ENVIRO-TEC

34

FORM ET115.24-NOM4 (819)

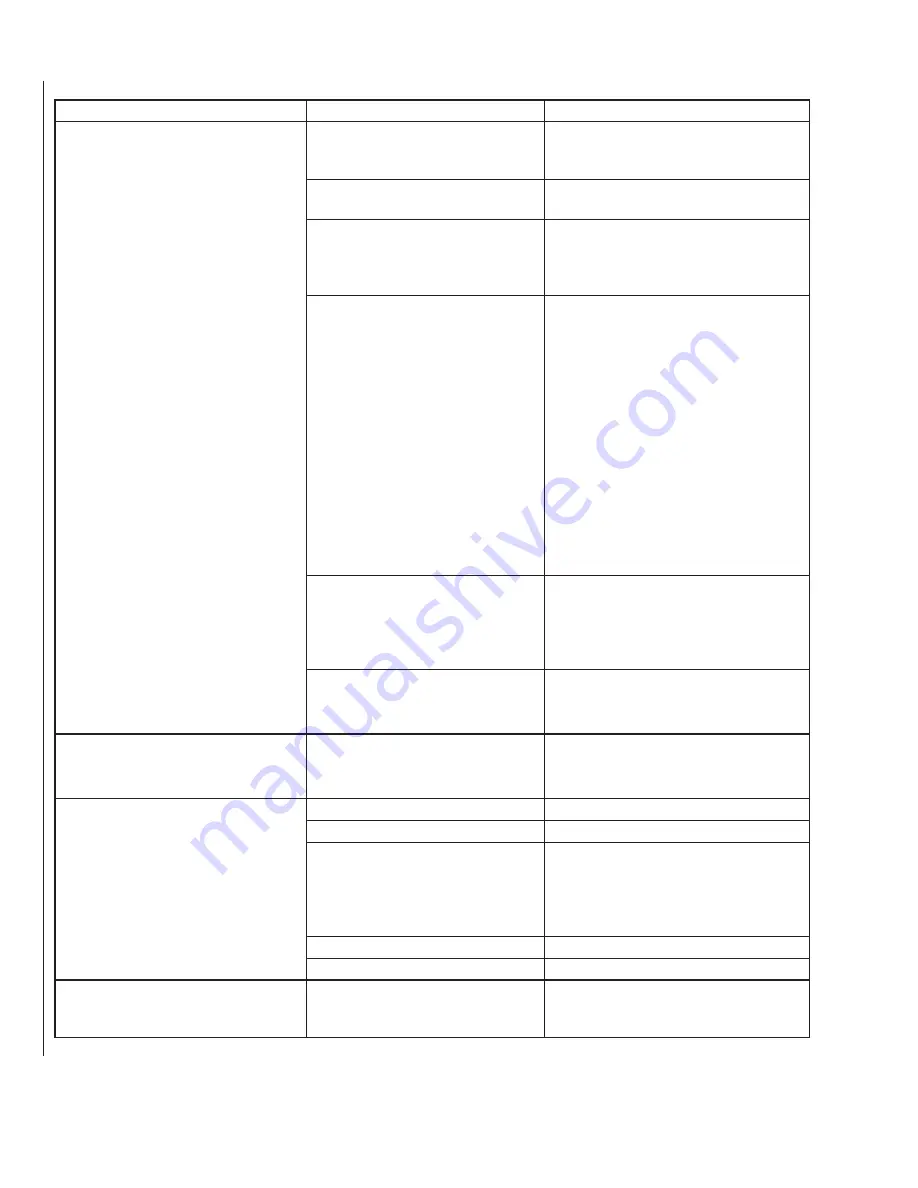

SECTION 2 - START-UP

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Motor speed cannot be adjusted

PWM board error or faulted

Refer to

PWM Board Status LED on page

25

. Verify all connections. Push reset

button. Replace board if fault returns.

Improper wiring connections

Verify wiring. If Fan Coil Relay board

present, verify all jumpers installed.

EC wiring harness damaged or

improperly seated

Unplug harness and re-install, making

sure plugs are fully seated. See section

on

Checking EC Wire Harnesses on page

35

. Replace harness if damaged.

No control signal (constant airflow

and constant torque)

Constant airflow and constant torque EC

motors will run at idle speed if they lose

PWM signal while enabled.

Verify PWM signal at motor connector

by connecting a multimeter set for “duty

cycle” between pins 1P1 and 1C (or

between pins 2P1 and 2C). The duty cycle

represents the on-time percentage signal

sent to the motor (this number will vary

between the minimum and maximum duty

cycle set by the factory). See

Figure 12 on

page 25

for PWM board connections.

Refer also to

PWM Board Status LED on

page 25

to verify board is in normal

operating mode.

ESP (external static pressure) too

high

Verify dampers, if present, are not closed.

Verify there are no obstructions in the

discharge ductwork and/or at the plenum

opening. Verify filter is not dirty and does

not obstruct airflow.

Motor driver failure

Replace motor (constant airflow or

constant torque motors)

Replace driver (constant RPM motors)

Motor runs in reverse, does not respond

to speed adjustment

Motor driver failure

Replace motor (constant airflow or

constant torque motors)

Replace driver (constant RPM motors)

Excessive motor noise

Motor mounting bolts loose

Tighten motor mounting bolts.

Motor bearing

Replace motor.

Motor overloaded

Use amp meter to verify motor amps.

Verify motor rotates freely with power

disconnected. If not, replace motor. Verify

static pressure within limits shown on Fan

Calibration Curve on unit.

Fan wheel rubbing on fan housing

Align wheel in housing.

Loose fan wheel

Align and tighten.

Motor runs in G3 PWM Program mode

but not in Run mode

Loose pin in Fixed Speed Conn.

harness

Verify that the pins in the Fixed Speed

Conn. harness (see location in

Figure 12

on page 25)

are inserted fully.

TABLE 2

- EC MOTOR TROUBLESHOOTING GUIDELINES (CONT'D)

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...