ENVIRO-TEC

16

FORM ET115.24-NOM4 (819)

SECTION 1 - RECEIPT & INSTALLATION

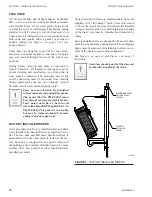

FIELD FURNISHED AND INSTALLED PIPING

OR RISERS

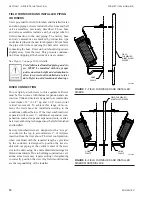

Units provided for field furnished and installed water

and drain piping or risers include the flex hose and ball

valve assemblies previously described. These hose

and valve assemblies include a stub of copper tube for

field connection to the unit piping. The factory hose

and valve assemblies are marked by connection type

and retracted inside the unit for shipment. Do not braze

the pipe stub without opening the ball valve and dis-

connecting the hose. Riser stub out should slope down

slightly away from the riser. This prevents condensa-

tion from dripping at the bottom of a riser column.

See

Figure 7 on page 16

for details.

Field fabricated/installed piping and ris-

ers MUST be installed with the proper

unit connection height and orientation to

allow for correct unit installation at a later

date. Refer to unit dimensional drawings.

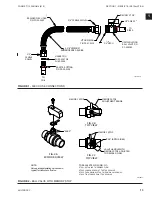

RISER CONNECTION

Do not rigidly attach risers to this equipment. Risers

must be free to move with thermal expansion and con-

traction. Units and risers are designed to accommodate

a maximum of 3” (1-1/2” up and 1-1/2” down) total

vertical movement. To achieve this range of move-

ment, the risers must be installed according to the

conditions outlined below. If the total combined riser

expansion will exceed 3”, additional expansion com-

pensation, such as loops and expansion joints, or alter-

nate riser anchoring techniques must be field furnished

and installed.

Factory furnished risers are designed with a “swage”

or socket in the top to accommodate 2” of tailpiece

insertion from the riser above. The riser configuration,

when combined with the required length as provided

by the customer, is designed to position the riser-to-

unit stub out piping at the vertical center of the riser

slot in the unit casing.

See unit submittal drawings for

dimensional details

.

Due to building construction vari-

ations, some risers may require cutting or lengthening

to correctly position the riser. Any field modifications

are the responsibility of the installer.

& INSTALLED

RISERS

FIELD

FURNISHED

HOSE

CLAMP

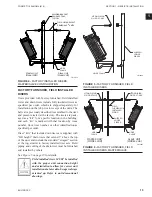

FIGURE 7 -

FIELD FURNISHED AND INSTALLED

RISERS

& INSTALLED RISERS

FIELD FURNISHED

HOSE

CLAMP

HOSE

CLAMP

FIGURE 8 -

FIELD FURNISHED AND INSTALLED

RISERS MASTER/SLAVE

LD13874

LD13875

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

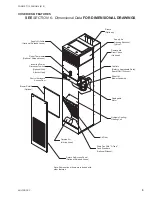

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...