32

Always check for gas leaks with a soap and water solution after completing the

required pressure test.

Initial Installation

QUALIFIED INSTALLERS ONLY

g

as

L

ine

c

onnection

:

WARNING:

Only persons licensed to work with gas piping may make the necessary gas connections to

this appliance.

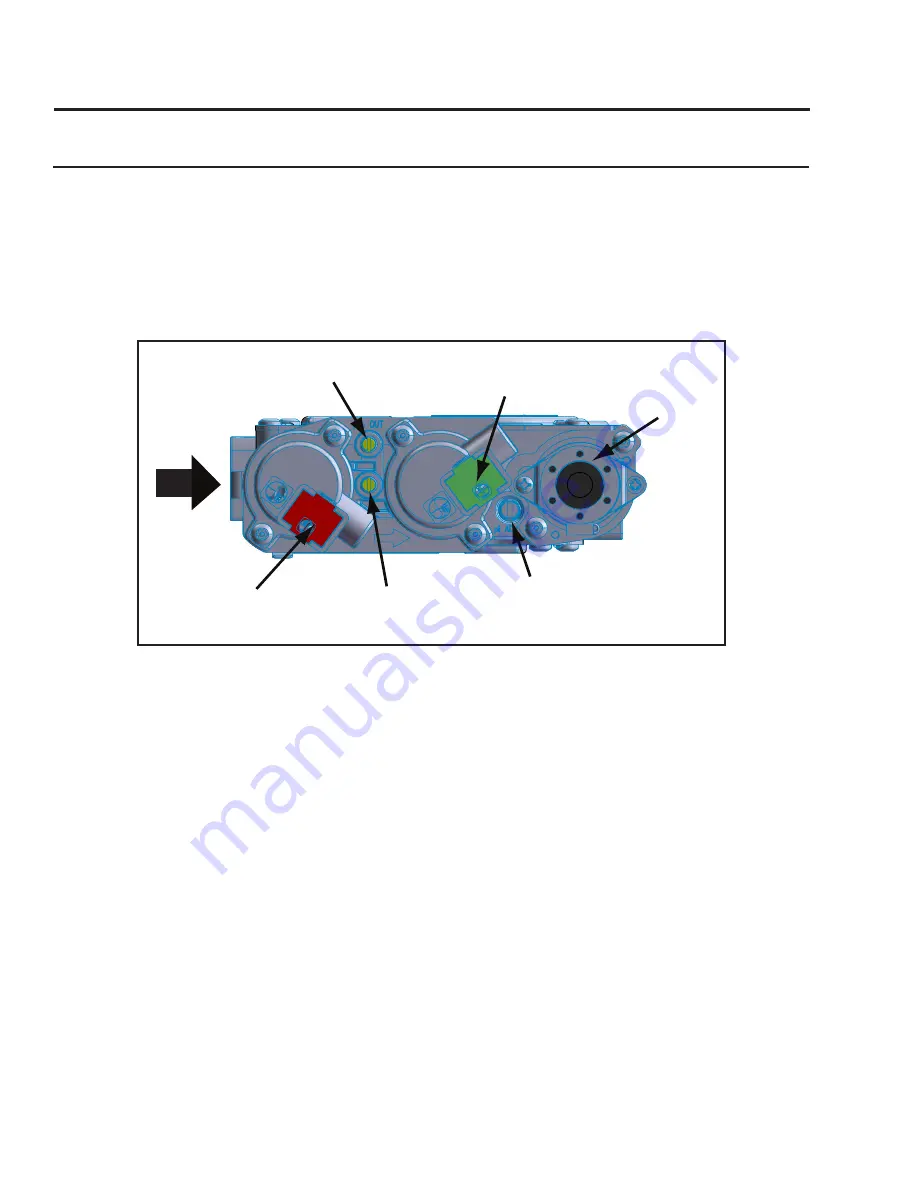

Fully Labeled Gas Valve.

Pilot

Adjustment

Screw

Manifold Pressure

Tap

Inlet

Pressure

Tap

Servo

Regulator

Pilot

Solenoid

Burner

Solenoid

Gas IN

TO TEST VALVE PRESSURES

The pressure taps are located on the valve

•

Turn set screw 1 turn counter clockwise to loosen,

•

Place

5

/

16

” (8 mm) I.D. hose over pressure tap system.

•

Check pressures using a manometer.

•

When finished, release pressure, remove hose & tighten set screw.

Gas Line Connection:

•

Prior to installation consult your local authorities codes or the CAN/CGA B 149 (1 or 2) installation

code in Canada, or in the USA gas installations follow either local codes or the current edition of the

National Fuel Gas Code ANSI Z223.1.

The appliance must be disconnected from the gas supply piping system during any pressure testing

where the pressure exceeds ½ PSIG (3.45 KPa) or damage will occur to the valve. The appliance must

be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than ½ psig (3.45

KPa).