ENVIRO-TEC

33

SECTION 2 - START-UP

FORM ET115.24-NOM4 (819)

2

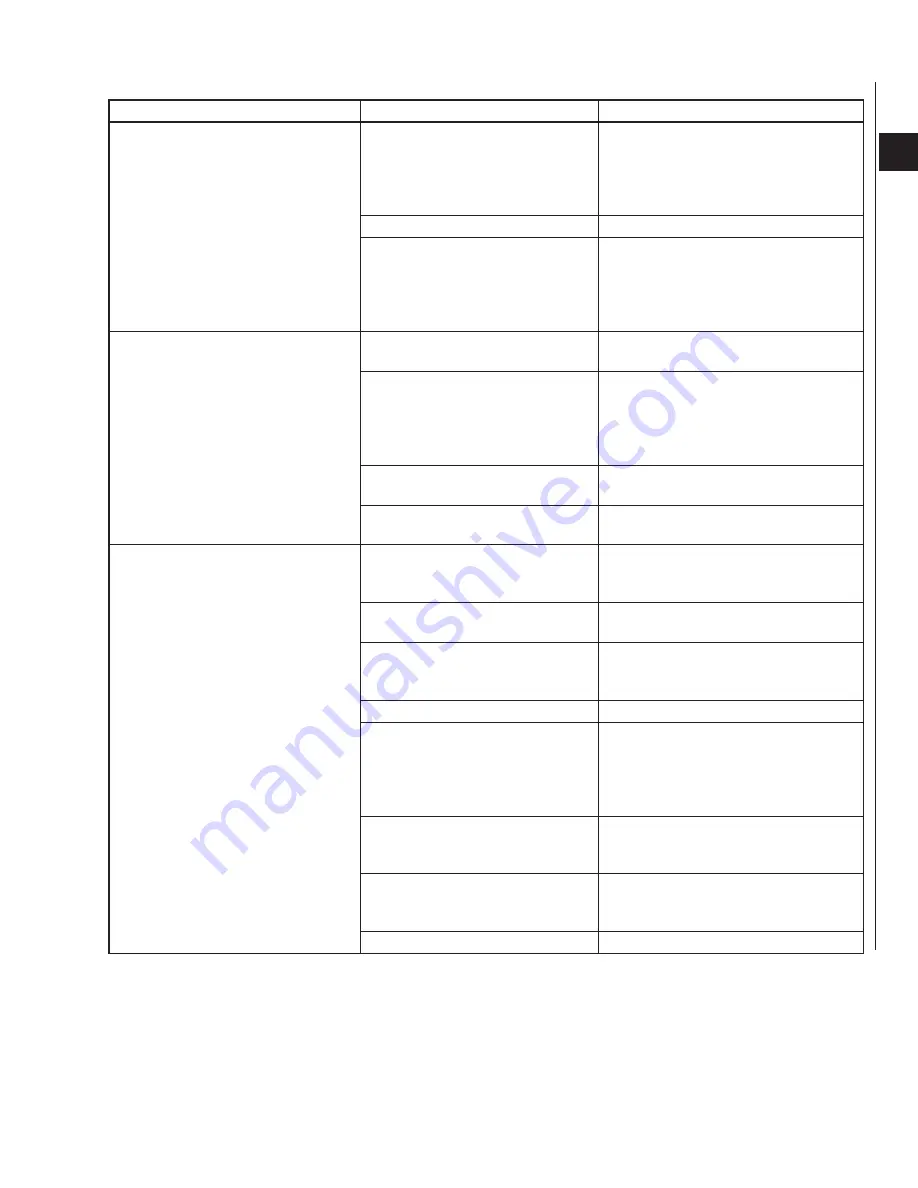

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Motor surges

Fan speed adjustment outside

operating range

Refer to Fan Calibration curve on unit.

Adjust speed on PWM Controller to

value that will allow motor to start. See

instructions for

Adjusting EC Motor Speed

on page 27

.

Blower Screw loose

Tighten Screw onto motor shaft.

ESP (external static pressure) too

high

Verify dampers, if present, are not closed.

Verify there are no obstructions in the

discharge ductwork and/or at the plenum

opening. Verify filter is not dirty and does

not obstruct airflow.

Poor performance

Lack of required external static

pressure

Add required external static pressure.

Speed adjustment outside fan

operating range

Refer to Fan Calibration curve on unit.

Adjust speed on PWM Controller to

value that will allow motor to start. See

instructions for

Adjusting EC Motor Speed

on page 27

.

Erratic speed command (in

Proportional Control mode)

Verify 2-10V analog signal at Remote

Control Input terminals.

Damaged or blocked blower

Verify blower rotates freely. Clear

blockage.

Motor starts but stops

Voltage or ground loss at motor driver

Verify proper voltage and ground at motor

driver power terminals. Refer to Motor

Driver Connections for the EC motor.

Motor overloaded - blower binding

Clear blockage. Verify blower rotates

freely with motor disconnected.

Motor overloaded

Use amp meter to verify motor amps.

Verify motor rotates freely with power

disconnected. If not, replace motor.

Open ductwork for concealed units

Verify ducts sealed properly.

Motor overheated due to lack of

airflow

Verify dampers, if present, are not closed.

Verify there are no obstructions in the

discharge ductwork and/or at the plenum

opening. Verify filter is not dirty and does

not obstruct airflow.

PWM board error or faulted

Refer to

PWM Board Status LED on page

25

. Verify all connections. Push reset

button. Replace board if fault returns.

Motor driver failure

Replace motor (Constant airflow or

constant torque motors.) Replace driver

(Constant RPM motor.)

Damaged motor cable

Cable is integral to motor, replace motor.

TABLE 2

- EC MOTOR TROUBLESHOOTING GUIDELINES (CONT'D)

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...