ENVIRO-TEC

24

FORM ET115.24-NOM4 (819)

SECTION 2 - START-UP

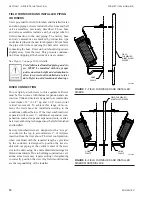

AIR SYSTEM BALANCING

All ductwork must be complete and connected, and

all grilles, filters, and access doors and panels must be

properly installed to establish actual system operating

conditions BEFORE beginning air balancing opera-

tions.

Each individual unit and associated ductwork is a

unique system with its own operating characteristics.

For this reason, air balancing is normally done by bal-

ance specialists who are familiar with all procedures

required to properly establish air distribution and fan

system operating conditions. These procedures should

not be attempted by unqualified personnel.

After the proper system operation is established, the

actual unit air delivery and the actual fan motor amper-

age draw for each unit should be recorded in a conve-

nient place for future reference such as the inspection,

installation, and start-up check sheet

(

see

SECTION

4 - INSPECTION, INSTALLATION & START-UP

CHECKLIST).

Contact the Sales Representative or the

factory for additional copies of this sheet.

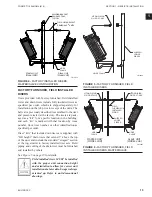

WATER SYSTEM BALANCING

A complete knowledge of the hydronic system, its

components, and controls is essential to proper water

system balancing and this procedure should not be at-

tempted by unqualified personnel. The system must

be complete and all components must be in operating

condition BEFORE beginning water system balancing

operations. All connections must be checked to ensure

they are adequately tightened after shipment; compo-

nents may loosen during shipment to job site

Each hydronic system has different operating charac-

teristics depending on the devices and controls in the

system. The actual balancing technique may vary from

one system to another.

After the proper system operation is established, the

appropriate system operating conditions such as vari-

ous water temperatures and flow rates should be re-

corded in a convenient place for future reference such

as the inspection, installation, and start-up check sheet

(

see

SECTION 4 - INSPECTION, INSTALLATION &

START-UP CHECKLIST).

Before and during water system balancing, conditions

may exist which can result in noticeable water noise or

undesired valve operation due to incorrect system pres-

sures. After the entire system is balanced, these condi-

tions will not exist on properly designed systems. If

unit is ordered with P.T. ports, these should be used to

measure the pressure differential across the coil.

CONTROLS OPERATION

Before proper control operation can be verified all

other systems must be in proper operation. The correct

water and air temperatures must be present for the con-

trol function being tested. Some controls and features

are designed not to operate under certain conditions.

A wide range of controls and electrical options and

accessories may be used with the equipment covered

in this manual. Consult the approved unit submittals,

order acknowledgement, and other manuals for de-

tailed information regarding each individual unit and

its controls. Since controls and features may vary from

one unit to another, care should be taken to identify

the controls to be used on each unit and their proper

control sequence. Information provided by component

manufacturers regarding installation, operation, and

maintenance of their individual controls is available

upon request.

Fan coil units, which allow water flow

through the coils while the fan is in the

OFF position, can create condensation on

the exterior of the cabinet.

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...