ENVIRO-TEC

23

FORM ET115.24-NOM4 (819)

2

SECTION 2 - START-UP

GENERAL

Before beginning any start-up operation, the start-up

personnel should familiarize themselves with the unit,

options and accessories, and control sequence to un-

derstand the proper system operation. All personnel

should have a good working knowledge of general

start-up procedures and have the appropriate start-up

and balancing guides available for consultation.

The building must be completely finished including

doors, windows, and insulation. All internal walls and

doors should be in place and in the normal position.

In some cases the interior decorations, curtains and

furniture may influence overall system performance

by blocking return or supply air openings. The entire

building should be as complete as possible before be-

ginning any system balancing. Operation of the unit

during construction is not recommended since con-

struction dust will foul filters and coils and can seri-

ously degrade unit performance.

The initial step in any start-up operation should be a

final visual inspection. All equipment, duct-work, and

piping should be inspected to verify that all systems are

complete and properly installed and mounted and that

no construction debris or foreign articles such as paper

or drink cans are left in the units.

Fan coils are not intended for temporary

heat/cool or ventilation. Units are not

designed or equipped to operate in dusty

construction environments. Operation

of the units in conditions outlined above

could result in damage.

Each unit should be checked for loose wires, free

blower wheel operation, and loose or missing access

panels or doors. Except as required during start-up and

balancing operations, no fan coil units should be oper-

ated without all the proper duct-work attached, supply

and return grills in place, and all access doors and pan-

els in place and secure. A clean filter of the proper size

and type must also be installed. Failure to do so could

result in damage to the equipment or building and fur-

nishings, and/or void all manufacturers’ warranties.

COOLING/HEATING SYSTEM

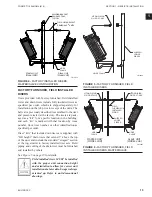

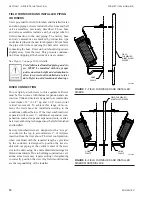

Prior to the water system start-up and balancing, the

chilled/hot water systems should be flushed to clean

out dirt and debris, which may have collected in the

piping during construction. During this procedure, all

unit service valves must be in the closed position. This

prevents foreign matter from entering the unit and clog-

ging the valves and metering devices. Strainers should

be installed in the piping mains to prevent this material

from entering the units during normal operation.

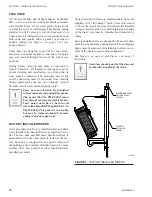

During system filling, air venting from the unit is ac-

complished by the use of the standard manual, or op-

tional automatic, air vent fitting installed on the coil. In

the case of the manual air vent fitting, the screw should

be turned counterclockwise no more than 1-½ turns to

operate the air vent. Automatic air vents may be un-

screwed one turn counterclockwise to speed initial

venting but should be screwed in for automatic venting

after start-up operations.

The air vent provided on the unit is not

intended to replace the main system air

vents and may not release air trapped in

other parts of the system. Inspect the en-

tire system for potential air traps and vent

those areas independently as required.

In addition, some systems may require

repeated venting over a period of time to

properly eliminate air from the system.

Do not exceed 300 PSIG operating pres-

sure.

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...