ENVIRO-TEC

18

FORM ET115.24-NOM4 (819)

SECTION 1 - RECEIPT & INSTALLATION

FIELD RECONFIGURABLE RISERS AND

DISCHARGE OPENINGS

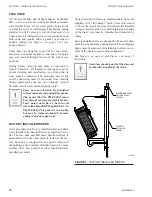

Riser Reconfiguration

Vertical Hi-Rise units are furnished with riser slot

“knockouts” in the casing back and both sides. Should

it be necessary to relocate risers in the field, the water

risers may be disconnected at the swivel joint on the

riser isolation valve, and removed from the unit. The

drain riser may be removed by moving the drain tube

hose clamp and removing the riser tube from the drain

hose.

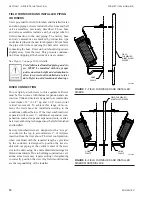

The water riser slot “knockouts” may be removed by

clipping the “tabs” to separate the inner portion of the

knockout. See

Figure 9 on page 18

for details

.

After

opening the riser slot, make a vertical slit in the cabinet

insulation with a sharp utility knife. This slit must be

centered left to right, and full height in the slot. The

water riser may now be re-installed at the desired loca-

tion by inserting the valve through the new opening.

Insert the valve through the opening with care to avoid

damage to the cabinet insulation. Make sure that the

swivel joint O-ring is undamaged, and re-attach the

hose to the valve with the O-ring in place. Replace-

ment O-rings (Part No. PR-07-0115) may be ordered

through the parts department.

INSULATION

SLIT CABINET

AS REQ'D

CLIP "TABS"

AS

REQ'D

CLIP

"TABS"

AS REQ'D

DRYWALL

STOP

FOLD OUT

FIGURE 9 -

KNOCKOUT REMOVAL

LD13876

After relocating all the risers, pressure test the joints to

assure system integrity.

The drain riser slot is already present on the back, left

and right sides. To install the drain riser, insert the riser

tube into the unit and connect the drain hose using the

hose clamp preciously removed.

After all the risers have been relocated, inspect the

cabinet insulation where the risers were removed, and

repair any insulation damage before starting the unit

and cover unused openings.

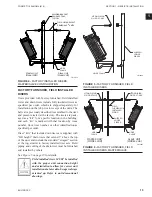

DISCHARGE OPENING RECONFIGURATION

Vertical Hi-Rise and Tandem Master & Tandem Slave

units are furnished with discharge opening “knock-

outs” in all four sides and the top. Should it be nec-

essary to reconfigure a unit for a different discharge

arrangement than originally provided, the new dis-

charge opening may be created by clipping the tabs of

the desired opening to remove the inner portion of the

“knockout”. The side flanges may then be folded out to

provide the drywall stops for the opening. See

Figure 9

on page 18

for details.

After the new opening is created, the cabinet insulation

must be trimmed out, and the edges of the insulation

should be coated with duct board adhesive or appropri-

ate liner tape to prevent erosion into the airstream.

Any unused discharge openings must have the drywall

stops bent back flush with the unit casing. The open-

ing must then be covered with an insulated plate. Any

cover plates and insulation must be provided and in-

stalled by others.

Relocating a discharge opening on a double discharge

unit may require removal or relocation of any factory

provided sight and sound baffle. Consult the factory

for details on requirements and relocation of sight and

sound baffles.

Size 10 and 12 units factory furnished

with double discharge do not have dis-

charge “knockouts” to allow field conver

-

sion to a single discharge. Consult the

factory for details.

The manufacturer assumes no responsibility for unde-

sirable system operation due to improper field design,

equipment or component selection, and/or installation

of ductwork, grilles, and other related components.

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...