ENVIRO-TEC

49

SECTION 5 - TROUBLESHOOTING

FORM ET115.24-NOM4 (819)

5

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

FAN MOTOR HUMS AND/OR

GETS HOT, BUT RUNS AT

REDUCED SPEED OR

NOT AT ALL

Improper power applied to

unit.

Apply proper power to unit.

Defective motor capacitor.

Replace with known good capacitor.

Defective fan motor.

Replace defective motor.

Blower wheel jammed in

housing.

Reposition blower wheel for proper alignment in housing,

or replace if damaged.

Foreign object in blower

wheel.

Remove foreign object and replace blower wheel if

damaged.

FAN RUNS BUT VIBRATES

Blower wheel dirty.

Remove and clean blower wheel taking care not to

remove or reposition balance weights.

Blower wheel bent.

Replace blower wheel.

Blower wheel out of balance.

Replace blower wheel.

Foreign object in blower

wheel.

Remove foreign object and replace blower wheel if

damaged.

Loose motor mount screws.

Verify proper motor and blower wheel position and

tighten motor mount screws. Do not crush mounting

grommets.

Broken motor mount frame or

mounting screws.

Replace motor or mounting screws.

FAN RUNS BUT BLOWER

WHEEL RUBS HOUSING

Bent blower wheel.

Replace blower wheel.

Blower wheel not positioned

properly on motor shaft.

Check for damage to blower wheel. Reposition blower

wheel on motor shaft or replace as required.

FAN RUNS BUT AIR

DELIVERY IS LOW

Incorrect fan speed has been

selected.

Reselect proper fan speed as required.

Dirty air filter.

Replace air filter.

Dirty coil.

Clean coil.

Obstruction in ductwork.

Check for improperly positioned balancing or fire

dampers. Check for fallen duct liner. Repair as required.

Actual E.S.P. higher than

design.

Check installation for proper supply and/or return grilles,

and compliance with plans and specifications.

FAN RUNS BUT NO COOLING/

HEATING. (HYDRONIC UNITS)

No chilled/hot water flow in

system.

Establish chilled/hot water flow in system as required.

Unit isolation valves closed.

Open unit isolation valves.

Debris in water piping

blocking flow.

Locate and clear debris from water piping as required.

Plugged strainer on units so

equipped.

Clean or remove strainer screen as required.

Riser or main flushing loop

open.

Close flushing loop valve as required.

Loose or improper wiring from

thermostat to control valve.

Verify all wiring connections and terminations, and verify

proper wiring of thermostat.

Defective thermostat.

Momentarily jumper thermostat contacts to simulate

proper operation. Replace thermostat as required.

Defective control valve

actuator.

Manually place control valve in “open” position using

lever on actuator housing. Replace actuator as required.

Improper aquastat operation

on units so equipped.

Verify proper aquastat position and operation. Replace

as required.

Summary of Contents for VHA

Page 10: ...ENVIRO TEC 10 FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...ENVIRO TEC 41 SECTION 2 START UP FORM ET115 24 NOM4 819 THIS PAGE INTENTIONALLY LEFT BLANK ...

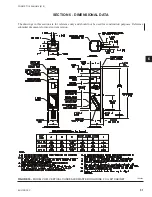

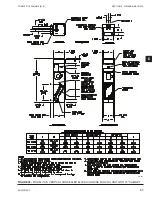

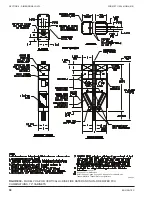

Page 54: ...ENVIRO TEC 54 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data 74 80083 ...

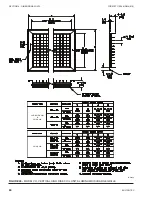

Page 78: ...ENVIRO TEC 78 FORM ET115 24 NOM4 819 SECTION 6 Dimensional Data NOTES ...