c-c

ast

c

Eramic

b

afflE

i

nstallation

:

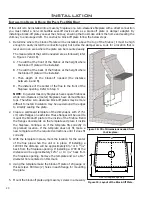

1. Slide the right C-Cast Ceramic Baffle in over the secondary air tubes at the top of the firebox. The tab

must be on the top and pointing towards the center and the smooth side is to face down.

Left Ceramic Baffle

Right Ceramic Baffle

Figure 24: Installation of C-Cast Ceramic Baffle.

Installation

f

an

w

irinG

d

iaGrams

:

This appliance, when installed, must be electrically connected and grounded in accordance with local

codes or in the absence of local codes, with the current CSA C22.1 CANADIAN ELECTRICAL CODE. Part

1, SAFETY STANDARDS FOR ELECTRICAL INSTALLATIONS, or THE NATIONAL ELECTRICAL CODE ANSI

/ NFPA 70 in the USA.

CAUTION Label all wires prior to disconnection when servicing controls. Wiring errors

can cause improper and dangerous operation. Verify proper operation after servicing.

DO

NOT

oil the fan bearings.

DO NOT

cut or remove the grounding prong from the plug.

DO NOT

route the power cord beneath the heater or away from the heat.

WARNING:

This appliance is equipped with a three-prong (grounding) plug for your protection against

shock hazard and should be plugged into a properly grounded three-prong receptacle.

2. Hook the outside edge of the baffle

over the top of the secondary air

chamber. This will make room to for the

installation of the left C-Cast Ceramic

Baffle.

3. Slide the left C-Cast Ceramic Baffle in

over the secondary air tubes. The tab

must be on the bottom and pointing

towards the center and the smooth side

is to face down.

4. Pull the baffles together in the middle

so the right tab rests on top of the left

tab. Ensure the baffles are flush with

the back and both sides of the firebox.

Note:

If the bolts on the flue collar are

not to the left and right of the hole, the

front secondary air tube will need to be

removed in order to install or remove

the C-Cast Ceramic Baffles. To remove

the front secondary air tube place a

screwdriver (any style except flat head)

into one of the air holes and tapping it

with a hammer/mallet to the left.

24

Summary of Contents for Kodiak 1200 FPI

Page 30: ...Notes 30 ...