion

label is installed on or close to the rating

label to signify that the unit has been

converted to a different fuel type.

9.

f) Verify that if the conversion is from NG

to LPG, the screw must be re-assembled with

the red o-ring visible (refer to Figure 4). If the

conversion is from LPG to NG, The red o-ring

indicates which fuel the valve is set up for

Finalizing Conversion Nova & IPI