Installation

Installation

m

asonRy

F

iRePLace

i

nstaLLation

:

A

non-combustible

manufactured

hearth pad (min. 24 gauge galvanized

steel or similar) must cover combustible

flooring underneath, as well as 6” (150

mm) in front of the heater and 6” (150

mm) to the side of the heater.

1. Install the hearth pad.

2. Lock any existing fireplace dampers

in the open position.

3. Set leveling leg to approximate

height.

4. Connect a Exhaust Starter Quick

Connect straight to the exhaust pipe.

5. This fireplace insert must be installed

with a continuous chimney liner

of 4” diameter extending from the

fireplace insert to the top of the

chimney. The chimney liner must

conform to the Class 3 requirements

of CAN/ULC-S635, Standard for

Lining Systems for Existing Masonry

or Factory-Built Chimneys and Vents,

or CAN/ULC-S640, Standard for

Lining Systems for New Masonry

Chimneys.

6. It is necessary to permanently seal

any opening between the masonry of

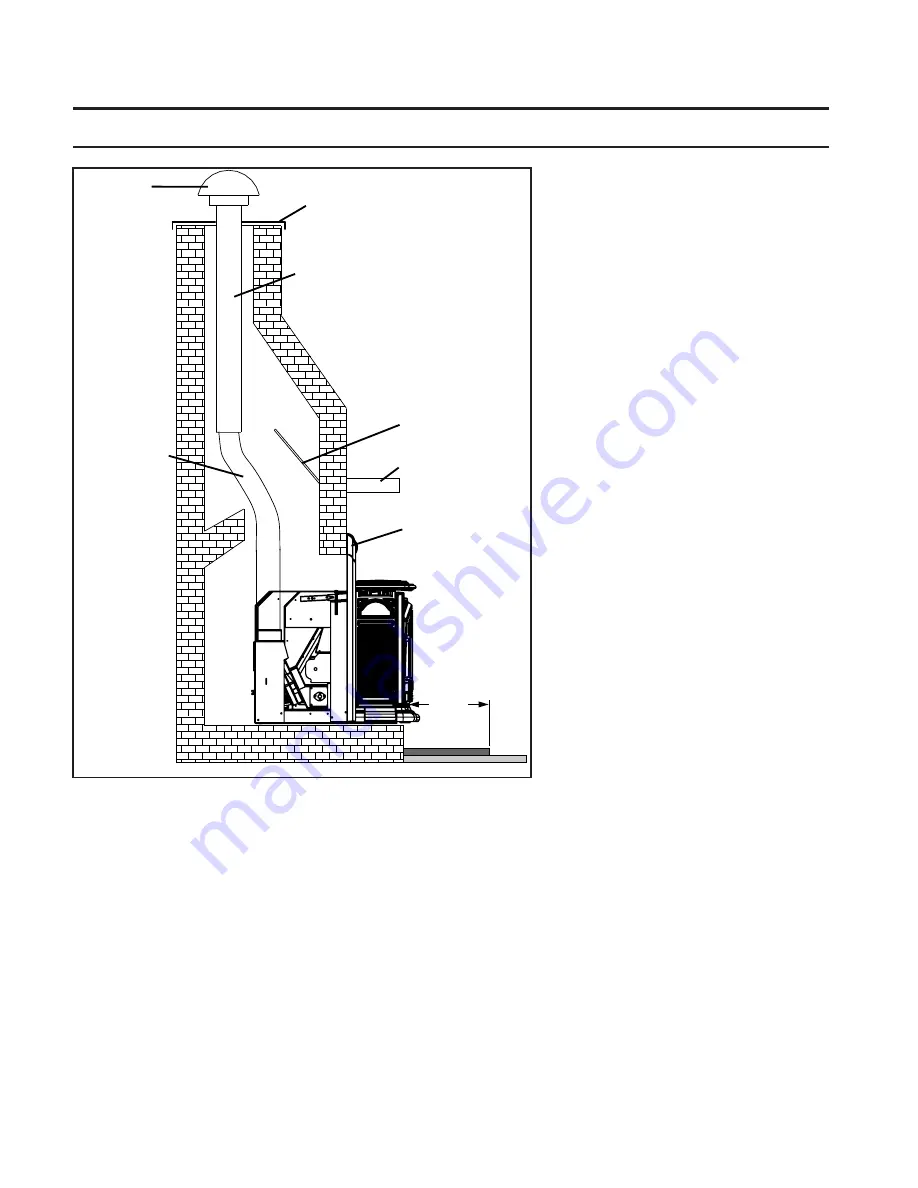

Figure 9: Masonry fireplace installation.

the fireplace and the facing masonry.

When installing the insert into a masonry fireplace, DO NOT remove any bricks or masonry, with the

following exception: masonry or steel, including the damper plate, may be removed from the smoke

shelf and adjacent damper frame, if necessary, to accommodate a chimney liner. Do this only if their

removal will not weaken the structure of the fireplace and chimney, and will not reduce protection for

combustible materials to less than that required by the national building code. When installing the

fireplace insert into a zero clearance fireplace, DO NOT cut or modify any factory firebox parts.

Floor Protection

Combustible Floor

Masonry Fireplace

Min 6"

(150 mm)

Rain Cap

Steel Plate or Flashing

Flexible or Rigid 4"

Stainless Steel Liner

12" (30.5cm) Mantle

Minimum 36" (91 cm)

from Bottom of stove

Damper Removed

or Fastened Open

Surround Panel

Flexible stainless

steel pipe

connection

21