ENVIRO-TEC

39

SECTION 2 - START-UP

FORM ET115.24-NOM4 (819)

2

Procedure for Checking ECM Constant

Torque Wiring Harnesses

1.

Remove power from the unit. Lock and tag out

power source.

2.

Verify that equipment is properly grounded.

3. Unplug ECM Motor Power wiring harness, and

use ohmmeter to verify continuity (see

Table 12

on page 39

for details.)

4. Verify continuity from green wire (motor ground)

to equipment ground.

5. Unplug ECM Motor Signal wiring harness, and

use ohmmeter to verify continuity (see

Table 13

on page 40

for details.)

6. Replace all connections. Ensure good connections

are made.

Only very light force is required when

inserting meter probe into plug. Excess

force will damage contacts.

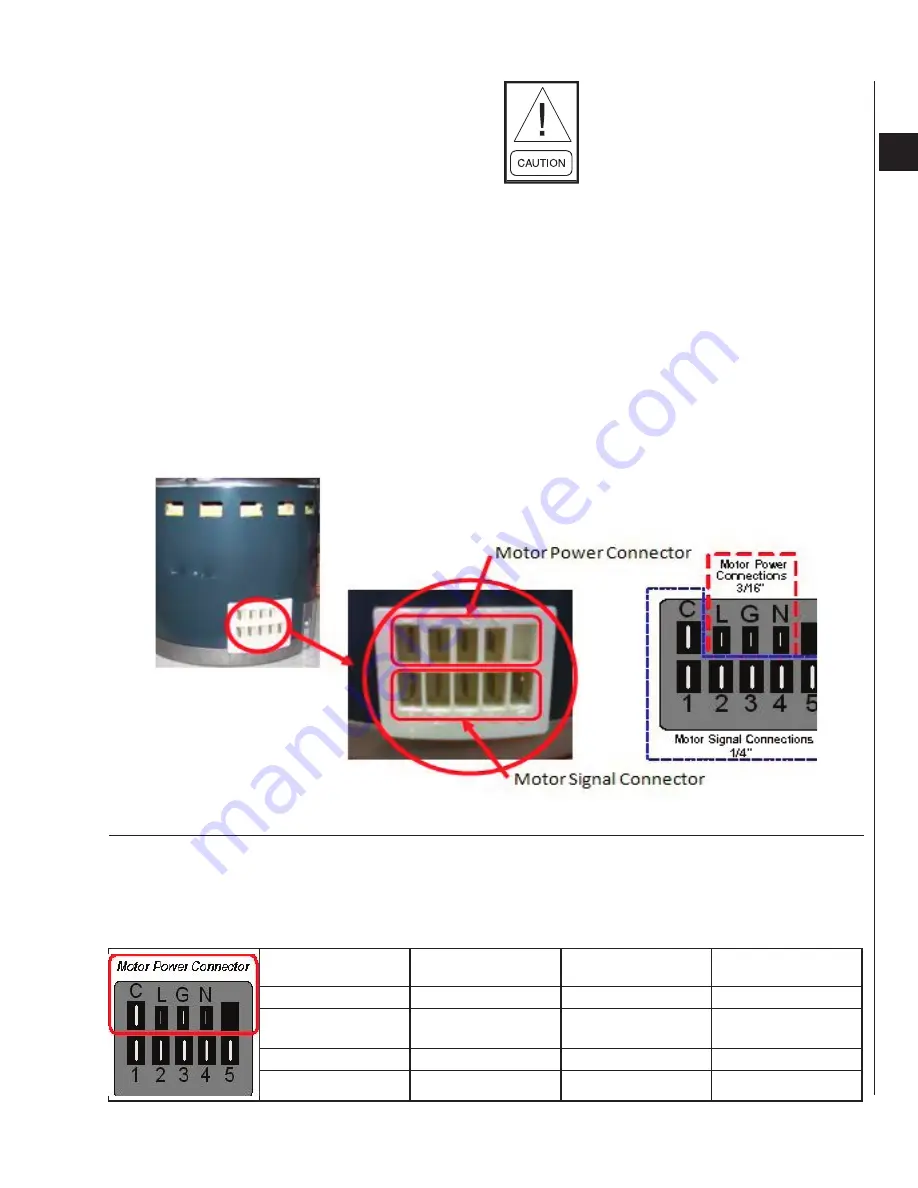

ECM Constant Torque Motor Connections

The ECM Constant Torque motor connector is located

on the side of the motor. It has two rows of terminals,

as shown in

Figure 29 on page 39

. The Power (4-

pin) connector plugs into the top row. The Signal (5-

pin) connector plugs into the bottom row.

FIGURE 29 -

MOTOR POWER AND SIGNAL CONNECTORS

TABLE 12 -

THE ECM CONSTANT TORQUE MOTOR POWER WIRING HARNESS

WIRE COLOR

FUNCTION

MOTOR

CONNECTION

FCRB CONNECTION

Purple

Signal Common

C

24 VAC - COM

Black

Line Voltage

L

Line Voltage In - see

equipment

Green

Ground

G

N/A - Ground

White

Neutral

N

P1 - L2/Neut

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...